Koyo 6210 2RS Deep Groove Ball Bearing 50x90x20(mm) - 6210 2rs bearing

igus® GmbH would like to point out that it does not sell products from Allen Bradley, B&R, Baumüller, Beckhoff, Lahr, Control Techniques, Danaher Motion, ELAU, FAGOR, FANUC, Festo, Heidenhain, Jetter, Lenze, LinMot, LTi DRiVES, Mitsubishi, NUM, Parker, Bosch Rexroth, SEW, Siemens, Stöber and all other drive manufacturers mentioned on this website. The products offered by igus® are those of igus® GmbH.

The customer needed an alternative to metal for the mechanical drive technology of a pellet stove, as it seized up immediately and was too loud in operation. The solution: Deep groove ball bearing made from xirodur® A500. These even allow short-term temperature applications of up to 315 °C, are considerably quieter and 100 % free of lubricating grease.

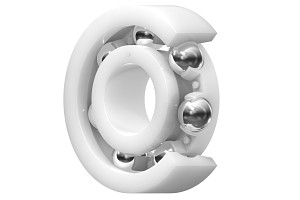

The suitability of a plastic ball bearing in accordance with DIN 625 is decisively determined by the materials of the two races. These are made from tribopolymers in order to maximise the service life and minimise the coefficient of friction. Various materials are available to choose from. They differ in terms of permissible temperature, media resistance and cost.

With just a few details about your application, our online tool will provide you with an overview of all suitable plastic ball bearings. You can also find out the expected service life of the ball bearing based on your application data.

Despite underwater use, the installed plastic ball bearings still function flawless without failures. The reason lies in the Lubrication-free and the Corrosion-resistant. Conventional metal roller bearings were out of the question, as they are dependent on constant lubrication.

![]()

The material of the bearing cage must also match the application. These materials are also very different in terms of chemical resistance and temperature. As part of the xiros-bearing delivery programme, the cages are already perfectly matched to the materials of the outer and inner rings.

The ball materials differ the most. In addition to stainless steel, glass, plastic and ceramic are also used. This alone results in a big difference in mass, which in turn has an influence on running smoothness, weight and media resistance. Stainless steel balls are cost-effective, resistant to chemicals, but have the highest weight. Glass balls should be selected if freedom from metal is important. They are also very resistant to chemicals and have a medium weight. Polymer balls have decisive advantages in terms of weight and quiet running behaviour. Depending on the plastic, polymer balls also have excellent chemical resistance.

The single-row xiros deep groove ball bearings are plastic ball bearings and belong to the roller bearing family. What are deep groove ball bearings anyway? For the most part, they are used to support radial loads, usually at high speeds. In exceptional cases, they are also suitable for supporting low axial forces. This is made possible by the close contact of the rolling elements with the grooves of the bearing.

test laboratory for plastic ball bearingsWe always put our plastic ball bearings through their paces in the largest test laboratory in the industry.

This 35 x 72 x 17 mm (6207-ZZ) bearing is a metric deep groove ball bearing. The 6207-ZZ inner diameter is 35 mm, the 6207-ZZ outer diameter is 72 mm, the 6207-ZZ width is 17 mm. This bearing has non-contact metal shields on both sides to protect the bearing from dust or any possible contamination, which can extend bearing life, and retain the lubricant in the bearing.

special part made of plasticFrom the idea to the customised solution: Your deep groove ball bearing in the shape, quantity and material of your choice.

Our deep groove ball bearings to DIN 625 do not require any additional lubricating greases or oils, are low-maintenance and, like other rolling bearings, consist of four components. However, the two races - consisting of an inner ring and outer ring - are available in different materials to meet a wide range of customer requirements. The cage of the bearing must also be adapted to the respective environmental conditions. Our ball bearings are equipped with stainless steel, glass, polymer or ceramic balls.

Our deep groove ball bearings made from high-performance plastics impress with their long service life and are ideal for a wide range of industrial applications. Whether in the food, beverage or semiconductor industry, for example, we have the right solution in various sizes available for you from stock. Visit our online shop to find the right deep groove ball bearing for your individual application.

The terms "Apiro", "AutoChain", "CFRIP", "chainflex", "chainge", "chains for cranes", "ConProtect", "cradle-chain", "CTD", "drygear", "drylin", "dryspin", "dry-tech", "dryway", "easy chain", "e-chain", "e-chain systems", "e-ketten", "e-kettensysteme", "e-loop", "energy chain", "energy chain systems", "enjoyneering", "e-skin", "e-spool", "fixflex", "flizz", "i.Cee", "ibow", "igear", "iglidur", "igubal", "igumid", "igus", "igus improves what moves", "igus:bike", "igusGO", "igutex", "iguverse", "iguversum", "kineKIT", "kopla", "manus", "motion plastics", "motion polymers", "motionary", "plastics for longer life", "print2mold", "Rawbot", "RBTX", "RCYL", "readycable", "readychain", "ReBeL", "ReCyycle", "reguse", "robolink", "Rohbot", "savfe", "speedigus", "superwise", "take the dryway", "tribofilament", "tribotape", "triflex", "twisterchain", "when it moves, igus improves", "xirodur", "xiros" and "yes" are legally protected trademarks of igus® GmbH/Cologne in the Federal Republic of Germany and possibly in some foreign countries. This is a non-exhaustive list of trademarks (such as pending trademark applications or registered trademarks) of igus GmbH or igus-affiliated companies in Germany, the European Union, the US and/or other countries or jurisdictions.

8613869596835

8613869596835