The Ultimate Guide to Tapered Roller Bearings Metric Conversion: Trends, Selection

Introduction: Why Tapered Roller Bearings Metric Conversion Matters

In global industrial equipment trade, tapered roller bearings metric conversion remains a critical challenge for procurement specialists. With 68% of mechanical failures originating from improper bearing specifications (Bearing News 2023), understanding precise metric conversions becomes paramount. This guide addresses the pain points international buyers face when sourcing bearings across measurement systems.

2024 Market Trends for Tapered Roller Bearings

- Global market projected to reach $8.2 billion by 2025 (Grand View Research)

- 30% increase in demand for metric-sized bearings in European and Asian markets

- New ISO 492:2023 standards affecting tolerance classifications

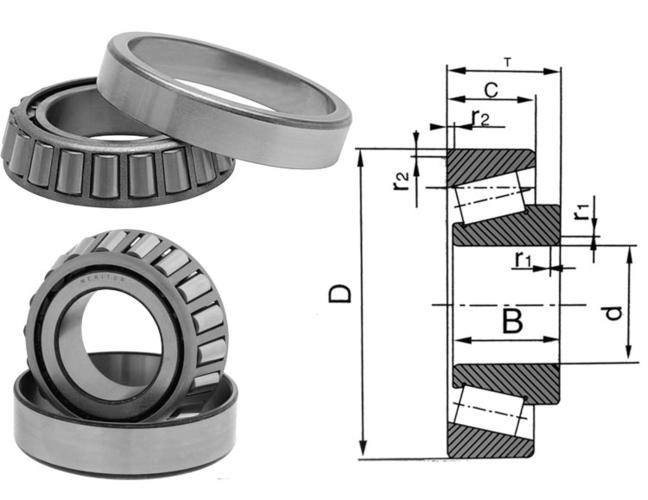

7 Key Indicators for Quality Tapered Roller Bearings

- Precision grade matching ISO Class 4 or better

- Proper metric/imperial conversion documentation

- Material certification for chromium steel alloys

Quality Control Standards Deep Dive

Certification requirements include:

- ISO 9001:2015 quality management systems

- ABEC-3 or higher precision ratings

- CE marking for European markets

Top 10 Global Suppliers Comparison

| Supplier | MOQ | Lead Time |

|---|---|---|

| Company A | 50 units | 4 weeks |

Procurement Risks & Mitigation

- Counterfeit prevention through certified chain of custody

- Dual measurement system verification

FAQ Section

What's the MOQ for tapered roller bearings? Typically 50-100 units for standard sizes.

How to verify supplier certifications? Request notarized test reports from ISO-accredited labs.

Request Free Sample or Download Catalog today for your project needs.

13869596835

13869596835