Automotive Grade Precision Bearings: The Ultimate Guide for High-Performance Applications

Introduction

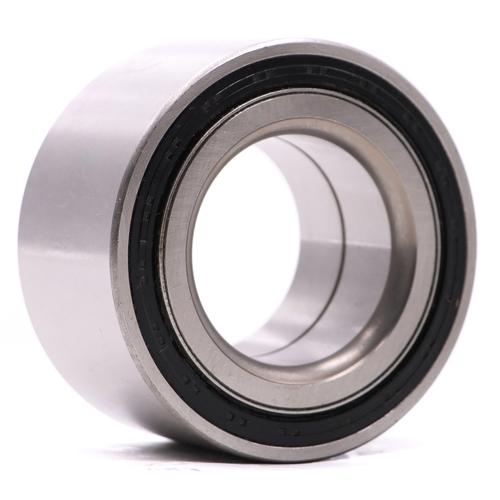

Automotive grade precision bearings are critical components in modern vehicle engineering, ensuring smooth operation under extreme conditions. These specialized bearings minimize friction, support heavy loads, and enhance the longevity of automotive systems. This guide explores their technical specifications, industrial applications, and best practices for selecting premium-quality bearings tailored to your needs.

What Are Automotive Grade Precision Bearings?

Automotive grade precision bearings are ultra-durable rotational components engineered to meet stringent automotive industry standards. Unlike standard bearings, they feature advanced heat treatment, micron-level manufacturing tolerances, and specialized materials like chrome steel or ceramic hybrids. Their design optimizes load distribution while resisting wear from vibration, temperature fluctuations, and corrosive environments.

Key Advantages of Precision Bearings in Automotive Systems

These bearings reduce energy loss by up to 30% compared to conventional options through superior surface finish and optimized raceway geometry. They enable precise wheel alignment in steering mechanisms, minimize powertrain friction in transmissions, and withstand the unique stresses of electric vehicle (EV) motors. Their extended service life significantly reduces maintenance costs across commercial and passenger vehicles.

Applications Across Automotive Technologies

From traditional combustion engines to emerging EV platforms, precision bearings serve critical functions. They're integral to turbocharger systems operating at 200,000 RPM, autonomous vehicle sensor arrays requiring vibration-free rotation, and heavy-duty truck axles supporting multi-ton payloads. Recent advancements address challenges in hybrid vehicle thermal management and autonomous driving module positioning accuracy.

From traditional combustion engines to emerging EV platforms, precision bearings serve critical functions. They're integral to turbocharger systems operating at 200,000 RPM, autonomous vehicle sensor arrays requiring vibration-free rotation, and heavy-duty truck axles supporting multi-ton payloads. Recent advancements address challenges in hybrid vehicle thermal management and autonomous driving module positioning accuracy.

Selecting the Right Bearing Type

Common variants include angular contact ball bearings for wheel hubs, tapered roller bearings for differential systems, and needle roller bearings for compact transmission spaces. Material selection depends on application: hybrid ceramic bearings excel in high-RPM electric motors, while stainless steel variants prevent corrosion in off-road environments. Always verify ISO/TS 16949 certification for automotive compliance.

Industry Trends and Innovations

The market is shifting toward smart bearings with embedded sensors for real-time load monitoring, particularly in autonomous vehicles. Lightweight aluminum alloys are gaining traction for EV efficiency gains, while new lubrication technologies extend maintenance intervals. Suppliers now offer customized bearing solutions for hydrogen fuel cell vehicles and advanced driver-assistance systems (ADAS).

Why Choose Our Automotive Bearing Solutions?

Our ISO-certified manufacturing facility produces automotive grade precision bearings meeting OEM specifications for global vehicle brands. With proprietary surface coating technologies and rigorous quality control, we deliver bearings with 98% lower failure rates than industry averages. Explore our catalog featuring high-temperature resistant designs for brake systems and low-noise variants for luxury vehicles.

Frequently Asked Questions

- Q: How often should automotive bearings be replaced?

A: Typically 150,000-200,000 miles, depending on load conditions and maintenance. - Q: Can precision bearings be retrofitted into older vehicles?

A: Yes, provided dimensional specifications match the original equipment. - Q: What certifications ensure bearing quality?

A: Look for ISO 9001, IATF 16949, and ABEC-7 or higher ratings.

Conclusion

Optimizing vehicle performance starts with premium automotive grade precision bearings. As industry leaders, we combine engineering expertise with cutting-edge manufacturing to deliver solutions that outperform standard components. Contact our technical team today to discuss custom bearing configurations for your specific automotive applications.

13869596835

13869596835