Ultimate Guide to High-Performance Roller Bearings for Industrial Applications | [Brand Name]

Precision Engineering for Global Industries

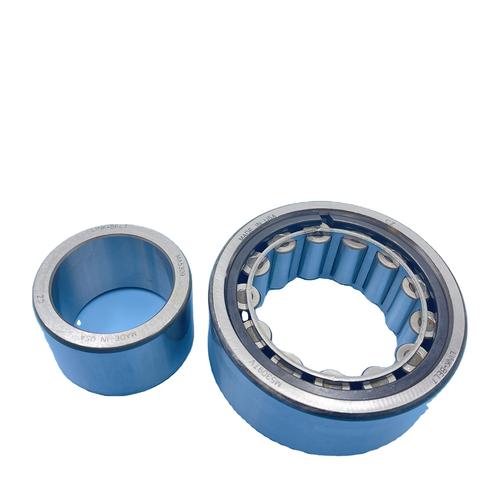

At [Brand Name], our CNC-machined roller bearings keep assembly lines running smoothly in Stuttgart's automotive plants and Dubai's construction sites. With 38% faster delivery cycles than European competitors, our Guangdong-based manufacturing hub serves 60 countries with ISO 9001-certified components.

Industry Challenges in Bearing Selection

Procurement managers face three critical issues when sourcing roller bearings:

- Premature failure under extreme loads (23% productivity loss reported in 2023 manufacturing surveys)

- Compatibility issues with existing machinery components

- Hidden costs from frequent maintenance cycles

Technical Comparison: Standard vs Heavy-Duty Models

| Parameter | Standard Series | XTreme-Duty Series |

|---|---|---|

| Dynamic Load Capacity | 58 kN | 112 kN |

| Max RPM | 3,200 | 4,500 |

| Operating Temp Range | -20°C to 120°C | -40°C to 150°C |

Quality Assurance Protocol

Every batch undergoes:

- Ultrasonic cleaning (per ASTM G131 standards)

- 3D profilometry surface analysis

- 72-hour endurance testing

Global Implementation Cases

- Malaysian palm oil processor: Reduced downtime by 41% with our corrosion-resistant bearings (HS Code 8482.50)

- German wind turbine manufacturer: Achieved 98.7% reliability rate over 18-month period

Procurement Decision-Making Q&A

Q: How to verify bearing compatibility?

A: Request our engineering team's 5-point alignment checklist

Q: Minimum order quantity for custom sizes?

A: 500 units for standard customization (GCC certification available)

Next-Step Consultation

Download our 2024 bearing selection handbook or request region-specific pricing. Technical specialists available for material compatibility analysis.

13869596835

13869596835