Top 10 Factors to Consider When Choosing Anti Friction Bearings Suppliers in China

In modern industrial operations, anti friction bearings play a pivotal role in reducing mechanical wear and improving energy efficiency. As global manufacturers increasingly turn to China for precision components, selecting the right anti friction bearings suppliers becomes critical. This guide explores essential considerations while highlighting China's growing dominance in delivering cost-effective bearing solutions.

Understanding Anti Friction Bearings

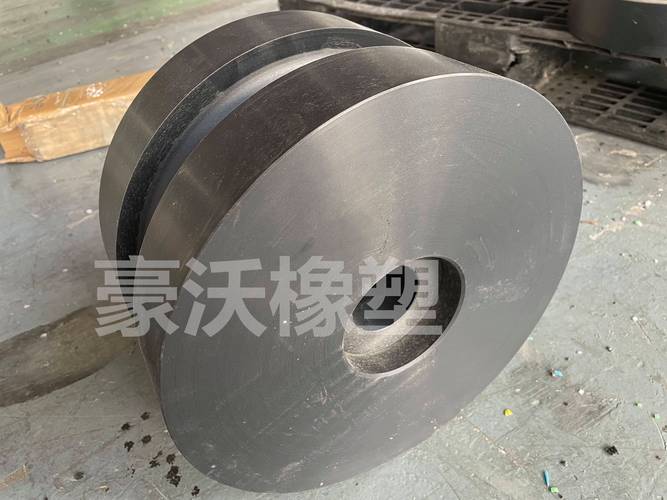

Anti friction bearings minimize rotational resistance through rolling elements like balls or rollers. Unlike plain bearings, these components significantly reduce torque requirements and heat generation. Chinese suppliers now produce advanced variants including deep groove ball bearings and tapered roller bearings, meeting international ISO standards.

Key Benefits of Chinese Suppliers

China's anti friction bearings suppliers offer competitive advantages through mature manufacturing ecosystems and strict quality control systems. Leading factories combine automated production with rigorous testing protocols, delivering products with 30% longer service life compared to conventional alternatives.

Industry Applications

From automotive transmission systems to wind turbine generators, Chinese-made bearings support diverse applications. Recent innovations include ceramic hybrid bearings for high-speed machinery and polymer cages for corrosive environments, demonstrating suppliers' technical capabilities.

Supplier Selection Criteria

Evaluate potential anti friction bearings suppliers in China through these parameters: 1) ISO 9001 certification 2) Material traceability 3) Customization capacity 4) MOQ flexibility 5) Third-party inspection reports. Reputable suppliers typically provide comprehensive technical documentation and application engineering support.

Market Trends

The global anti friction bearings market is projected to grow at 5.8% CAGR through 2029, driven by automation demands. Chinese suppliers are investing in smart manufacturing technologies, with 68% of major producers now implementing IoT-enabled quality monitoring systems.

Frequently Asked Questions

Q: How to verify Chinese bearing suppliers' credibility?

A: Check official CNAS certifications and request factory audit reports.

Q: What's the typical lead time from China?

A: Standard bearings ship within 2-4 weeks; custom designs require 6-8 weeks.

Q: Do Chinese suppliers offer bearing customization?

A> Yes, most provide tailored solutions including special coatings and dimensional modifications.

Partnering with reliable anti friction bearings suppliers in China ensures access to high-performance components at competitive pricing. Contact our engineering team today for personalized sourcing solutions backed by 15 years of industry expertise.

13869596835

13869596835