Industrial Bearings Catalogue PDF: Technical Specs

Precision Bearings for Global Industries: Solving Regional Challenges

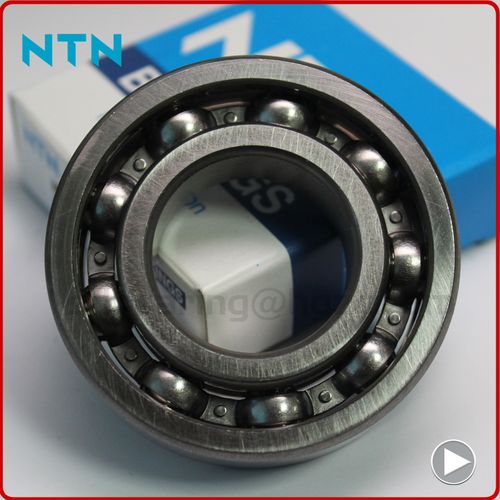

Manufacturers in Southeast Asia's automotive sector require bearings with extreme humidity resistance, while Middle Eastern construction equipment demands high-temperature tolerance. European precision machinery manufacturers seek ISO-certified components with micron-level accuracy. Our solutions address these regional needs through material science innovations and adaptive manufacturing processes.

How Do Modern Bearings Outperform Traditional Models?

| Feature | Standard Bearings | Our Solutions |

|---|---|---|

| Material | Standard Chrome Steel | AISI 52100 Ceramic Hybrid |

| Load Capacity | 12,000 RPM | 18,500 RPM |

| Temp Range | -20°C to 120°C | -40°C to 200°C |

| Service Life | 8,000 Hours | 15,000 Hours |

From Raw Material to Global Delivery: Our 8-Step Process

What Quality Assurance Can Buyers Expect?

- Certifications: ISO 9001:2015, DNV GL, BV Type Approval

- 3-Stage Inspection: Raw material analysis > Dimensional checks > Performance testing

- Traceability: Batch-specific QR code tracking

Cross-Border Procurement Made Simple

- MOQ: 500 units (mix models allowed)

- Lead Time: 15-25 days with EXW/FOB options

- Customs Support: HS code assistance COO documentation

Global Partners Trust Our Solutions

'Reduced downtime by 40% in our Indonesian assembly line' - PT Maju Industri, Jakarta

Smart Procurement Tips for International Buyers

- Schedule virtual meetings during GMT 8 business hours

- Prepare commercial invoice templates in advance

- Compare INCOTERMS 2020 options (FOB vs CIF)

Start Your Order Journey

1. Download Full Catalogue (PDF)

2. Request Free Sample Kit

3. Schedule Technical Consultation

13869596835

13869596835