$600 labor cost for water pump + timing belt kit ... - how much to replace a water pump and timing belt

When you bring your family’s car to Wiygul Automotive Clinic, we take your trust in us seriously. We take the time to get to know you and your vehicle. In addition, we will send you service reminders and maintain service records that help keep your car’s factory warranty valid - which means you don’t have to go to the dealer for service.

Polymer Concepts Technologies designs, engineers and manufactures state-of-the-art application-specific sealing solutions and high-performance polymer and fluoropolymer components. We take a collaborative technical approach with our customers and incorporate flexible designs, a vast material portfolio, and experienced manufacturing methodology to tackle the challenges of the most difficult applications. Our in-depth engineering experience, understanding of material characteristics, flexible service, rapid prototyping, and strong Total Quality Management System (AS9100D & ISO9001:2015) ensure an industry-leading solution every time.

When wheel bearings wear out, they can have a significant impact on vehicle performance, leading to increased friction and resistance within the wheel assembly. This extra friction forces the engine to work harder to maintain the same speed, resulting in decreased fuel efficiency. Additionally, worn bearings can cause uneven tire wear, as the compromised alignment and stability of the wheels lead to irregular contact with the road surface. Hitting a pothole or other road hazard can exacerbate bearing damage, potentially causing sudden bearing failure and loss of vehicle control. The deterioration of wheel bearings also affects the proper transfer of torque from the engine to the wheels, further compromising handling and increasing braking distance.

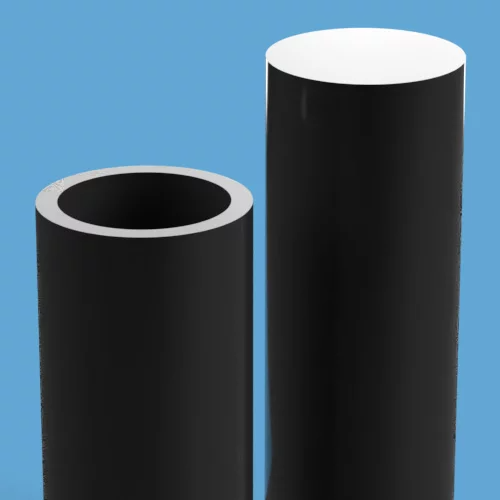

Material advantages in chemical resistance and ability to withstand aggressive compounds and environments. Excellent electrical insulation properties as well.

Brown aircraft tools

A: Typically, wheel bearings last between 85,000 to 100,000 miles, but this can vary based on driving conditions and maintenance.

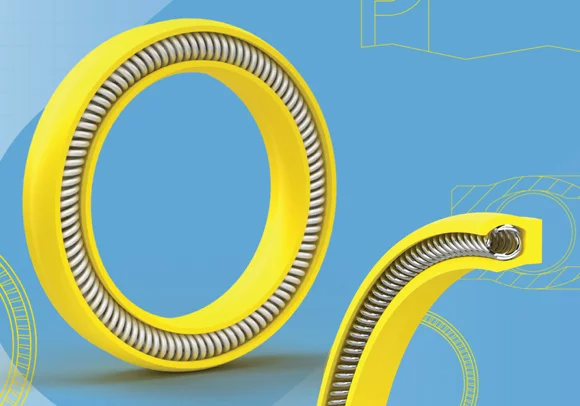

Typically used in rotary and reciprocating applications to seal against stainless steel, chrome plated components and aluminum alloys and/or ceramic coatings.

Wheel bearings are essential in the operation of your vehicle. More precisely, a wheel bearing is crucial for the proper function of the hub, tire, and wheel assemblies to work together. The wheel bearing allows friction-free movement and rotation of the hub assembly, and thereby provides smooth tire and wheel rotation. Worn-out or damaged wheel bearings can lead to a range of problems that affect vehicle performance and safety, making it essential for drivers to recognize the signs of trouble.

Aircraft seals and gaskets

Very High coefficient of friction, typically used in bearings, back up rings and bushings. Suitable as a metal alloy replacement.

Silicone PSeal

Tire Wear and Tear. What about your tires? We all know the importance of rotating your tires to promote even wear, but did you know a broken wheel bearing can lead to uneven tire wear too? The looseness of the wheel and the vibration that reverberates through the wheel cause your tires to wear unevenly, meaning you are more likely to have to invest in new tires sooner.

Aircraft PSeal

A: Common causes include poor maintenance, water and dirt contamination, extreme driving conditions, and manufacturing defects.

Unusual Noises Coming From the Wheels. Listen carefully. The most common and often most-identifiable symptom associated with a bad wheel bearing is noise coming from the wheel or tire area of the moving vehicle. You may mistake this as engine noise, but when you listen closely you will likely hear grinding or grating that gets louder as the vehicle accelerates. Since wheel bearings are not known for wearing out too frequently, the noise is typically suspected to be something else and the problem gets overlooked.

Seal design is a complex process, especially in aviation applications where certifications and rigorous zero-failure standards are a must to ensure that flight operations go smoothly and without catastrophic failure. We help you navigate those challenges with extensive hardware consulting, operations testing, seal qualifications, and customized seal cross-section design to meet your application requirements.

A: Driving with a bad wheel bearing is dangerous as it can lead to wheel failure and accidents. It should be addressed immediately.

You can rely on our promise of honesty and competence when we service your vehicle. Our customers know that they will get a fair price for services provided.

Vehicle Pulling to One Side While Driving. Are you doing the steering, or is the car driving where it wants to? When a wheel bearing corrodes or becomes pitted, the smooth exterior lining is gone and the vibration is transmitted to the tires which may feel like it is “pulling” to one side or the other. As the bearing on one side deteriorates, it puts more pressure on the opposite bearing, leading to uneven wear and increased friction. This uneven wear generates heat, which further accelerates the degradation of the bearing. As a result, the affected wheel may start to wobble or vibrate, robbing the vehicle of its stability and smooth handling, especially when cornering or driving at higher speeds.

These additional materials can improve wear resistant, reduce friction, and even alter the thermal properties of the seal.

Brown Aircraft Seals

We recognize the special operating requirements as set forth by our Aviation partners and have developed critical components that reduce maintenance time, increase operating cycles before needed replacement, help improve the overall safety of the operators and passengers aboard, increase cost savings per part and promote overall efficiency of our client's applications.

Car Feels Loose. Does your car feel loose? When you hear professional drivers talk about a “loose” car, you may not know what that means. It often refers to the steering of the vehicle, which can include wheel bearings. Wheel looseness, or also called wheel play, is another common symptom of a bad wheel bearing. As the bearing begins to wear down, they become loose inside the wheel hub and spindle, which makes your vehicle feel loose while steering.

Aerospace seals

Chances are when you start hearing a loud noise from under the hood of your car as you’re driving, you automatically think it’s an exhaust leak or your car is going to break at any moment. But have you thought about the possibility of a broken — or nearly broken — wheel bearing causing that noise?

Versatile Material, High/Low Temperature tolerances and low coefficient of friction. Low Dielectric Constant and inflammability.

A: While possible, replacing a wheel bearing requires specific tools and expertise. It’s recommended to seek professional help for accurate installation.

We want to take the stress out of getting your vehicle serviced. We’ll never talk down to you or pressure you, but we will be completely thorough honest about what your car does need - specifically noting anything that could be a safety issue.

Polycon 25 Variants are typically filled custom blends of Polycon 25 and other materials to meet the specific operating requirements of the application.

If you suspect you are driving with a broken — or nearly broken — wheel bearing, stop in and see us today. Our team of trained technicians will quickly assess and repair your vehicle and have you back on the road in no time!

We engineer, design, and manufacture high-performance seals and components for demanding Aviation applications. Polymer Concepts has been an Aircraft Component partner for more than 25 years supplying seals for a variety of Commercial, Government, and Military applications. Our Spring-Energized Seals and Rotary Lip seals, utilizing our extensive Material Polycon Library, can be found in the assemblies of Passenger Aircraft, Helicopters, and Defense Platforms.

8613869596835

8613869596835