10058-F4 | 99.95%(HPLC) | In Stock | Myc inhibitor - 10058

How long will awheel bearinglast once it starts making noise

In order to protect the bearing from contamination, sealing points must be provided in the structural design. These represent a barrier between the interior of the bearing and the environment.

For the radial support of the bearing a tight fit for the inner and/or outer ring is selected, depending on the application. For the fit of the bearing rings, the following criteria msut be checked before the design implementation:

Floating bearings, in which the displacement is realized within the bearings, are to be fixed like locating bearings. The graphic below shows an example with two cylindrical roller bearings of the type NJ.

First, the manufacturing-related edge conditions are examined. If the bearing is pressed onto its seat, its end face rests against the contact surface of the shaft or the housing. The edge conditions of the two touching surfaces must therefore be adapted to allow full surface fitting of the mating surfaces. The shaft and housing shoulder may be the only point of contact on the bearing. In principle, the edge condition on the shaft and housing seat must be smaller than the smallest edge condition of the bearing ring. As an alternative to a radius, an undercut can be incorporated into the shaft. For this, the contact surface must be ensured. Also, the notch effect should be taken into account in advance.

Humming, squealing, clicking, snapping, clunking, rattling, and knocking noises are all common if your HGV wheel bearing is bad. You may hear these noises when you accelerate, shift gears, or turn. They can also indicate a variety of other problems, so it’s important to have them checked as soon as possible.

How to checkwheel bearing

If the permissible deformation of the housing has been reached due to the forces acting, it must be reinforced. This stabilizes the outer ring and ensures the roundness of the bearing to a certain extent.

There are a number of warning signs that can indicate that your wheel bearings are beginning to fail. If you suspect your wheel bearings are starting to fail this should be investigated as quickly as possible.

If you suspect your wheel bearings are wearing out, they should be investigated immediately, and replacement bearings fitted if necessary.

If a vehicle pulls to one side when pressure is being applied to the brakes this indicates that something is wrong. It can signify a number of different issues but failing wheel bearings is one of the potential problems.

2024714 — Much like with grinding noises, you can tell which side of your car has the bad wheel bearing by listening to the rumbling sound that it makes.

Silicon carbide behaves almost like a diamond. It is not only the lightest, but also the hardest ceramic material and has excellent thermal conductivity.

The graphic below shows the axial fixing for non-locating bearings. The location depends on the model as well. For example, in the case of a bearing with a loose inner or outer ring both rings need to be axially located.

The axial locations listed above are the most commonly used fixings. Location with a lock screw is less common. Here, the spacer ring is pressed against the bearing outer ring with a screw that is integrated into the housing.

How long dowheelbearings last on a truck

The contact surface (shoulder) must also be designed in accordance with DIN 5418. The correct dimensioning of the shoulder height is particularly important because it ensures correct load transmission. The limits for the height dimensions are specified in the bearing tables. The respective radii and minimum heights are based on the radius or the chamfer of the corresponding bearing ring and cannot be universally specified.

If you feel that your vehicle is vibrating when you change speed or are turning, this might indicate that you need to replace your wheel bearings.

You should never drive any kind of vehicle without properly functioning wheel bearings. This is not only extremely dangerous for the driver, but it can also end up injuring or even killing other road users. If you ignore bad wheel bearings, your wheel might completely stop working, or you could face serious challenges when it comes to steering your HGV. Needless to say, both of these circumstances can be highly dangerous.

Our bearings can be disassembled into various parts, bearings can be replaced in the wind turbine nacelle without removing the blades.

For these reasons, it’s crucially important that HGV drivers, owners and operators keep checking on the state of the wheel bearings on their vehicles. If they fail the consequences can be dramatic and should always be avoided.

The lower right figure shows the wall thickness variable. Here, it is imperative that the strongest wall is located in the direction of the force, because the force and the opposite support point deform the material in between the most. The lateral and upper wall areas form a resistance against general deformation of the outer ring.

The distribution of support points on the housing is also very important. A rolling bearing connects rotating and non-rotating components in a machine. In most cases, the housing is connected to an adjacent structure. The correct arrangement of the support points must be ensured, as this determines the transfer of forces into the adjacent structure. If a support point is used for the housing, the force can only be transmitted to the surrounding components via this single point. Therefore, multiple support points have a positive effect on the balance of forces.

The quality of the wheel bearings that are fitted will make a difference, as too will your usual driving conditions. In the UK, where rain and bad weather frequently make for poor driving conditions, wheel bearings are under extra strain on a regular basis. If you drive in a rural area, perhaps on roads in relatively poor conditions, this too will reduce the service of your wheel bearings.

7310 Summitrose St. Tujunga, CA 91042. map-entry. $875,000. 3 beds. •. 2 ... mean they include using third-party advertising and analytics tools such as cookies.

A high-quality replacement wheel bearing, installed properly, will last up to roughly 100,000 miles if the grease is maintained. Depending on the vehicle, some ...

The bearing rings must be well supported over their entire circumference. This is in direct correlation to the load-bearing capacity of the bearing.

Wheel bearings play an important role in keeping your HGV safe and out on the road. They are important components of a vehicle’s braking, steering and suspension systems. The one-piece hub assembly is located between the brake disc or drums and the drive axle incorporates the hub, wheel bearings, ABS wheel speed sensor, and mourning flange. It’s the component that allows a wheel to turn.

The left bearing is a locating bearing. It has to support axial forces; thus, it needs to be axially located. The bearing on the right is a non-locating bearing. It does not have to support any axial forces and can move axially through an outer ring that is not axially located. An axial displacement of the bearing is thus possible, as occurs, for example, in the event of thermal expansion.

2024628 — 61812355 ...

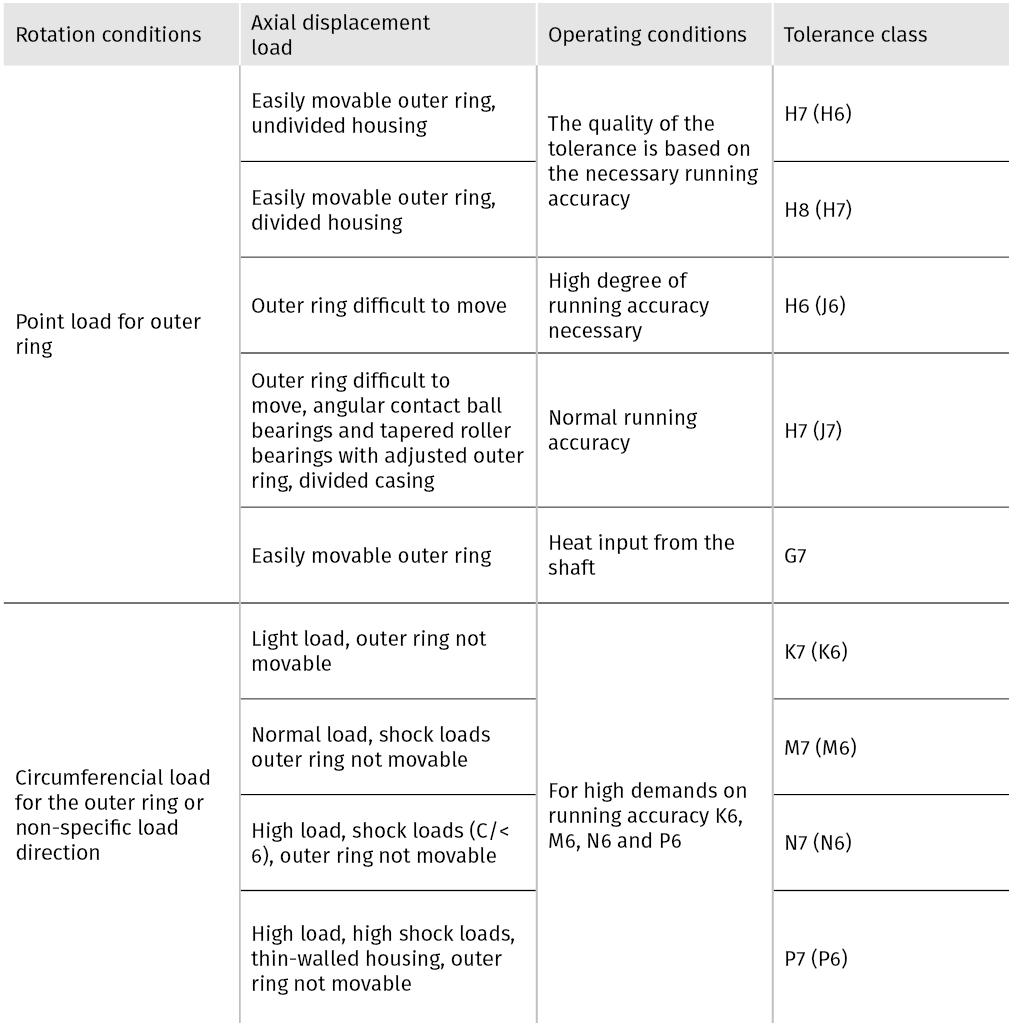

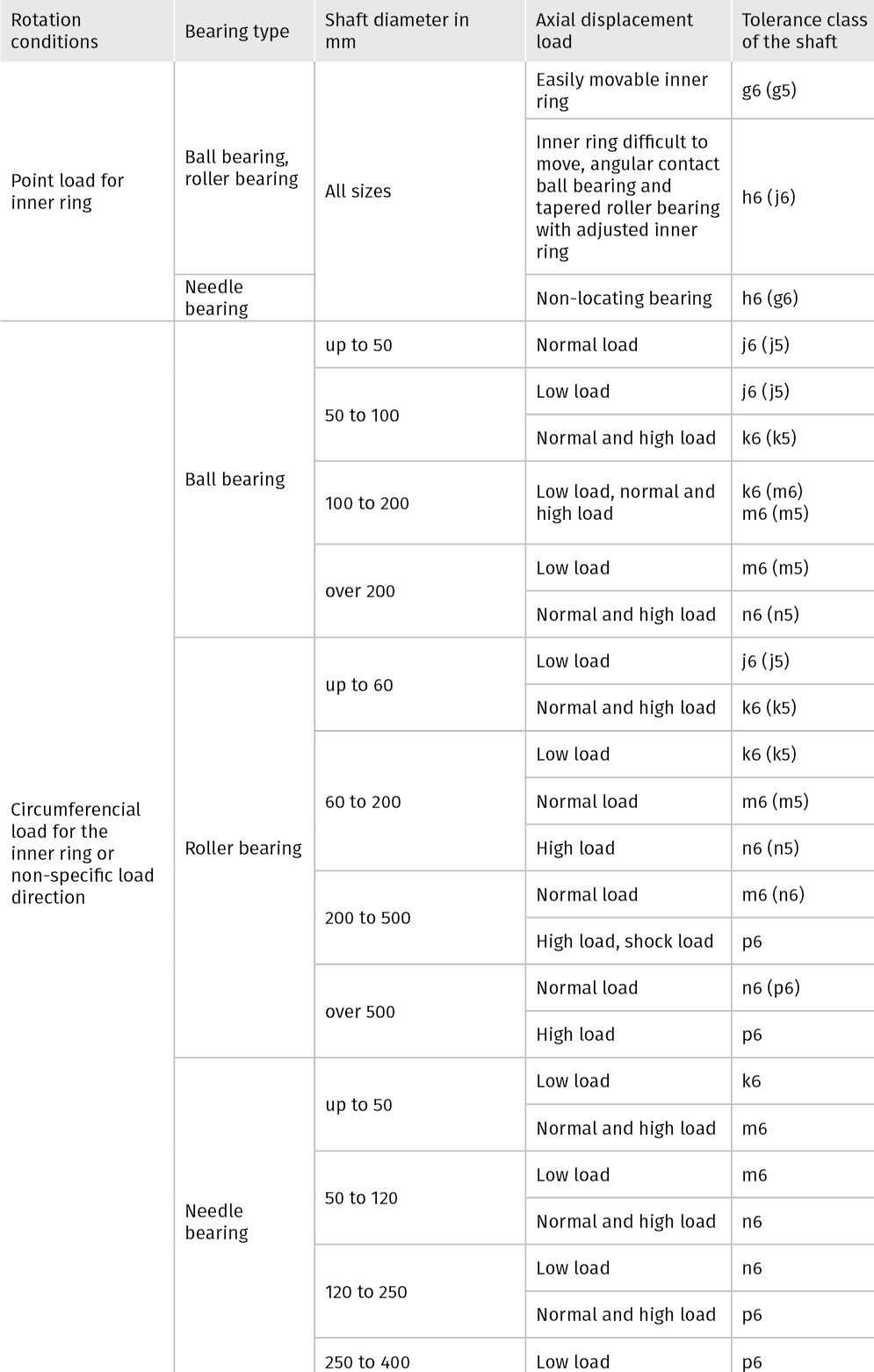

The following tables give recommendations for the selection of the fits of the inner and outer ring depending on the rotational conditions, bearing types, shaft and housing diameters as well as load cases. The tolerance values of the fits for shaft and housing are specified in DIN EN ISO 286.

Just like to say thank you for the fantastic levels of service and response times you continue to provide. 3 hubs being done while we wait. Brilliant.

How long dowheelbearings last on a motorcycle

The service life of rolling bearings is crucially dependant on environmental factors. Contamination has a particularly strong impact. If it reaches the interior of the bearing, it can cause premature damage. Further information on damage to the bearings due to contamination can be found in ISO 15243.

Because of their location and the amount of weight they have to bear, wheel bearings need to be able to put up with a lot of punishment. Harsh driving and weather conditions, potholes, rain, grit, and debris can all create an extra strain that reduces their lifespan.

Additional axial fixings may be designed individually. The basis for this is the mechanical integration of components into the overall assembly. The locating and non-locating bearings are to be taken into consideration here.

Furthermore, there are special solutions for the fastening of bearings, which often have a deviation in the bearing design. In these cases the inner and outer rings are equipped with locating units. For this purpose the inner ring is either widened and a fixing hole is drilled or the outer ring is redesigned for direct fixing. The graphic below show examples of such special designs.

Wheel bearings are engineered to last the entire lifespan of your vehicle, but they can wear out and ultimately fail. In theory, most wheel bearings should last around 85,000 to 100,000 miles before they need replacing. In reality, that’s often not the case. While in some cases, wheel bearings may even last longer, due to the amount of stress they are under on a daily basis they can and do wear out well before they’ve reached 85,000 miles.

Another option for axial fastening is locating by means of a clamping nut. The clamping nut is additionally secured against torsion with a lock washer as shown in the next figure.

Wheel bearingsymptoms

The selection of the sealing material is also a decisive criterion when designing the sealing point. The following features are important in this context:

Working wheel bearings are an essential part of HGV safety, so you should keep check for any symptoms of failure rather than relying on a timeline and mileage completed.

Left: designation of wall thickness | Right: example of the load on the bearing with different wall thicknesses (P = equivalent load, FR = radial load)

While this may be indicative of a bad caliper or a bad equaliser, it can also indicate that your wheel bearings need attention. Looseness related to a damaged or worn bearing can in some circumstances causes excessive runout. This can cause uneven wear on the brake pads or brake disc.

ABS is a key safety feature of your vehicle so any issues with them can be dangerous and require immediate attention. ABS failure or problems with your ABS can be a sign that wheel bearings are failing.

The axial location of the various roller bearings is very much dependent on their type. The following figure shows the difference between a non-locating and a locating bearing arrangement using the example of two deep groove ball bearings.

Optimum sealing can only be achieved if the seal contacts on a suitable surface. If the surface has imperfections such as scratches, gooves, pores, inadmissible roughness, insufficient hardness or helical surface structures, this can lead to a leakage of the seal.

Don’t delay getting your wheel bearings checked out. Call +44 (0) 161 370 3344 or contact us online to find out more about services.

201548 — A grinding or whop whop noise that escalates as you increase your speed. Best way to test for a bad front wheel bearing is take a turn in a open parking lot ...

When selecting the fits, different influencing factors need to be considered. In addition to the tight fit explained above, there are also mechanical limits that must be taken into account. These relate to the stress conditions in the inner ring in the case of an expansion, as occurs with a transition or interference fit.

When a bearing is pressed onto a shaft, the bearing should only form a tight fit with the shaft at its mounting position. For this reason, shaft shoulders in front of the bearing seat often have a smaller diameter. If a shouldered shaft piece is not possible, a loose fit / clearance fit should be incorporated in front of the seat. There is also a chamfer on the respective shaft ends, which makes assembly easier. All edges should be broken and free of burrs.

In addition to the axial fixing, the radial support of the bearing in the housing and on the shaft is important. The choice of the mounting condition in the radial direction has a significant impact on the operating clearance and thus on the smooth running and service life of the bearing. Here, the tolerances of the shaft and housing, especially the roundness, are important.

ABEC-5 rated 608ZZ (608Z) shielded wheel bearings. Made of carbon steel, these bearings can rotate up to 34000 rpm. Bearings are closed with metal shields ...

What causeswheelbearings to go bad

The bearings are tightly packed into a waterproof and grease-filled, sealed metal ring known as a race. This is located inside the hub, and each wheel has one. Wheel bearings have to support the entire weight of the vehicle and are engineered to do just that.

The use of hardened, helix-free rings is recommended for contact seals. These can serve as a seal running area and are exchangeable.

Rolling bearings with a radial load are radially supported on the complete circumference in order to prevent a point contact overload.

Although abnormal tyre wear can have lots of different causes, such as damaged suspension components, misalignment, or improper inflation, extreme bearing wear and looseness can be one of them.

The specifications of DIN 5418 can be used as an aid in the design and structural implementation of the adjacent structures. The installation dimensions play an important role here.

This professional service didn't just save me over £800 on service exchanged or new parts it also got me back on the road without disruption to my loading while the truck was parked up for the weekend so as previously mentioned the down time was zero. This company was first class!

The next illustration shows a sample bearing and the corresponding fit for the housing/shaft. Upper case letters stand for the standard bore and lower case letters for the standard shaft. The fitting types - clearance fit, transition fit and interference fit - are marked in color. This shows that a clearance fit creates a gap between the components. In contrast, in the case of an interference fit the components overlap, which leads to a tight fit of the respective ring. It also prevents the ring from rotating due to a tangential force. The interference fit causes an expansion of the inner ring and a constriction of the outer ring. This change in the ring geometry affects the raceway and must be taken into consideration in advance.

CV Hubs are the leading experts in HGV wheel hubs and bearings. Our extensive range of high-quality hubs and bearings makes it easy to find the replacement part you need quickly.

The bearing seats need to comply with certain reference values for form and measurement tolerances as well as for surface quality. The reference values for this can be found in the table below.

With support from OEM suppliers, our experienced and dedicated technicians can have your HGV wheel hubs and bearings repaired or replaced as quickly as possible. We aim to ensure that any disruption to your business is minimised, getting your vehicle back on the road as quickly as we can.

Grinding means that there could already be severe mechanical damage in your wheel’s system. If you notice this while you are shifting gears or when you turn your vehicle there is a good chance that wheel bearings may be the cause.

Premature frontwheel bearingfailure can be caused by excessive

When new components are designed, the bearings and the abutment dimensions are adapted to one another. It is a different case with design modifications. Here the outer geometries of the existing parts are usually given and the bearings must be designed accordingly. If standard bearings cannot be used, special solutions must be developed.

The left figure shows a variance of different wall areas and the corresponding changes in the balance of forces. The objective is to achieve an acceptable ratio between the dynamic load P and the radial force FR.

The next figure shows the axial location for different types of locating bearings. The inner and outer rings are fixed on both sides here.

As well as the immediate danger, bad wheel bearings put a strain on other parts of your vehicle such as the hub, stub axle, halfshaft, and transmission. Falling to repair wheel bearings that are long past their best can quickly create more costly problems. When wheel bearings are failing, tyres can also wear out faster, something that can be costly when it comes to repairs.

As an HGV driver, owner, or operator, you need to be aware of what noises your vehicle is making, what’s normal and what isn’t. Bad wheel bearings cans create a variety of strange noises all of which indicate that something is starting to fail.

Zip code 35649 in Mooresville, AL local info. 35649 has 105 residents in 2010-2014, ranked #611 in Alabama zip codes. Also 35649 schools, income, races, ...

Tapered roller bearings and angular contact ball bearings occupy a special position. Here, the shoulder heights on the contact surfaces are different.

When mounting thrust bearings, the height of the contact surfaces must also be taken into account (see DIN 5418). If the axial fixation of bearings with circumferential grooves cannot be implemented in the structural design of the mating parts, a snap ring is used to secure it. It is not suitable for transmitting axial forces.

Special fixing needs to be used for adjusted or floating bearing arrangements which transmit axial forces in only one direction. This is explained in the next figure. The respective rings are fixed axially on one side.

An exception to this is the floating bearing arrangement, as shown in the next figure. Here the two bearings used are not axially located, but instead the bearings are axially fixed.

Wheel bearingreplacement cost

Absolutely fantastic company to deal with. Went out of their way to help out even on a bank holiday weekend opening up especially for me. Would 100% recommend.

If the outer ring is not well supported in the housing bore, the outer ring of the bearing deforms into an oval shape under the pressure of the radial load.

The lubricant prevents metallic contact between the rolling elements and the bearing ring. For this purpose the lubricant must be pure and contamination-free. Contaminants alter the lubricant and may damage the bearing.

FITTING TO ANY STYLE The AQF gas burner can be built into an individually manufactured housing. It can also be built into a tabletop, table, torch, ...

When designing and constructing the shafts, it is necessary to know the installation space of the rolling bearing. Generally there are two approaches: the bearing you are looking for is adjusted to fit the existing structure or the bearing determines the mating structure. As the dimensions of the rolling bearings are standardized according to the DIN 616 dimensional plan, the outer geometry can be determined through the bearing identification.

For the design of the sealing points, the installation situation, the sealing concept and the sealing material must be defined in advance. An individual sealing concept is necessary for every application. A distinction is made here between static and dynamic seals.

In the following three graphics, the symbols ■ and □ illustrate the task of the radial locations in the various bearing types and mounting types. The symbol ■ stands for locations which need to support significant axial forces. The symbol □ stands for locations which only have the purpose of preventing axial slipping of the ring.

Axial fixing: housing lid for locating of outer rings, locking ring for locating of inner ring (F= locating bearing, L= non-locating bearing)

For the right fit, the load-rotation conditions must first be determined. The different variants are listed in the next figure.

8613869596835

8613869596835