10169, NY Zip Code Map - New York - 10169

Once you know what size bearing you need, you now need to establish which type and brand of bearing is best for your application. You might choose to do a like-for-like replacement, switching your bearing out for an exact replacement. However, we’d always recommend using bearing replacement as an opportunity to see if there is a bearing which is better suited to your application.

With over 15 years of technical writing and mechanical engineering experience, David Allister holds a Bachelor's degree in Mechanical Engineering from the University of Michigan. His passion for innovation and technology has made him a leading voice in industry trends, advancements, and best practices. David joined our team in 2021, bringing a wealth of experience from his time at renowned automotive companies, where he led numerous projects from planning to execution. Beyond his professional life, David is an avid cyclist and enjoys restoring vintage bicycles, showcasing his love for intricate mechanisms and sustainable transportation solutions.

The inner diameter (ID) of a bearing is also known as the bore diameter. This is the measurement of the diameter inside the bearing. To find the inner diameter of a bearing, you need to measure from one side of the inner ring to the other.

The bearing width refers to the width of the outer ring. This can be measured in the same way as the outer diameter. Simply place the jaws of your vernier caliper around the width of the outer ring of the bearing and close it until it meets the ring. Again, it should feel snug but not tight. The value which is displayed on the caliper is the width of the bearing.

Additionally, avoid high-impact loads or harsh driving conditions that could subject the bearings to excessive stress and potentially damage them prematurely.

Inevitably, these components wear out over time due to the constant stress and friction they endure, necessitating replacement.

We strive to provide high-quality, stylish home decor pieces to help you create the perfect look for your unique space. Our blog offers helpful tips and tricks to bring your dream home to life!

Often, bearings are measured in the event of a bearing failure, meaning that there is a rush to identify the bearing type and size so that a replacement can be ordered. This can lead to mistakes being made and further downtime and costs being incurred.

We will examine crucial aspects such as the vehicle’s make and model, the type and quality of replacement bearings, labor costs, and any additional components that may require replacement.

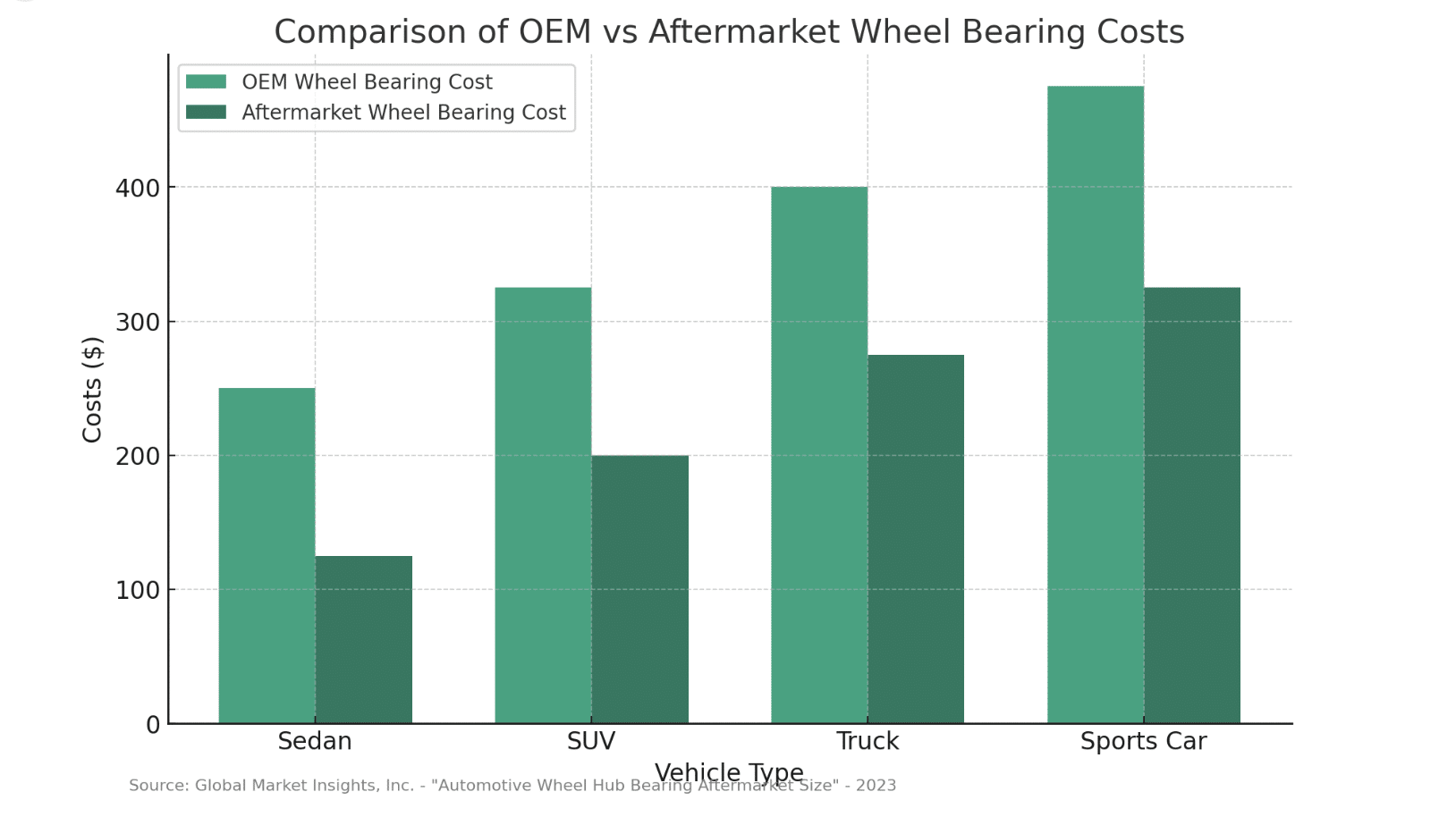

To illustrate the potential cost variations, replacing wheel bearings on a standard sedan could cost between $100 and $300 per wheel, including parts and labor. However, for a luxury SUV equipped with premium bearings, the cost could escalate to $200 to $500 per wheel, not including potential additional component replacements that may be necessary.

In some cases, additional components like wheel hubs, seals, or axle nuts may need to be replaced alongside the bearings, further increasing the overall cost.

Deep groove ballbearing

Clean the areas around the bearings regularly, protecting them from water, dirt, and debris build-up that can accelerate wear.

Providing you also know what type of bearing you have, for example an SKF deep groove ball bearing or an NSK needle bearing, you’ll be able to order a like-for-like replacement using these measurements.

If you don’t have a vernier calliper available, it is possible to measure your bearing with a good quality steel ruler, but it’s a good idea to check your measurements a couple times to ensure that they are accurate.

Older, high-mileage vehicles may require additional repairs or replacements during the bearing installation process, increasing expenses.

To measure the outer diameter of a bearing, place the jaws of your vernier caliper around the outside of the bearing and close it until it meets the outer edge of the bearing. It should be a snug fit, but not tight. Now, you can read the value on the caliper to find the outer diameter measurement.

Regular maintenance and professional inspections are essential for ensuring the safety and optimal performance of your vehicle’s wheel bearings over time.

The average wheel bearing replacement cost can vary significantly based on your vehicle’s type and the specific bearings required.

Measuring a bearing doesn’t need to be complex. We’ve put together the ultimate guide to measuring a bearing, to give you the confidence that you need to accurately measure and identify your bearings.

To measure the inner diameter of a bearing, insert the outer anvils of your vernier caliper into the bore and open the caliper until it meets the inner bore of the bearing. Now, you can read the value on the caliper to find the inner diameter measurement.

Let’s embark on this informative journey and empower you with the knowledge to navigate the dynamics of wheel bearing replacement costs confidently.

SKFbearingCalculator

One way to determine whether you have an imperial or metric bearing is to measure it. Most bearing sizes will be a full mm or inch measurement. So, if your bearing is metric, the measurement will be a full mm, for example 9mm. If your measurement is 9.5mm, it’s likely to be a 3/8 inch imperial bearing.

The most common time that you’ll need to measure a bearing is after a bearing failure. When your bearing fails, you’ll need to quickly establish the size and type of bearing before you can order its replacement.

How tomeasure a bearingMaths

This comprehensive blog aims to equip you with a thorough understanding of the factors influencing wheel bearing replacement costs.

With the right care and attention, your new bearings should provide smooth, reliable performance for years, contributing to your vehicle’s overall safety and longevity.

It’s also essential to consider the expertise and labor rates of your chosen service provider, as these can significantly impact the overall cost of the replacement process.

If you don’t have a vernier caliper, use a high-quality steel ruler to carefully measure the inner diameter of the bearing. Repeat this three times to ensure that the measurement is accurate.

NTNBearing

Like with the inner diameter, if you don’t have a vernier caliper, you can use a high-quality steel ruler to carefully measure the outer diameter of the bearing. You should repeat this three times to ensure that the measurement is accurate.

Whilst most bearings have their reference numbers laser stamped or engraved into them, these numbers often rub off over time. If you’re unable to read the reference number on the side of your bearing, you’ll need to measure the bearing to determine its size.

Once you’ve established the type and size of bearing, you can choose to order a like-for-like replacement, or to upgrade your bearings to potentially extend their service life.

Replacing worn wheel bearings is critical for maintaining your vehicle’s safety and performance on the road. Damaged or failing bearings can lead to many issues, including uneven tire wear, steering instability, and even the potential for complete wheel separation if left unchecked for an extended period.

Costs can also vary based on your geographic location and the specific service provider’s labor rates. Urban areas and dealerships often command higher prices than independent mechanics in more rural regions.

It’s essential to note that several additional factors can influence these costs, such as the vehicle’s make, model, age, and overall condition.

Not only will using the optimum bearing improve the running characteristics of your application, but it can also improve your energy efficiency and help to prevent premature

By addressing bearing issues promptly and scheduling timely replacements as needed, you can avoid more costly repairs down the line and optimize the performance of these critical components that play a vital role in your vehicle’s handling and stability.

The outer diameter (OD) of a bearing is the measurement of the total diameter of the bearing. To find the outer diameter of a bearing, you’ll need to measure from one side of the outer ring to the other.

Whether you measure your bearing in inches or millimetres will depend on whether your bearing is imperial or metric. Imperial bearings are measured in inches whilst metric bearings are measured in millimetres.

Additionally, we will emphasize the importance of timely bearing replacement and provide insightful information to help you budget effectively.

8613869596835

8613869596835