13797 Zip Code (Lisle, NY) Detailed Profile - 13797

Looking for a dynamic lubrication system that improves the productivity of your industrial machinery? Discover the many benefits and applications of DropsA’s automatic grease lubrication system. From steel plants to woodworking shops, we deliver the precise, affordable and effective lubrication your machinery needs.

How to install abearingon a shaftwithoutapress

It is important to check for proper seating of the bearing and use a special fitting tool to drive it onto the shaft. The tool should be complete with a sleeve, impact ring and dead-blow hammer.

How to installbearing into housing

The many grease lubrication systems available from DropsA North America offer particular advantages over other lubrication systems. Choose a precision centralized grease lubrication system that provides you with affordable and efficient lubrication.

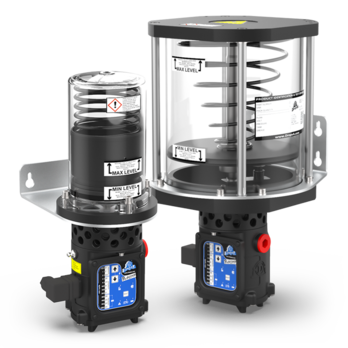

An innovative solution for small machinery, this convenient pump can still achieve an impressive 35 lubrication points while using a battery pack or main power source for flexible use.

How to install bearings on a shaftat home

Shafts with oil ducts and grooves can accept oil injected between the bearing bore and shaft surfaces, which creates a thin oil film. This reduces both the friction and the required force needed to mount the bearing. With an oil film applied, bearings can then be physically mounted using the hydraulic pump to drive them up the shaft. It achieves this by pumping oil into the hydraulic nut, which then pushes the piston out, ultimately exerting a force great enough to move the bearing into position. All the while, the pressure is being monitored by the pump for quality assurance.

At DropsA North America, we create innovative solutions that are flexible and responsive to your immediate needs. When your machinery needs routine lubrication, contact our team at 586-566-1540 to discover how you can enjoy affordable, long-lasting performance and convenient maintenance on your small or large machinery.

When engineers engineer a bearing, they calculate the life of how long it should last at a specific speed and load, and if you don’t put it on correctly, you cut that life down. “In all my years – almost 40 years now,” Zerger says, “I’ve never seen a failed bearing that’s come back, after we’ve sent it in to have it analysed, having failed because it was made wrong. It’s always the installation or lubrication issues.”

While you might not be able to see the damage, any mishandling of a bearing can end up costing you tremendously in production downtime. Even just by dropping a new bearing on the floor, Zerger says, “you don’t know the damage you could be doing. If that bearing costs $80 and it costs you $5,000 an hour for your production being down – and it takes an hour to put a new bearing in – its cheaper to throw that bearing away and install another new one.”

Bearing installation methods

Choose the grease system that offers the results you need. From large-scale paper mills to small machines of all kinds, choose among these common grease lubrication systems. While these three options are the most popular in our grease lubrication line, DropsA North America engineers customized solutions for any industrial or manufacturing need. Whether you need to include additional sensors, lubrication points or a specialized pump, we manufacture personalized systems for your large-scale or compact machinery and industrial equipment.

Bearing Installation Tool

When it comes to bearings, the quality of the overall performance, reliability and efficiency they yield, begins with the quality and precision of their installation. If there’s one thing to take away from this, it’s that nothing lasts forever and it’s up to YOU to maximize every last operational hour of your application parts.

Roller bearings play a vital role in rotating machinery by helping to: reduce friction, transmit loads and support shafts. However, 48 % of bearings fail before their natural death from being put in wrong or mishandled. Perfecting the art of bearing installation will ultimately prolong application service life and minimize downtime caused by unnecessary bearing failure.

The key here, is the temperature difference between the bearing and the shaft. Normally, a bearing temperature of about 150 F above that of the shaft is sufficient. Heating of the inner race and freezing of the outer race is the most common and recommended method. Required heat varies, though, so be sure to refer to the bearing manufacturer’s (OEM) heating guidelines.

These systems utilize a pump that separates into a progressive spool arrangement. Only a single lubrication point utilizing an UltraSensor is necessary for accurate lubrication monitoring.

For bearings with an ID that exceeds 4″/100 mm, the force needed to mount them increases considerably. This is best accomplished using heat in a process called hot mounting. The most vital factor in this method is the source of the heat. For example, techniques such as oil baths and exposure to open flames can harm and contaminate the bearings. Best results are attained using electric induction heaters, which allow for the easy regulation of heat.

Bearing mounting methods pdf

Bearing fittingon shaft

There are two types of mounting processes. Mechanical, or cold, mounting is the simpler option and is used for smaller bearings with an Internal Diameter (ID) of up to 4″/100 mm. This is often a more convenient mounting method, as the bearing can be mounted with no electricity right on the application itself.

Take special consideration to avoid applying force directly to the bearing’s: rings. cages. balls, rollers or seals. Start the bearing on the shaft with the rounder corner of the race going on first. Apply even, driving pressure, using smart, quick taps rather than heavy ones, while keeping everything square, supporting both the inner and outer race.

First, all bearings should be stored flat in a cool, clean, low-humidity environment free of dust, shocks and vibrations. In addition, there are three good habits to get into, in preparing for bearing installation, to prevent from contamination and corrosion.

Although a bit tedious, this first stage is just as vital as those that follow it. Being lackadaisical this early on in the process could threaten the bearings’ chance for survival, well before the mounting begins.

Whether you’re experiencing a faulty sensor, damaged pump or need to perform routine maintenance on a distribution block, each grease lubrication system is completely interchangeable and each part is removable for hassle-free maintenance and repair.

How to install bearings on a shaftwithouta

A lot of production falls on the accuracy of the bearings, and even though they are often made of steel, bearings are surprisingly delicate. “If you take the human hair and split it 10 times, that’s the precision that these bearings are made to have,” Tim Zerger, Bearings Business Group Director at IBT, says.

These systems require far less grease for each application than traditional use. Save time and money using a centralized system instead of manual application or other grease systems.

The key objective in mounting bearings is finding the balance between minimum required force with maximum control. Determine the best bearing installation practice for your application and arm your workforce with the technologies and tools it takes to be successful.

Once hot, carefully slide the bearing onto the shaft, and when it cools, it will grip the shaft and work efficiently. Always wear proper Personal Protective Equipment and be careful not to overheat the bearing past 250 F (or 210 F for bearings with shields or seals). Extreme heat can cause the bearing’s metallurgy to change, which can alter bearing dimensions and/or hardness.

If you need a specialized system for a unique piece of equipment, DropsA can engineer and manufacture a dedicated automatic lubrication system to achieve the production goals you set with the convenience you need.

Hydraulic mounting is recommended when dealing with extra large bearings, or tapered shafts anywhere from 2 to 37 inches in diameter. It requires less manual effort and promotes greater operator safety. Hydraulic techniques allow for greater control and precision, as well, while minimizing the risk of damage to bearings and shafts.

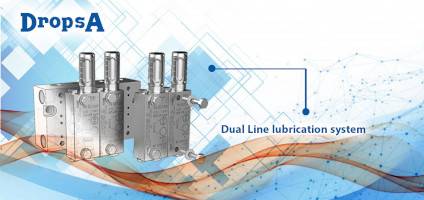

A modular system with a wide range of configurations, a Dual Line system is ideal for complex industrial equipment that requires extensive grease application stretching 60 meters or more.

IBT Industrial Solutions was founded in 1949 with Industrial Bearings in mind. Since then, we have become a trusted source for industry knowledge and expertise when it comes to bearings. When you partner with IBT, you’re guaranteed access to the best service and brands in the business.

8613869596835

8613869596835