15910 Train Route and Schedule - avadh assam exp - 15910

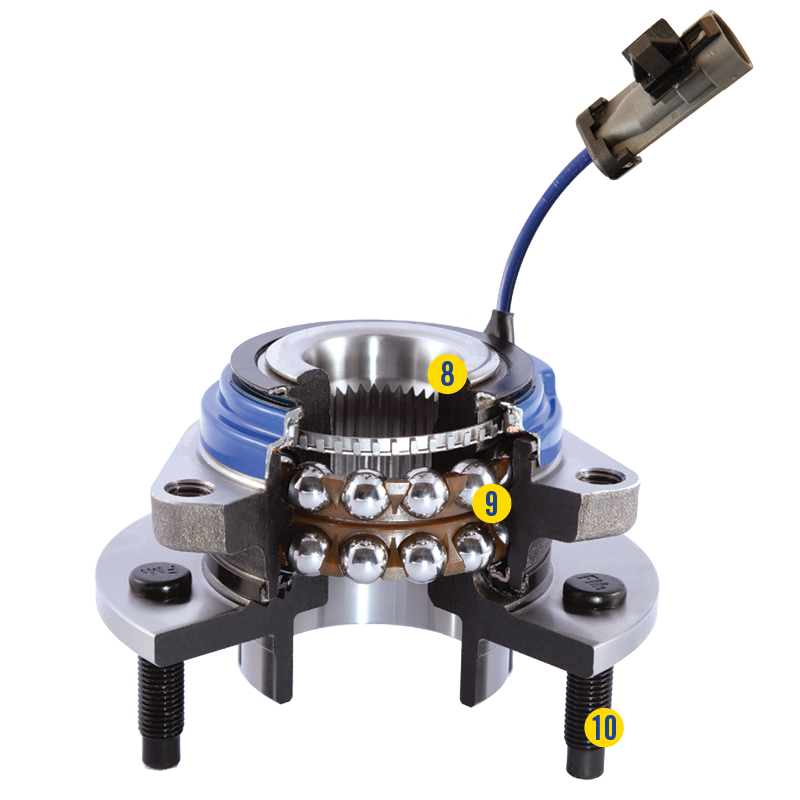

4. Grime Defense Outboard Seal helps prevent contaminant buildup on the assembly exterior, working to shield bearings from friction-and corrosion-causing moisture and grime

Roller bearing vsneedlebearing

Each type of bearing is characterized by specific properties unique to the given design and dimensions, which determine its suitability for the given type of application. Ball bearings for example are characterized by low friction and low noise. They are designed for translating medium-large radial as well as axial loads. They may be manufactured at higher precision enable them to operate at higher rpms. Due to their properties and affordability, they are among the most common types of bearings used. In contrast, spherical-roller bearings are designed for housings under high loads and are capable of compensating to a certain extent misalignments. They are thus particularly suitable for industrial use. It is thus important, when selecting the type of bearing, to consider various influences and to evaluate them according to their measure of importance for the given housing. The selection of a standard bearing is influenced particularly by:

MOOG’s commitment to continuous innovation means making existing designs even better. MOOG makes hub assemblies for a broad range of vehicles, so even older trucks can be fitted with our latest hub assembly innovations.

BallandRoller BearingCompany

Jan 11, 2016 — I clean up my bones swiss with a clean rag and add a touch of speed cream about 4 times a year. I skate on average for about 12 hours a month and they've ...

Bearings with a tapered bore (fig. 4.14) are installed on a conical or cylindrical journal using a tapered sleeve or remove tapered-sleeve adapter. The radial clearance of bearings can be set during installation. Installation and removal of bearings is relatively simple.

In certain circumstances, it presents as a limiting condition for the bearing design. In small-diameter housing, the single-row ball bearing is most often applied (fig. 4.6). Roller-contact, spherical-roller, and taper-roller bearings may optionally be used for large diameter shafts (fig. 4.7). Various types of bearings also allow for a variety of types with various bearing section strengths. Where there is limited space in the radial or axial direction, bearings with a suitable cross-section are selected (fig. 4.8).

Roller bearing vs ball bearingfriction

With regard to manufacturing inaccuracies and spindle deflections, mutual inclinations of bearing rings occur in the housing. This phenomenon should be expected and it is necessary to select bearings that compensate for the misalignment and installation inaccuracy. Self-aligning ball bearings (fig. 4.9a), two-row spherical-roller thrust bearings (fig. 4.9b), and spherical-roller thrust bearings (fig. 4.9c), are such types. The angle of inclination of such bearings depends on the type, size, and load. High rigidity bearings, such as roller-contact or ball bearings, can compensate for small misalignments, assuming that they are unburdened.

Ballandroller bearingapplication

If the load application point lies outside of the bearing axis, then an overturning torque is created. The use of a radial double-row bearing or a double-row angular-contact ball bearing usually suffices for its transfer. The use of a par of single-row angular-contact ball bearings or tapered roller bearings installed back-to-back in pairs (into an “O”), however, are preferred (fig. 4.5).

Privacy Policy | Cookie Settings | Cookie Notice | Terms & Conditions | Anti-Human Trafficking | Warranty ©2022 DRiV Incorporated. All rights reserved.

Sphericalroller bearing

2023120 — As a driver, the most common way of telling a failing bearing is a grinding noise that tends to get worse the faster you go, or the noise may ...

While the cost of the bearing drastically diminishes (usually these run between $25.00-50.00) the labor involved to replace the bearing goes up, usually to the ...

Doballbearings have line contact

Combined loads are composed of simultaneously acting radial and axial loads. Axial load capacity of a bearing depends on the angle of contact. The larger the angle, the larger the axial load bearing capacity of the bearing. Larger axial clearance in single row ball bearings increases their load bearing capacity. Single and double-row angular contact ball bearings or tapered roller bearings are best for capturing combined loads (fig. 4.3a). Combined loads can also be borne by double-row spherical-roller bearings, thrust ball angular-contact bearings, and to a limited extent, also spherical-roller thrust bearings. Self-aligning ball bearings, NJ, NUP, or NJ roller-contact bearings and NU bearings with HJ attachment rings (fig. 4.3b) can be used for combined loads with a relatively small axial component.

Hub assemblies are critical for safe and reliable operation of a vehicle — and they're subject to some of the harshest punishments the road can dish out. High temperatures, extreme stresses, water and contaminants can take a toll on hub assemblies that aren't up to the challenge. That's why MOOG engineers continually introduce purpose-specific innovations that stand strong against harsh conditions — and make MOOG hub assemblies durable and reliable for years of hassle-free operation.

Product Matches (16 results - showing page 1 of 1). 65040 · Brighton Best All Thread · All Thread Rod - Steel. Nuts | Bolts | Screws All Thread Rod - Steel.

May 14, 2022 — ... 53.975 × 5.08 cm). Acrylic on canvas. Katherine Bradford,. Night Swimmer and Lifeguard,. 2022,. 21 ¼ × 17 ¼ × 2 inches (53.98 × 43.82 × 5.08 cm).

A fixed axial and free axial bearing is general used for supporting shafts, while the fixed axial bearing provides shaft guidance in both directions and the free axial bearing compensation for the axial change in length and thermal expansion. If axial displacement of thermally expanding components is prevented, then uncontrolled axial overloading of firmly fixed bearings may result. Bearings that can carry combined loads are most suitable for capturing axial forces. Bearings that are best able to afford axial movement are NU and N roller-contact bearings (fig. 4.10). If ball or roller-contact bearings are used as free bearings, then one of the bearing rings (usually the outer) must be attached freely (fig. 4.11).

Taperedroller bearing

50:1 Ram air motor grease pump, cover, follower, control handle, z-swivel, carry handle, and 7′ dispense hose for 35 lb pail.

In addition to thrust bearings, ball bearings or four-point ball bearings can be used for capturing axial forces (fig. 4.4).

9. Increased Ball Size, Advanced Raceway Design, and Precision Matched Components for lower friction, increased load capacity and longer service life

Ball bearing vs roller bearingapplication

202467 — This unit has been equipped with a chrome steel locking collar insert ball bearing which uses a machined locking collar with two set screws to ...

Choose from our selection of spanner nut socket sets, including spanner sockets, wheel bearing locknut socket sets, and more. In stock and ready to ship.

Fluid Evacuators. Fluid Evacuators | Mityvac MV6400 Fluid Dispensing System image number 0. pdp share icon Share.

Get directions, store hours, and print deals at FedEx Office on 595 W 49th St, Hialeah, FL, 33012. shipping boxes and office supplies available.

These bearings are more easily installed and removed, if they can be taken apart. This particularly applies for bearings within a fixed housing. Separable bearings are also suitable for use where frequent installation and removal are required. A ring with roller-contact elements may be installed separately, irrespective of the second ring (fig. 4.13a – 4.13c).

ZKL Company provides a full range of unilaterally or bilaterally packed or encased roller-contact bearings. The bearings use contact (friction) packing (fig. 4.15) or are encased (fig. 4.16) using non-contact (touch-less) packing. Bearings with dual-side packaging are filled with plastic grease and do not require additional greasing during operation. The use of such bearings makes it possible to design economical and spatially undemanding housing. In other instances, care must be taken to monitor the structure of other components to prevent unwanted leaking of grease and entry of contaminants into the bearings.

8613869596835

8613869596835