18603 Train Route and Schedule - RNC GODA EXP - 18603

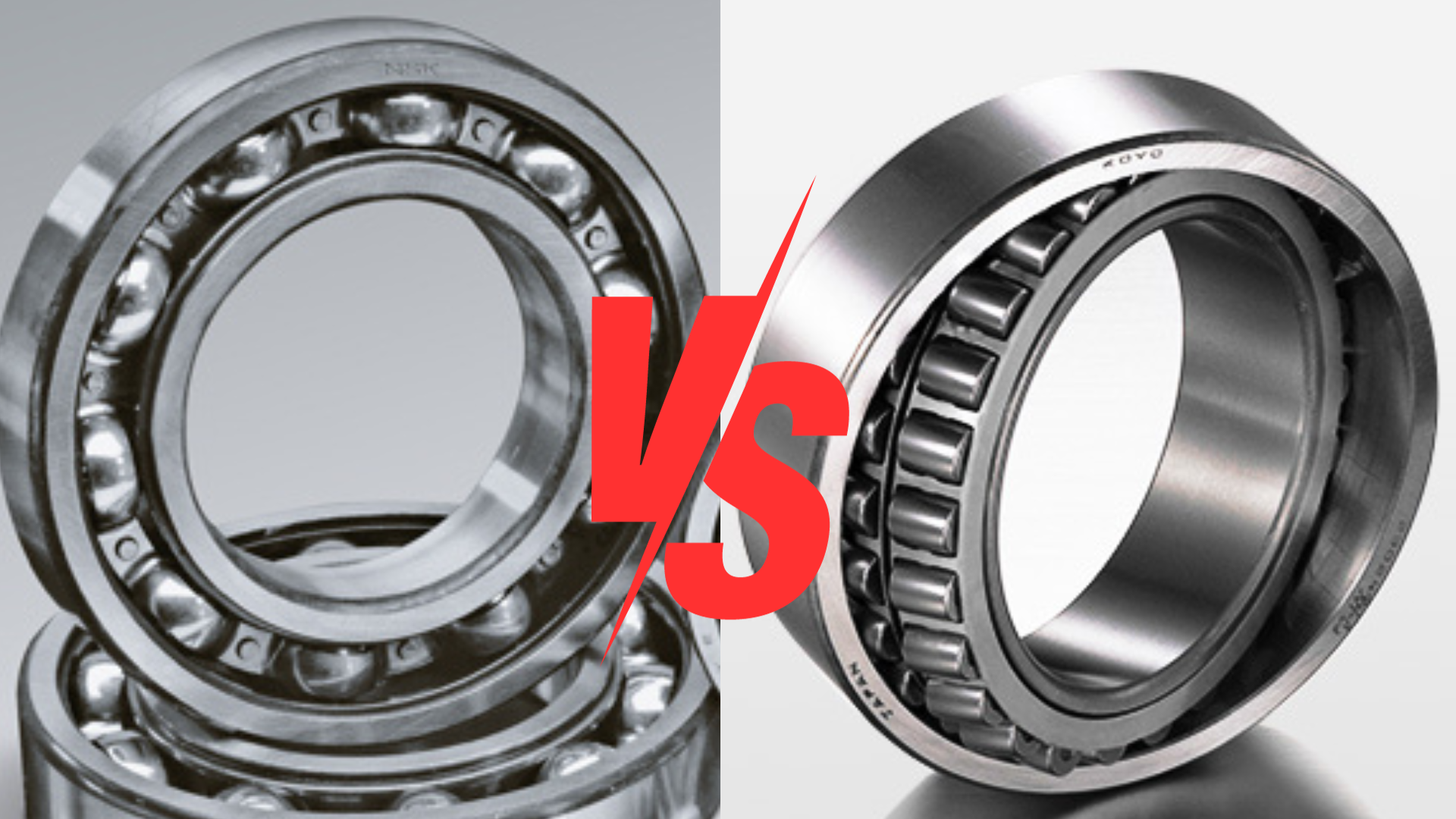

The older style cone shaped bearings have a series of tapered rollers in a cage with a window for each roller to keep them evenly spaced while they ride between inner and outer races. But most modern sealed bearings have steel balls with inside and outside races.

A faulty wheel hub and bearing assembly can also cause a vibration felt in the steering wheel. Often, the sensation will change with vehicle speed or while the vehicle is cornering.

Roller bearings come in various configurations, including cylindrical roller bearings, tapered roller bearings, spherical roller bearings, and needle roller bearings, among others.

Printing Presses: Printing presses involve high pressure and continuous operation, making roller bearings a suitable choice to handle substantial radial loads.

Thank for pointing out that typo. The paragraph was supposed to read: Some front-wheel drive vehicles have wheel bearings of this type on the rear. We have updated the article.

Roller bearings use cylindrical, tapered, or spherical rollers as their rolling elements. The rollers offer a larger contact area, distributing the load over a larger surface compared to balls. They also come in various designs, such as cylindrical roller, tapered roller, and spherical roller bearings.

A faulty wheel bearing can cause your vehicle to pull to one side during braking. This symptom can also be related to faulty brake components.

Roller bearings are indispensable mechanical components widely used in automotive and aerospace industries for heavy machinery and manufacturing. These bearings are designed to support radial or axial loads in low friction, making them essential for smooth and precise motion.

Note by Richard McCuistian, ASE-certified mechanic: I have personally seen a Crown Victoria that was making a noise I would have sworn was coming from the left rear axle bearing, but after removing and inspecting that bearing (which is difficult on a rear wheel drive vehicle), I discovered that the noise was actually originating from the left front tire. And I had nearly 40 years of automotive experience at the time.

Mounting Surfaces: The outer ring may have mounting surfaces or flanges that can be plain or threaded, depending on the specific application requirements.

Roller bearings and ball bearings are fundamental components in various mechanical systems, serving the critical role of reducing friction and facilitating smooth motion. These two types of bearings differ significantly in their design and applications.

I have personally seen a Crown Victoria that was making a noise I would have sworn was coming from the left rear axle bearing, but after removing and inspecting that bearing (which is difficult on a rear wheel drive vehicle), I discovered that the noise was actually originating from the left front tire. And I had nearly 40 years of automotive experience at the time.

Inner Ring (Inner Race): The inner ring, also known as the inner race, is a ring-shaped component that fits directly onto the rotating shaft or axle. It provides a smooth and precise surface for the rollers to roll against.

Aerospace Applications: Aircraft engines, landing gear systems, and other aerospace components often use ball bearings to reduce weight and minimise friction.

Wheel bearing noisewhen driving

By now, you may have an idea of how important wheel bearings are. Thankfully, there are signs that can indicate that your wheel bearings are going bad.

Bicycles: Ball bearings are commonly used in bicycle hubs where low friction and high-speed rotation are critical for efficiency and reduced pedalling effort.

This paragraph doesn’t make sense: Older rear wheel drive vehicles had cone type wheel bearings on the front wheels that could be removed, inspected, and packed with grease, and reinstalled with new seals. Some rear wheel drive vehicles have wheel bearings of this type on the rear. In other words, if a vehicle has cone-type bearings that can be removed, inspected, and repacked, it will always be on the NON-driving wheels – the ones that don’t propel the vehicle.

Some may say that you can drive for up to a thousand miles with a failed wheel bearing—but the thing is, this is an arbitrary claim. There’s really no telling how long you can safely drive your vehicle in this state. It would depend on the severity of the damage to your wheel bearing, present road conditions, and other factors. So, it’s best not to push your luck.

Deep Groove Ball Bearings: They have deep raceway grooves and are often used in electric motors, household appliances, and automotive components.

Understanding these distinctions is crucial for selecting the right bearing to optimise performance and longevity in various industrial and mechanical systems.

Cage (Retainer): While the linear guide has its carriages, the ball bearing has a component called cage, or retainer, which prevents the balls from coming into contact with one another and maintains their even distribution around the raceway.

Ball bearings are well-suited for high-speed applications due to their low friction and smaller contact area. Ball bearings are more forgiving of misalignment compared to roller bearings.

Wheel bearingreplacement cost

Ball bearings are ideal for applications requiring high rotational speeds, as opposed to roller bearings which are more suitable for slow-speed applications. Ball bearings also produce less heat during operation, and can better accommodate slight misalignment.

Remember, the wheel bearing not only allows the wheel/tire assembly to rotate along with the hub the wheel is bolted to, the bearing also carries the weight of the vehicle and maintains the spinning wheel’s axis by keeping it in a straight line. A failed wheel bearing won’t usually allow the wheel to come off completely unless the bearing has become so hot that the axle or spindle is glowing red. Not only can this cause a fire in the wheel well area, the wheel and hub can separate from the vehicle and… well, finish the thought. Granted, this is a very extreme case of a wheel bearing failure, but wheel bearings that have lost their grease can get extremely hot.

Wheel bearing noise coincides with the rotation of the tires. The sound typically increases with vehicle speed as well. In some instances, the noise may also change when you turn the steering wheel in one direction or the other.

20131113 — 12360——12360

Is your ABS light on, and you do not know what is causing it? A faulty wheel bearing can be a possibility. On some vehicles, the ABS sensor or encoder ring is integrated into the wheel hub and bearing assembly. As such, a failure of the wheel bearing can trigger the ABS light.

If the seal that is part of the bearing fails, moisture and dirt can enter the bearing’s grease, compromising the grease’s ability to keep the load bearing elements (balls and races) lubricated. But there are times when a bearing destroys itself even though the grease is not compromised. Tiny particles of metal can begin to flake off of the races, and when this happens, those particles mix with the grease so that it becomes a grinding compound of sorts, creating a “snowball” effect whereby more metal flakes off and enters the grease charge and the bearing gets noisier with time.

Mechanics will find a safe, empty, smooth paved road, then listen carefully to the noise while swerving gently from side to side – typically when you swerve to the right, you’re increasing the load on the left side bearings, and vice versa. And again, while this is a good practice, it’s easy to be fooled into replacing the wrong bearing, even using this method – that’s why some tire shops replace bearings in pairs. If you use this method and believe the noise is tire related, you can move the front tires to the rear and see if the noise changes.

Roller bearings generally have a higher load-carrying capacity, making them suitable for heavy radial and axial loads. They can better absorb shock and vibration due to their larger contact area and may require more precise alignment due to their sensitivity to misalignment.

Let's explore the fundamental principles and types of ball bearings that highlight their significant role in modern engineering and technology.

Pro Tips are nuggets of information direct from ASE-certified automobile technicians working with CarParts.com, which may include unique, personal insights based on their years of experience working in the automotive industry. These can help you make more informed decisions about your car.

Cage (Retainer): The cage, often called the retainer, holds the rollers in their proper positions and prevents them from contacting each other. It ensures that the rollers are evenly spaced within the bearing.

Wheel bearing noisedangerous

It’s this abnormal sound that’s the most obvious sign something is wrong with your wheel bearings. Of course, because other issues, such as cupped tires, can mimic a bad wheel bearing, you’ll want to diagnose the sound properly.

If your wheel bearing goes out while you’re on the road, it’s not advisable to keep driving. However, if there’s absolutely no alternative, make sure to maintain a slow and steady pace—do not accelerate or turn suddenly.

The design of the tapered roller bearings allow them to carry simultaneous radial and axial loads. The axial load carrying capacity of tapered roller bearings ...

Conveyors: Conveyor systems that carry heavy loads benefit from roller bearings, ensuring smooth movement even under significant weight.

Wheel bearings support the weight of the vehicle and allow the wheel/tire assembly to rotate when you’re traveling down the road. All four of your car’s wheels have wheel bearings and they are designed to last the life of the vehicle. In fact, many vehicles will travel hundreds of thousands of miles/kilometers and never need a wheel bearing replacement, but others may need one or more wheel bearings replaced over their lifetime.

The CarParts.com Research Team is composed of experienced automotive and tech writers working with (ASE)-certified automobile technicians and automotive journalists to bring up-to-date, helpful information to car owners in the US. Guided by CarParts.com's thorough editorial process, our team strives to produce guides and resources DIYers and casual car owners can trust.

Since the wheel bearings keep the wheel and hub assembly spinning on an axis, if the wheel bearing is compromised to the point that it can no longer maintain that axis, driving with a faulty bearing can be extremely dangerous—especially at high speeds. Think about a wheel that starts wobbling because the bearing decided to completely come apart while you’re in freeway traffic. This can happen without warning if you’ve become accustomed to the bearing’s noise as it continues to warn you by getting louder.

Badwheel bearingsymptoms

Roller bearings excel in applications with heavy radial and axial loads, such as in conveyor systems and large industrial machinery. They are also preferred for heavy loads over other types of bearings, due to their larger contact area and enhanced rigidity. Roller bearings tend to have higher rigidity, which means they are better at resisting deformation under heavy loads.

Another tricky element of wheel bearing noise is the need to pinpoint which wheel bearing is making the noise. Sometimes even professional mechanics will struggle with this, and there are special listening devices shops use to pinpoint which bearing is making the noise. Some tire shops will replace both front bearings if there is a bearing noise coming from the front of the vehicle; not a bad practice, actually.

Loose wheel bearings can throw your car’s alignment off, leading to abnormal tire wear. There are, of course, many other problems that can create the same, undesirable results. So, you’ll want to diagnose the issue thoroughly before condemning one or more of the wheel bearings

FACTORY AUTHORIZED PART BENEFITS • Meets exact part design life testing for maximum reliability and durability. • Provides exact drop-in replacement.

Outer Ring (Outer Race): The outer ring, encases the inner components of the bearing and provides a stable housing for the rollers. It typically has a groove or track for the rollers to run along.

Olio lubrificante in quantità minime per la lubrificazione degli utensili del centro di lavorazione Perforex BC, del Perforex MT e del centro laser Perforex ...

Inner Ring (Inner Race): The inner ring, or inner race, is positioned inside the outer ring and fits onto the shaft or axle.

One tricky thing about wheel bearing noise is that a bad tire can make almost exactly the same noise as a bad bearing; you don’t want to replace a wheel bearing for a noise concern when all you need is a new tire.

Mounting Surfaces: The outer ring of the bearing often includes mounting surfaces or flanges, which facilitate the attachment of the bearing to a housing or support structure.

Also, by replacing a bad bearing early on, you can also save yourself a lot of money by avoiding possible major repairs.

There are different kinds of wheel bearings depending on the year model and the design of the vehicle. Older rear wheel drive vehicles had cone type wheel bearings on the front wheels that could be removed, inspected, and packed with grease, and reinstalled with new seals. Some front-wheel drive vehicles have wheel bearings of this type on the rear. In other words, if a vehicle has cone-type bearings that can be removed, inspected, and repacked, it will always be on the NON-driving wheels – the ones that don’t propel the vehicle. Trailer wheels often have bearings of this type.

Angular Contact Ball Bearings: Designed with angular contact points between the balls and the raceways, they come in various configurations, including single-row, double-row, and four-point contact.

Good Quality 4T-CRI-0760 35X64X37mm Double Row Taper Roller Bearing for Automotive Wheel Hub Bearing 4T-CRI-0760 35X64X37mm From China - ZhongHong bearing ...

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication. Read our full disclaimer here.

Automotive Axles: In the rear axles of trucks and some high-performance cars, roller bearings are preferred for their capacity to handle both radial and axial loads, ensuring stable and safe driving.

In cases like that, or when you just decide to keep driving until the failure is complete, the bearing itself will decide for you when it must be changed, and it can do so in very unpleasant ways and never at a good time. In other words, there are instances, when left unattended to, a faulty wheel bearing can create hazardous conditions, such as the following:

A bad wheel bearing can cause the brake rotor to wobble, which shoves the caliper piston back into its bore so that when you apply the brakes, you have unexpected pedal travel as a result – making it harder to stop or causing the vehicle to pull unexpectedly to one side – never a good thing in traffic.

The key feature that sets roller bearings apart is their use of cylindrical rollers or sometimes tapered and spherical rollers, which distribute the load more evenly than ball bearings. This introduction will provide an overview as well as explore the types of roller bearings.

Wheel bearing failure is a potentially dangerous situation at any time, so have your vehicle towed to the nearest mechanic and have your faulty wheel bearings replaced right away. Vehicle safety should always come first.

Clearance and Preload: Clearance refers to the internal gap between the rolling elements and the rings, while preload is a deliberate axial load applied to eliminate clearance and enhance the bearing's stiffness.

Precision is the key to minimizing friction in transmission, and bearing lubrication is the answer to ensuring the rolling component keeps on rolling. ...

Seals and Shields: Some ball bearings incorporate seals or shields to protect the internal components from contamination, such as dust, dirt, or moisture.

When it comes to Needle Roller Thrust Bearings & Washers, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, ...

Balls: Ball bearings get their name from these small, precisely manufactured spherical rolling elements. The number and size of balls may vary based on the bearing's design and intended purpose.

Frontwheel bearing noisesymptoms

At SLS Bearings, our decades of experience have enabled our deep understanding of the unique challenges faced by our customers. Our quality products offer the best solutions for your roller bearing needs.

Electric Motors: Electric motors, including those in household appliances, benefit from ball bearings due to their ability to operate at high speeds with minimal friction and heat generation.

Modern vehicles have sealed wheel bearings that cannot be disassembled without destroying the wheel bearing assembly in the process, and on vehicles with bearings like those, you only know a bearing is bad when it begins to make noise. That’s the earliest indication of a bad wheel bearing, and front wheel bearings (both on front wheel drive as well as rear wheel drive vehicles) are the most prone to fail on modern vehicles.

Are you visiting SLS Bearings from outside the Singapore? Visit your regional site for more relevant language.

Your choice of roller bearing heavily depends on your machine requirements, such as load capacity, speed, precision, and environmental conditions. Choosing the right roller bearings is important to ensure their long-term reliability and to avoid common issues such as premature failures.

It’s worth noting that tire noise will usually change depending on the road surface. Wheel bearing noise, on the other hand, is consistent regardless of road surface and acceleration.

Self-Aligning Ball Bearings: These types of bearings are made with two rows of balls which makes them suitable for reducing misalignment and shaft deflection.Insert Ball Bearings: These are designed to be easily inserted into housings and are commonly used in applications like agricultural equipment, conveyor systems, and mounted units.

Buy Tecumseh 28540 Oil Seal Genuine Original Equipment Manufacturer (OEM) part: Seals - Amazon.com ✓ FREE DELIVERY possible on eligible purchases.

Hydraulics may be one of the most important inventions in the modern world. They are used in a variety of ways, impacting everything we do in our life ...

Once again, there are other issues besides a bad wheel bearing that can cause steering wheel vibrations. A thorough diagnosis is needed to verify the cause of the concern.

Badwheel bearinghummingnoise

Wheel bearings are in a hostile environment and are working very hard, but wheel bearings are very tough – they’re designed for the work they do. But product variability is a real thing, and again, some bearings fail while others never do.

Ball bearings employ small spherical balls as their rolling elements and have a point contact with the raceways, resulting in a smaller contact area and higher point loads. Common types include deep groove, angular contact, thrust, and self-aligning ball bearings.

Thrust Ball Bearings: These bearings consist of two grooved washers with balls between them. They are commonly used in applications where axial load capacity is essential.

O'Reilly Auto Parts carries hub assemblies or wheel bearings for most vehicles to help make your repair and keep you on the road safely.

In the event that this happens under weather conditions that make the road slippery, immediately maneuver your vehicle to the nearest safe spot off the road.

Wheel bearingknockingnoise

Equipment that requires frictionless power transmission needs a specially chosen bearing that is able to handle its operations environment. The bearin ...

The wheel bearing on a wheel usually consists of a pair bearing assemblies running side by side on the shaft or spindle – this keeps the spindle running straight, while a single row of balls or rollers might allow the wheel to wobble. Exceptions would be the non-tapered roller bearings on rear wheel drive vehicles, which will have only one bearing assembly at the wheel end of the axle, but the inboard end of the axle on those units is splined to the differential assembly, which is spinning in its own set of tapered roller bearings.

Pro Tip: If a noise happens after the tires are rotated on a front wheel drive vehicle, it may be due to the wear pattern on the tires, so be aware of that, too.

Ball bearings come in various types, each designed to meet specific application requirements. Here are some of the most common types of ball bearings:

A worn-out wheel bearing may also make a high-pitched squealing sound while you’re driving. If you are able to observe these symptoms, have your vehicle checked right away. Even if your wheel bearings are not the culprit—there’s definitely something wrong with your vehicle.

Wheel bearing noisequick fix

Washing Machine: The electric motor that powers the washing machine also contains ball bearings. These bearings support the motor's rotating shaft, reducing friction and ensuring that the motor operates efficiently.

In conclusion, the choice between roller bearings and ball bearings is not a matter of one-size-fits-all but a deliberate selection tailored to the unique needs of the given application. By understanding their strengths and limitations, engineers can ensure the seamless operation of mechanical systems and the promise of maximum performance.

This article delves into the world of AliExpress, where you can find a diverse array of plastic ball pit balls, comparing features, benefits, and tips on how to ...

Richard McCuistian has worked for nearly 50 years in the automotive field as a professional technician, an instructor, and a freelance automotive writer for Motor Age, ACtion magazine, Power Stroke Registry, and others. Richard is ASE certified for more than 30 years in 10 categories, including L1 Advanced Engine Performance and Light Vehicle Diesel.

This study delves into the comparison in design, functionality and performance to help you determine which bearing has the best features suited for your engineering needs.

Can your car still run with a faulty bearing? The technical answer might be yes; some wheel bearings might continue to operate normally despite the vehicle being driven with one or more noisy bearings for a very long time. The problem is that since the noise begins gradually and slowly gets worse, you might not even notice the noise if your vehicle is noisy in other ways.

Available in several variants and designs, providing excellent performance under hot or dry conditions and at low operational speeds. Long service life and ...

Heavy Machinery: Roller bearings are commonly used in heavy machinery like construction equipment, cranes, and mining machinery.

You might have seen a vehicle pulling trailer that has had the bearings neglected to the point that the wheel gets hot enough to set the tire on fire – it can happen on your vehicle in extreme cases, but it’s rare.

When you’re driving with the music cranked up, you may not notice the different sounds that your vehicle makes. But the moment you turn the radio off and notice a growling, humming, or rumbling noise coming from your wheel bearing, you’ll know there’s a problem.

Ball bearings are integral mechanical components with an ingenious design that employs small spherical rolling elements, often referred to as balls. Ball bearings are renowned for their versatility, exceptional durability, and high precision.

Seals and Shields: Seals are typically used for applications where protection is essential, while shields provide less protection but lower friction for the roller bearings.

8613869596835

8613869596835