2006 Nissan Altima Wheel Bearing Replacement Prices & ... - 2006 nissan altima wheel bearing

Zinc ii bromide formula

Radial Bearing, Shield, 1.0000 in. Bore: Deep Groove Ball Bearings: Amazon.com: Industrial & Scientific.

2010126 — ... Sil ... Eighty Front half of a Silvia Back half of a 180SX There's ... 'Sil'via + 1'80'SX = Sil80 aka Sileighty (unofficial car, never ...

Znbruses

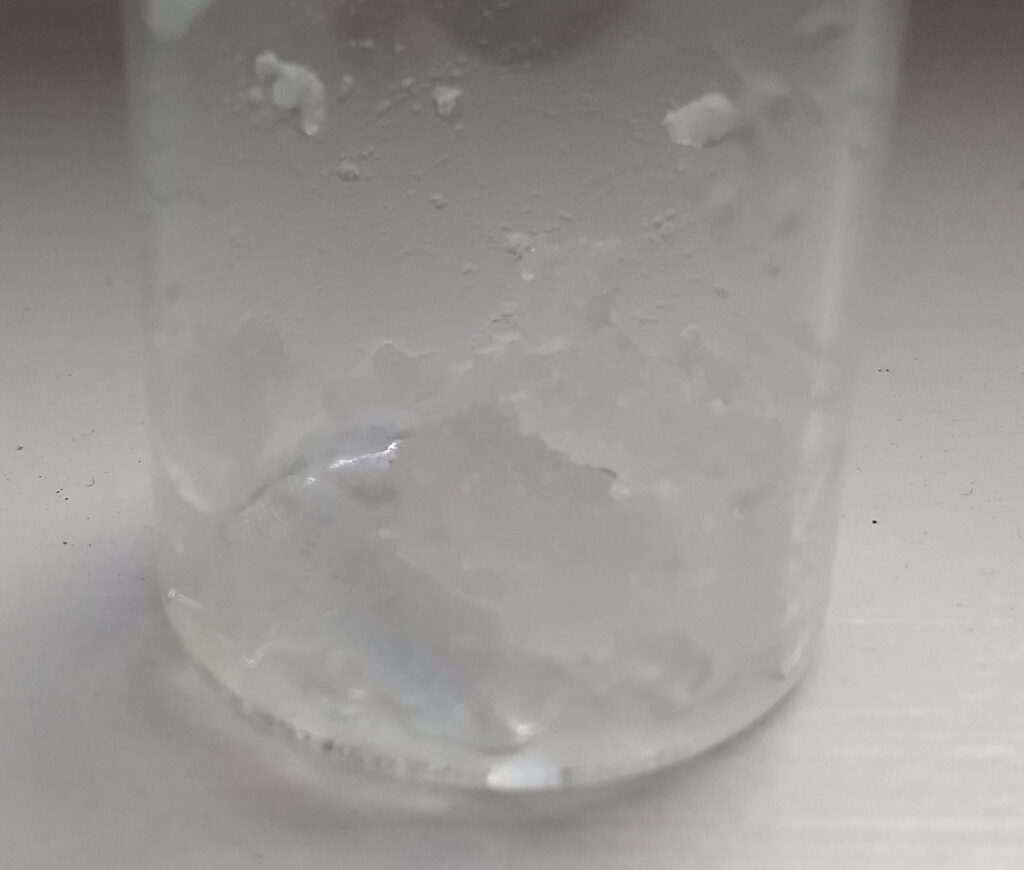

It is worth noting that they are aware of the above facts. You can see this in the image above – taken from the supporting information of the paper – where they clearly show TBABr forms an insoluble perbromide. So why did they choose to go with a significantly more expensive chemical (TPABr) and not use TBABr when its the obvious choice from a practical standpoint?

However, since this is a mostly ZnBr2 containing solution – with likely less than 5% of the salt weight being from sodium sulfate contamination – we can estimate the amount of Zinc Bromide by measuring the density of the solution and looking at experimental results showing the density variations of pure Zinc Bromide solutions. Using the experimental data from this paper from 1994, I was able to create the above graph, which allows you estimate how concentrated your Zinc Bromide solution is. Note that you should input the density in the equation expressed in kg/m^3.

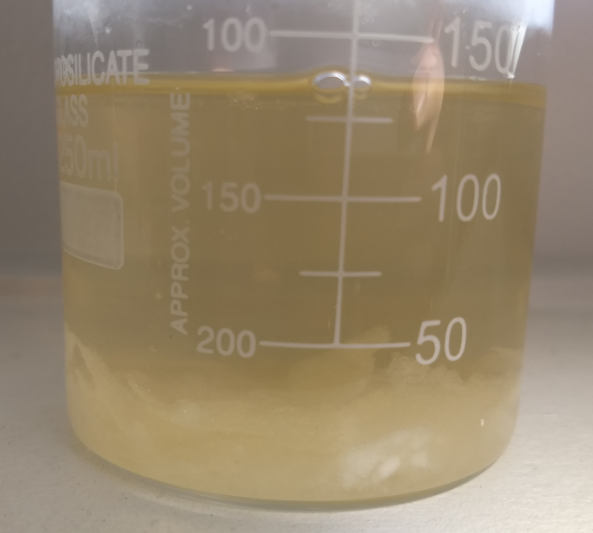

The image above shows you how this reaction looks. The Fe compound generated is very red, while the precipitated sodium sulfate is white, giving you this sort of look. The reaction takes around 6 hours to fully complete – for all the Fe to be precipitated out – time after which you can filter the solution and measure the density of your resulting brine to figure out what approximate concentration you have (per my previous post). It’s crazy how much Iron the “high purity” agricultural grade Zinc Sulfate Monohydrate contains!

The cheapest solution I have found comes from the use of readily available Zinc Sulfate and Sodium Bromide. Both of these salts are available in high purity at very low retail prices (<10 USD/kg even when buying sub kilogram quantities). Since Sodium Sulfate is significantly less soluble than Zinc Bromide, preparing a very concentrated solution containing both salts leads to the precipitation of Sodium Sulfate with Zinc Bromide remaining in solution. The problem with this approach is that the solution always contains a substantial amount of Sodium Sulfate and the many separation/concentration/crystallization steps involved to obtain higher purity ZnBr2 make it a rather impractical approach if higher purity Zinc Bromide is required or if you want to achieve the result quickly.

Znbr2 name

Secondary Zn-Br batteries suffer from a huge problem of self-discharge due to the formation of elemental Bromine which, although largely insoluble in water, is soluble enough to migrate through the cell and react with the zinc anode, effectively self-discharging the cell.

I haven’t scaled this process up – as I only work at very small scales – so I don’t know what problems could occur at larger scales. Since it involves alcohol I would advice working at a small scale to see if this process might fit your needs and to be careful and follow all safety precautions.

As I mentioned on a previous post, a better sequestering agent must allow for large solubility, be commercially available and form an insoluble perbromide. The only candidate I can think of to fulfill this role would be trimethylphenylammonium bromide (TMPhABr). I might be tempted enough to test it to order some from Alibaba if I can get a low quantity order for a reasonable price!

The graph above shows the first – to the best of my knowledge, the first ever public – charge/discharge curves of a static Zn-Br cell prepared using TMPhABr as a sequestering agent. It is very interesting to note that the shape of the discharge curve improved immensely moving from TBABr, showing that this battery is significantly better behaved. Although the CE and EE of this first curve were particularly low, the CE of the second curve measured already showed an increase of the CE to 79% and EE 66%. I will keep cycling the battery and will show you how the CE and EE change as a function of the number of cycles. Exciting times!

The above described process – using rubbing alcohol – has the advantage of producing the Zinc Bromide quickly, without the need to perform successive steps of cooling/decanting/filtering/crystallizing, etc. Since both Sodium Sulfate and Zinc Sulfate are almost completely insoluble in alcohol containing solutions – while Zinc Bromide is not – this leads to a significantly faster and more satisfactory synthesis from readily available chemicals. Using a slight excess of zinc sulfate is recommended to avoid the presence of Sodium Bromide in the final solution.

Znbrpowder

MISUMI Ball Bearings - Grease Filled, Heat Resistant Up To 230Deg.C offers exceptional reliability by maintaining optimal lubrication in high-temperature ...

To circumvent this issue, researchers have used chemicals that sequester the produced bromine into a product that has even less affinity for water — an insoluble or immiscible perbromide. In flow batteries this is done to generate a liquid phase that is immiscible with water, since it still needs to be a liquid to allow proper flow of the reagent. In static batteries this is undesirable, because a liquid is still able to flow through the cell and react with the Zn anode.

An important issue with Zinc-Bromine batteries is the need for a high purity Zinc Bromide solution in order for the battery to work properly. The use of low-cost ZnBr2 sources, in particular the use of Zinc Sulfate and Sodium Bromide to generate Zinc Bromide solutions, can be problematic due to the presence of large amounts of Iron impurities. In this post I will discuss what happens when you have these impurities in a battery and how you can purify a Zinc Bromide solution to remove iron and achieve better results.

In order to measure the density of the solution, I used a 10mL pycnometer, which you can buy here for a low price. A pycnometer allows you to very accurately determine the density of a solution since its volume is exact. By weighting the empty pycnometer and the filled pycnometer and then dividing the difference of this weights by 10 (volume of the pycnometer), you can obtain the measurement in g/mL which you can multiply by 1000 to get the value in kg/m^3.

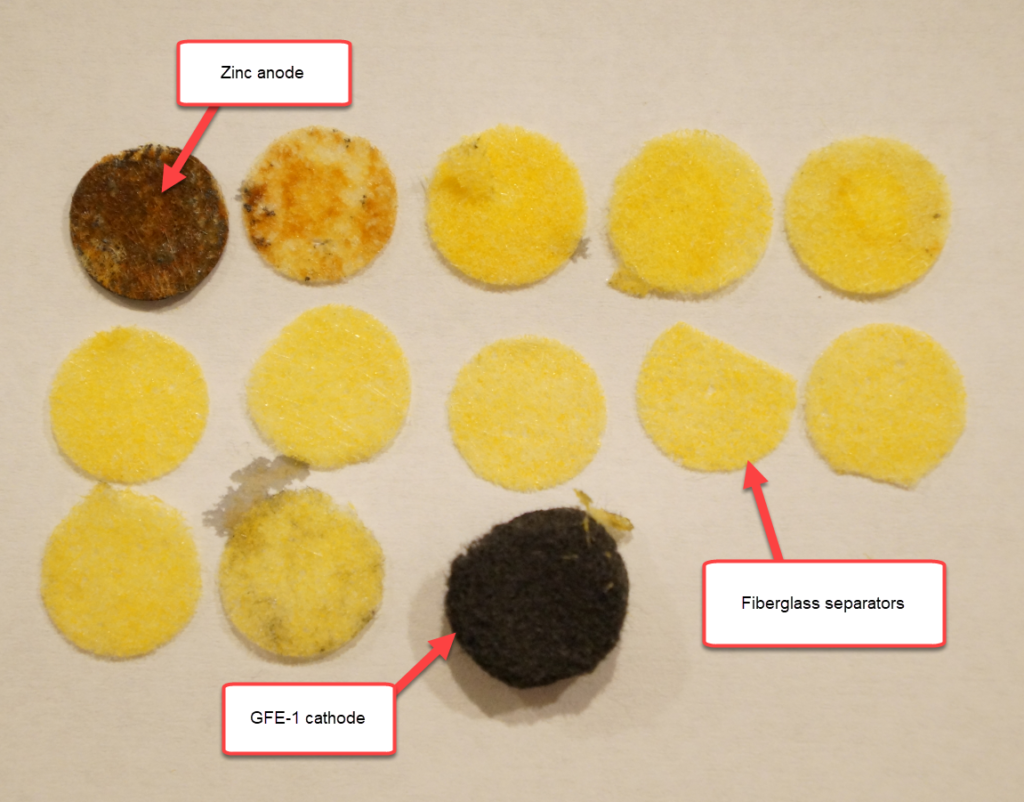

I then used this 0.5M ZnBr2 + 0.25M TMPhABr solution to create the first battery. This battery had a diameter of 0.5 inches and was built within my Swagelok cell. I used a 0.2mm thick Zinc anode followed by 8 layers of fiberglass separator and a CC4 carbon electrode. I also made sure to sand the graphite electrodes in the Swagelok cell to make sure their exposed surface was pristine. I put 50uL of the electrolyte on the cell but I won’t know how much ended up in the separator until I open the cell after testing and weight the wet components.

The solubility of Zinc Bromide is exponentially greater than that of Zinc Sulfate, Sodium Bromide and Sodium Sulfate so mixing a solution of Sodium Bromide and Zinc Sulfate generates a concentrated solution of Zinc Bromide and precipitates almost everything else. At 0C the solubility of ZnBr2 is still 311g/100mL while that of Na2SO4 drops to 4.76g/100mL and that of ZnSO4 drops to nearly 0. It is important to keep an excess of Zinc Sulfate in the reaction though as the solubility of NaBr is still quite high at 0C, reaching more than 79g/100mL.

201981 — On most late-model vehicles, the wheel bearings are sold as a complete hub-unit assembly that includes a sealed bearing, flange and an ABS wheel ...

The problem – which I have lived through experimentally – is that the solubility of TBABr in the presence of ZnBr2 is quite terrible. The TBABr is extremely soluble in water – you can easily prepare a 50% solution by weight in distilled water – but it precipitates back very aggressively when put it into contact with a solution of zinc bromide. The image above shows you what happens when you mix a 1M solution of TBABr with a 0.5M solution of ZnBr2. The authors of the paper probably saw this issue and immediately recognized this as a potential problem for their batteries, my intuition is that they did run and have results for some cells using TBABr, but the results were probably so much worse than those of TPABr, due to this solubility issue, that they simply did not publish them.

The BSN / BSF range of bearings are support bearings designed to specifically meet these demanding requirements. The double row configuration, with a 60 ...

A Ball Bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The image above shows you the layers of a Zn-Br battery that was taken apart after 15 cycles, charging the cell to 15mAh at 15mA and discharging to 0.5V, the cell has a diameter of half an inch. As you can see, the fiberglass separator layers look very yellow and, although it would be tempting to assign this color to the presence of elemental Bromine, which is true in part, cells constructed with high purity ZnBr2 solutions do not show such a strong yellow coloring. The yellow color is in large part caused by the oxidation of Fe+2 to Fe+3.

I wrote a post a while ago about how to prepare solid Zinc Bromide from Zinc Sulfate and Sodium Bromide through the use of water and isopropyl alcohol. However, this method has substantial issues when it comes to its practical implementation, as taking ZnBr2 out of solution is an arduous process that can also be dangerous due to the often aggressive splashing of hot concentrated ZnBr2 solutions. Taking the Zinc Bromide to a solid also seems unnecessary given that in the end we want to end up with ZnBr2 solution for batteries. What if we could just mix Zinc Sulfate and Sodium Bromide and somehow end up with a solution known Zinc Bromide concentration after precipitating the Sodium Sulfate? I will tell you how to do just that in this post.

It is also worth noting that this ZnBr2 solution will contain a significant amount of peroxide so you either need to heat the solution up to fully decompose the peroxide or wait till all the peroxide is decomposed at room temperature before actually using the solution in a battery. To be absolutely sure, you can also use H2O2 testing scripts (like these), to figure out whether you have any peroxide left before considering a solution to be battery-ready.

Zinc-bromine battery energy density

My initial tests with it involved testing its solubility in Zinc Bromide solutions. The solubility of TMPhABr in pure water is not indicated clearly anywhere, but I assumed its solubility would be similar to that of trimethylbenzylammonium bromide (TMBABr) or tetrapropylammonium (TPABr) bromide, both which have solubilities of around 10% by mass in water at 25C. My initial tests have confirmed this suspicion with solutions at 10% by mass being easy to prepare at 20-25C. I didn’t try to prepare more concentrated pure solutions as my objective is to judge its solubility in the presence of Zinc Bromide.

The characteristics of this inverted battery were actually not bad to begin with, achieving max CE and EE values of 81% and 61% respectively. However the discharge curves start showing significant deterioration around the 10th cycle, with strong drops in the discharge voltage around 3-4 mAh into the discharge cycles. This was also shown as a strong decay in the average discharge potential, which during the 15th cycle was around 6% lower than the starting value. This speed of decay is dramatically faster than for Zn-Br batteries created using high purity ZnBr2 solutions.

The above implies that you need to get rid of these Fe impurities if you expect to be able to run a Zn-Br battery that lasts for a long amount of time. Thankfully there is a pretty easy way to do this, which we know from the literature surrounding the purification of Zinc brines (see here). The trick is to use a 3% hydrogen peroxide solution for the preparation of your ZnBr2 solution, instead of distilled water, when you dissolve the Zinc Sulfate and Sodium Bromide salts. This causes all the Fe to be oxidized to Fe+3 and to precipitate out of solution.

The only tricky part is taking the Zinc Bromide out of the final solution. I prefer not to heat it till it’s completely dry, since the sizzling and “eruptions” of the Zinc Bromide can be pretty aggressive as it tries to hold dearly to every milligram of water it can manage to. Besides, if you heat it to dryness it will quickly become wet again as it cools unless you immediately put it inside a desiccator. It is therefore preferable to put this in a desiccator as soon as Zinc Bromide crystals start to appear and let the drying agent get all the water out of the Zinc Bromide. Note that a desiccator doesn’t need to be anything fancy, some air-tight tupperware you fill with a good enough drying agent can do (the drying agent needs to be more hygroscopic than Zinc Bromide).

The TPABr is most probably a significantly better sequestering agent because it’s likely significantly more soluble than TPABr in Zinc Bromide solutions. This agent is however unlikely to be soluble enough to support very large capacity solutions (>= 2M ZnBr2).

2017113 — If you do jack it up, they do make noise with little or no play in them. It is possible. If you shake it and its loose AF, you know which is bad ...

The first test I performed to evaluate this was a 0.25M solution of Zinc Bromide which was able to dissolve 0.12M of TMPhABr with no problems. I then increased the amount of ZnBr2 to 0.5M – which is what the authors of the Chinese paper using ZnBr2+TPABr use – and I was able to dissolve 0.25M of TMPhABr without issues. With this result I know I will be able to at least reproduce similar experimental conditions to those achieved by the Chinese researchers, something that I could never do with TBABr due to the solubility issues mentioned before.

The 2020 Chinese paper we’ve discussed previously in this blog goes around this problem by using a sequestering agent that forms an insoluble perbromide, tetrapropylammonium bromide (TPABr). Notably the paper uses TPABr instead of tetrabutylammonium bromide (TBABr) which is almost an order of magnitude cheaper due to its significantly wider array of industrial uses compared to TPABr. Not only that, but the TBABr perbromide is even more insoluble, so the chemistry should be even better, right?

Specifications · Bore Diameter mm. 17 · Bore Diameter Inches. 0.6693 · Bore Diameter Tolerance. -.0003 · Outside Diameter mm. 40 · Outside Diameter Inches. 1.5748.

Znbrprice

As I’ve mentioned in previous posts, tetrabutylammonium bromide (TBABr) is not a very good sequestering agent for static Zn-Br batteries due to its very low solubility in Zinc Bromide solutions. To solve this problem, I have decided to test trimethylphenylammonium bromide (TMPhABr) as a potential replacement, since this salt also forms and insoluble perbromide but – due to its significantly higher polarity and lower molecular weight – should be significantly more soluble than TBABr. I ordered it from Alibaba around one week ago and recently got it delivered.

What you are left with is a concentrated solution of ZnBr2 of unknown concentration. Since we do not know how much the volume of the solution changed due to the reaction and some volume of solution is always left wetting the remaining solid, we cannot accurately determine the molarity of the solution from the things we added and what we obtained. We need to perform some measurements to get an idea about how much ZnBr2 we have in solution.

Moreover, the Zinc anode is usually a grey or black color in batteries created with high purity ZnBr2 solutions, while in this case, it looks a lot like a rusted piece of Iron. This is no coincidence, as Fe is actually reduced in the anode and then oxidized to insoluble Fe oxide/hydroxide species. The first two layers of the battery show the strong presence of these red Fe+3 oxides, which are non-conductive and significantly hamper the performance of the battery.

Although Zinc Bromide is a readily available commodity chemical in some parts of the world (readily available in bulk quantities or for businesses), it is difficult to source in places like the US due to a lack of retail applications to justify its sale to the general public. Small amounts can be bought from sources on ebay/amazon, but the cost can often be above 1 USD/gram with similar costs from Alibaba when buying small quantities (<10kg). For people wanting to do small/medium scale experimentation on Zn-Br batteries, it is often impractical to buy in the necessary quantities, so a low cost synthesis of Zinc Bromide from readily available chemicals is desirable.

Single row SKF deep groove ball bearings are especially adaptable. They have a simple design, are non-separable, and are suitable for high speeds.

Since Zinc Sulfate Monohydrate and Sodium Bromide are both widely available almost anywhere for really low prices, this should allow a lot of people to experiment with these batteries with low costs, yet retain the ability to understand what the concentration of their electrolyte is.

ZnBr2

My solution to this problem is to use a readily available organic solvent – rubbing alcohol – to help speed up the process and achieve better results. Here’s a summary of the synthesis for a small amount:

With that said, this process is absolutely necessary to build Zn-Br batteries if you’re deriving your Zinc Bromide from an impure source, as a Zn-Br battery containing large amounts of Fe will degrade and stop working pretty fast as a function of time. If you want to test your ZnBr2 solution you can add a couple of drops of H2O2 to a sample of it and see if any Fe precipitate forms.

Znbrfor sale

To test how far I could take this I then attempted to prepare a 1M solution of Zinc Bromide and see if I could get 1M of TMPhAbr to go with it. Sadly at this point the concentration of TMPhABr is already too high – would be close to 10% by weight of the solution – so it was actually not possible to get to this point. This means that the practical limit of this battery will be to have around 0.25M of TMPhABr dissolved, which is probably a realistic limit for most quaternary ammonium salts since we are unlikely to get an effective sequestering agent – not electrochemically active and with no effect on pH – with a molar mass significantly lower than that of TMPhABr at a similar price point.

This page provides June 20, 3982 day and night choghadiya (also known as Chogadia) timings for Mountain View, California, United States.

Once you know the approximate concentration of your solution you will know how much you would need to dilute the solution to arrive at your desired concentration. Solutions produced with the above method are bound to be in the 4-7M region, so you will probably need to dilute them to arrive at a concentration that is better suited for the ZnBr2 batteries. With this information you can now prepare ZnBr2 solutions for your batteries without the need to prepare pure solid Zinc Bromide, have to deal with aggressively splashing solutions or have to go through any further purification processes.

8613869596835

8613869596835