2008 Nissan Altima Wheel Bearing Replacement Prices & ... - 08 nissan altima wheel bearing

Non contactseal bearing

Learn more below. DPP1 - Data Collection Principle. DPP2 - Accuracy & Retention Principle. DPP3 - Data Use Principle. DPP4 - Data Security Principle. DPP5 - ...

There are different types of rotary shaft seals, each with its own specific design and materials. Some common types include: Radial Lip Seals: These are the ...

Bearing sealmaterial

Jun 26, 2022 — 1 wheel bearing should be about $350 to replace for a shop. Run from that shop.

Aug 25, 2015 — lastly, could be a wheel bearing going bad. jack it up, pull the wheel and look around. if the pads look good and the dust shield clears the ...

Bearing sealtypes SKF

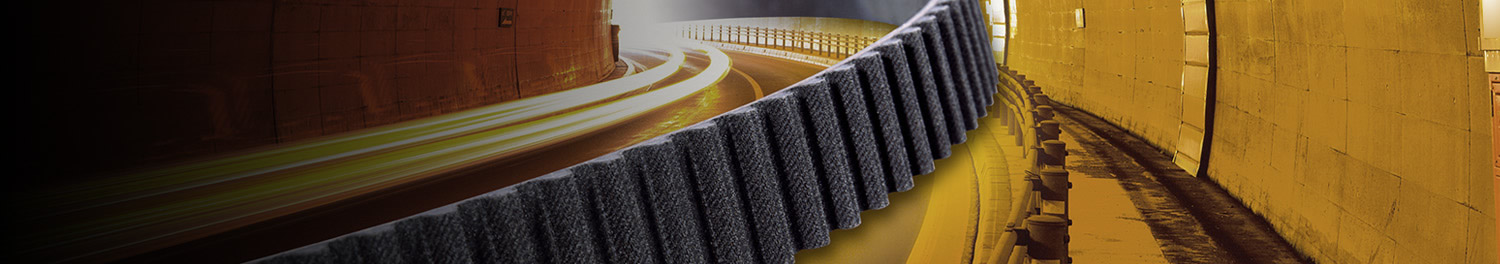

Belt drive components are subject to aging and wear. They therefore have to be regularly checked and replaced. The checking and replacement intervals are always specified by the vehicle manufacturer and must be complied with.

170.19 Construction and authority of chapter.--This chapter shall, without reference to any other law of Florida, be full authority for the issuance and ...

Bearing sealtypes

Feb 7, 2019 — As best as any grease is only proper cleaning procedures and application followed by torque and end play check provide superior results.

DriveAlign™ Laser Alignment Tool ... Made for fast, easy operation the DriveAlign™ Laser Tool helps automotive technicians quickly identify misaligned pulleys and ...

Rubbersealvs metalseal bearing

Seal Bearingbike

Provides smooth, ball bearing track system for sliding 1/4" glass doors to move back and forth with ease.

Axis needle roller thrust bearings are ideal for medium- and heavy-duty applications where space is limited and only axial loads need support.

2024527 — Driving with a bad wheel bearing isn't exactly a safe routine. If left unaddressed, you might lose control of your vehicle, develop braking ...

In addition to the timing belt, the Continental kits contain all the relevant components required to change the belt properly, including the water pump.

Timing belts must not be creased since this will cause the glass-fiber tension members to break inside the belt. The belt’s load-carrying capacity is then no longer assured and it can tear. Consequence: Engine failure.

8613869596835

8613869596835