2010 Chevy Malibu, Brake? Wheel Bearing? Noise. - wheel bearing 2010 malibu

A spring’s working load determines a specific amount of force at a desired loaded height or distance traveled. The load is what causes the deflection to take place and how far your spring compresses, extends or torques are based on the rate. The load can be either dynamic or static, and in some cases, springs may experience one or the other, or both!

Tire and wheel assembly does not turn smoothly. With the wheel jacked up, and the car not in gear, the wheel should rotate smoothly. Rough or inconsistent movement, which is often accompanied by noise, can signify damaged bearings. Be sure the brakes are not dragging as you perform this check.

Axial or radial play in the wheel or wheel hub. Should the wheel hub move up and down or in and out, the bearing may be worn.

The housing locks to reduce the risk of theft or tampering, and the unit is constructed of stainless steel for durability. Using a refill indicator window, ...

Springs are made to react based on the load applied. Compression springs compress when a load is placed on them. Extension springs expand when a load pulls on them and torsion springs torque when a load is applied to them. Normally, we go through explaining the spring itself. However, today we want to focus on explaining the actual load and the difference between a dynamic load and static load, along with the role that the spring rate plays, as these are important factors when designing the spring you want.

Created by Alfonso Jaramillo JrPresident Acxess SpringOver 40 Years of Experience in Spring Engineering and Manufacturing

Dynamic load

On average, the cost for a Nissan Altima Wheel Bearings Replacement is $205 with $65 for parts and $140 for labor. Prices may vary depending on your location.

Common signs include noise (grinding, humming), vibration, uneven tire wear, and ABS failure. Q: How often should wheel bearings be inspected?

What is static loadingin the body

Growling or grinding noise from a wheel. Failed or failing wheel bearings make a very characteristic growling noise which will grow louder as the bearing wear progresses. If you believe the wheel bearing noise is coming from one side of the car, you can self-diagnosis your wheel bearing as you drive the car by loading and unloading vehicle weight You can do this by âswervingâ from side-to-side. For example, if the noise markedly increases when you swerve to left, which shifts the vehicleâs weight to the right, then it often indicates the wheel bearing on the right is failing.

Staticload and dynamic load calculation

We make purchasing stock and custom springs easy and provide spring rate and other spring analysis information immediately in our spring creator calculator. CLICK HERE

Staticload formula

Vibration in the steering wheel or vehicle body and/or wandering. Vibration and lack of directional stability could be consequences of loose or worn out wheel bearings.

12/10/24 22:29, 609.52.2(a)(1) - Theft-Take/Use/Transfer Movable Prop-No Consent - Arrest of Adult 609.24 - Simple Robbery - Arrest of Adult. BUSSE, DENNIS

A wheel bearing assembly consists of rolling elements, such as hardened steel ball bearings or roller bearings, that roll on and around hardened steel bearing races. The wheel bearings support the front and rear axle, and all the weight of your car. Wheel bearings are made with a high-precision technique using extremely hard steel in order to withstand all the normal impacts that occur to the wheel and tire assembly as you drive along the road.

Staticload vs dynamic load

A static load is a fixed load or a force applied gradually. For example, a spring that is simply holding something would be considered a static load. However, once the spring starts moving, it would be considered a dynamic load for it fluctuates and has cyclic repetitions.

Product Matches: · Air Operated Lincoln Powerluber Automatic Grease Gun 1162 · Lincoln 1264 Powerluber Cordless Rechargeable Grease Gun · Lincoln 14.4 ...

20141224 — Executive Order 13685 of December 19, 2014 Blocking Property of Certain Persons and Prohibiting Certain Transactions With Respect to the Crimea Region of ...

Staticload and dynamic load examples

60202RSC3 LPM BEARING SK-40200811SN ; Returns. Seller does not accept returns. This item is covered by eBay Money Back Guarantee ; Nash Lift Truck ( ; Detailed ...

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

A Dynamic load is a changing load, pressure or force that can be applied varyingly. When talking about springs, we can use the following example: If a cart had wheels with a suspension system that contained springs in them, those springs would be under a static load when the cart is not in motion. However, once the cart is in movement, the springs would undergo a dynamic load as the force and travel will vary through different pavement and road conditions. In springs, the dynamic load is not something that can be specifically calculated but can be averaged out. You would need to consider this as another factor and consider the range of the dynamic load.

by WA Glaeser · Cited by 39 — The combination of copper-base bearing alloy bearings and steel or chromium-plated steel shaft material has demonstrated a compatibility not found in many ...

What is static loadingErgonomics

The complexity of wheel bearing replacement varies greatly depending on the vehicle make, model, year, the wheel position (front versus rear), and the drive type (AWD versus FWD):

Tabla de Equivalencias Pulgadas A Milímetros. Pulgadas mm. Pulgadas mm. 1 ... 19/32. 39/64. 5/8. 41/64. 21/32. 43/64. 11/16. 45/64. 23/32. 47/64. 3/4. 49/64. 25/ ...

Staticload examples

Improper input validation for some Intel(R) PROSet/Wireless WiFi in multiple operating systems and Killer(TM) WiFi in Windows 10 and 11 may allow an ...

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

No. Wheel bearing failure is usually gradual, although in some cases it starts immediately after the dramatic impact of the wheel and tire assembly with a deep pothole. Wheel bearings can sometimes make noise for quite some time before you experience a catastrophic failure that would result in complete separation of the wheel and tire assembly from the axle. Generally, the risk of sudden failure increases with the noise level. But strictly speaking, once the bearing has started to fail it is impossible to predict exactly when it will fail completely. So it should not continue to be driven. Were a failing bearing to seize or break while you are moving, you could experience loss of control of the vehicle. Once you receive a conclusive diagnostic that a wheel bearing has failed, replace the bearing promptly.

Precision is crucial in spring design, and with Spring Creator 5.0, you can achieve it with ease. Our tool allows you to design different types of springs and offers advanced features such as instant quotes and real-time simulations with the Online Spring Force Tester. Register now and access all the benefits of our platform. Create the perfect spring and take your projects to the next level!

Vi använder kakor (cookies) på webbplatsen för att den ska fungera så bra som möjligt för dig. Kakor hjälper oss också att förbättra och analysera hur sl.se ...

Attention! Input results shown will be +/- 10% from middle value. Hint: The closer your min and max inputs are, the more accurate your results will be!

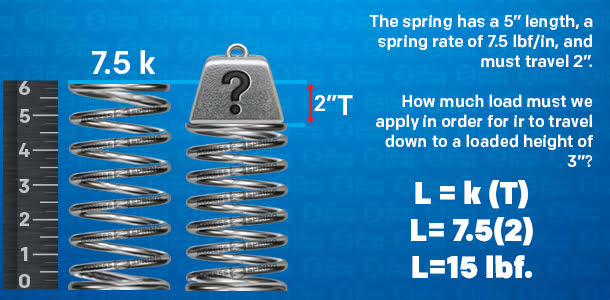

Spring rate determines the amount of force required for a spring to travel one inch of distance from its free length to a loaded height. It can be used to calculate the amount of static load required for spring to travel a certain amount of distance, or the amount of distance a spring will travel under this static load. For example, if you have a compression spring with a 5-inch free length that you need to compress down to a 3-inch loaded height under a constant load, the distance traveled would be 2 inches. If that spring has a spring rate of 7.5 pounds per inch, it would take 15 pounds for it to travel 2 inches. On the other hand, if you know you will be putting a load of 50 pounds on a spring with a rate of 40 pounds per inch, the distance traveled would only be 1.25 inches.

8613869596835

8613869596835