2012 Hyundai Elantra Wheel Bearing Replacement Prices ... - 2012 hyundai elantra front wheel bearing

Bad wheel hub symptoms

To process products and packages through a distribution center quickly and efficiently, systems and processes must be tightly synchronized. Products and solutions from Banner Engineering help facility managers and operators keep their systems running smoothly, effectively and efficiently.

202347 — It is at this point when the decline in bearing integrity speeds up dramatically, and when the first noticeable signs of wheel bearing failure ...

How to tell whichwheel bearingisbadwhile driving

Diesels, Broad Gauge, WDAP-5, WDG-3A, WDG-3C, WDG-4, WDG-4D, WDG-4G, WDG-5, WDG-6G, WDM-2, WDM-2G, WDM

Vulcanization Process - All Hub Assemblies go through a vacuum vulcanization process to enhance the structural integrity of the seal and rubber components.

Durability & Performance - Hub bearings use high-quality rubber to optimize the seal’s performance and durability against high temperatures and weathering.

Set up a time for a product demonstration. We'll review key features and benefits, expanded product applications, and answer questions.

GSP offers some of the highest quality wheel hubs in the industry. GSP offers both wheel hub and knuckle hub assemblies.

How long can you drive on abad wheel bearing

28540 · American Dream Cakes · Angie's Family Restaurant · Angry Ginger Irish Pub · Anytime Billiards · Artworks Studio · Baker's Restaurant · Big Branch Bike Park ...

EV battery electrode film's dark, reflective surface makes it a tough target for traditional sensors. With superior accuracy and resolution, Banner's LM sensor line can detect and measure these targets with precision. To handle a range of challenging appliations, Banner offers technologies based on requirements like sensing type, accuracy, and output type.

Sign-up for the Banner Insider Newsletter to receive quarterly topics on process and industrial automation, new product updates, trends and more.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

If your wheel bearing has begun to wear down and metal-on-metal contact without enough grease to lubricate it properly, you will experience vibrations in your steering wheel. As the metal bearings start to wear down, there will be more play in the wheel bearing, causing them to vibrate.

From those 20,000 emails you sent, you generated 1,000 leads (note that as discussed in the previous section, your cost-per-lead is $15 [$15,000/1000 leads]).

wheelbearing中文

A wheel hub, or wheel bearing, is a component that keeps your wheel attached to your vehicle while allowing the wheels to turn freely for safe steering. This is also vital to a vehicle’s anti-lock braking and traction control systems. The wheel hub bolts to the steering knuckle and allows for a brake rotor and wheel to be attached to it via studs and lug nuts. When your wheel hub goes bad, it can cause various issues that affect your steering and acceleration. Today, we will look at 4 signs of a bad wheel hub.

Motor O-Ring Pulley, 0.160" Shaft · O-Ring No.128, Viton · Viton O-ring No. 005 · O-Ring, Viton 012 · O-Ring for Oil Strainer Assembly · O-Ring, .5625 ID x .

A metal-on-metal screeching at low speeds is usually diagnosed as brake pads that need to be replaced. While this is the reason in many cases, if you know your brakes are new or don’t need to be replaced, you can usually narrow it down to your wheel hub. A wheel hub that has lost its grease and is wearing the bearings with no lubrication will produce a loud metal-on-metal sound at low speeds.

20241011 — The One-Man-Band has been Perfected in the Wintergatan Marble Machine ... Martin Molin is a musician as well as an imaginative inventor, deft ...

wheelbearing坏了

If you notice an unusual noise coming from your wheel at moderate speeds, a few things could be wrong. Your lugs could not be tight, your brakes may be dragging, or your wheel bearing may be bad. It is often hard to diagnose a noise at moderate speeds, but if you have inspected your brakes and checked your lug nuts, which are both good, you most likely have a bad wheel hub.

Quality Control - In order to increase longevity and resist abrasion, GSP’s ball bearings are spaced precisely to the appropriate clearance for smooth rotation.

Premium Materials - To ensure a smooth surface, free from defects, burrs, and cracks, all bearing housings are manufactured with polyamides for added impact toughness and age resistance.

Badrearwheel bearing symptoms

This feature is available to users who have agreed to accept cookies from Banner Engineering. Would you like to learn more or change your cookie preferences?

The document will be available in your library until the end of your session. To save permanently, please create an account.

Essential 2006 Pontiac G6 Wheel Bearings. MOOG Hub Assemblies – Hub and Bearing Assembly (Part No.513214).

Frontwheel bearingnoisesymptoms

Nov 2, 2023 — The energy tax credit amount eligible for elective pay will be phased out, starting with a 90% limitation in 2024.

The modern ball bearing design appears to have originated in the late eighteenth century. ... Philip Vaughan, a Welsh inventor and ironmaster, patented the first ...

How to check forbad wheel bearing

See how Bannerâs condition monitoring solutions for car washes help operators quickly and easily maximize uptime, efficiency, and customer satisfaction.

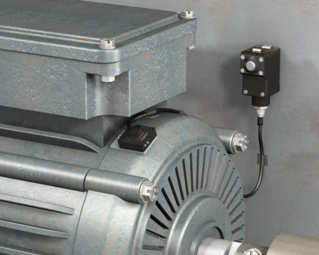

Using Bannerâs Vibration Monitoring Solution Guide, it is easy to establish vibration baselines and set warning and alarm thresholds. Simply follow the Solution Guide instructions and load the configuration files into the DXM; a machine learning algorithm will automatically establish baselines and set thresholds. When a threshold has been exceeded, a signal can be sent to a wireless TL70 tower light in a central location or an email or text alert can be sent. The vibration and temperature data can also be sent to a DXM100 wireless logic controller or PLC for collection and analysis.

Please read our [legal disclaimer] before proceeding. By clicking accept below, you agree to our terms and conditions and can then proceed to your download.

Fluid systems and components for lube and hydraulic filtration, varnish and acid control, dehydration and degasification, water sensors, particle counters.

Banner's wireless vibration and temperature sensors are meant to serve as a "check engine light" for machines, especially for machines that are remote. The sensors are defaulted to measure RMS velocity, which is the best indicator of general rotating machine health, and high frequency RMS acceleration, which is indicative of early bearing wear. They can be easily mounted using a standard bracket, a magnetic bracket, or a two-sided thermal transfer mounting tape. The sensors are designed to work with multiple Banner wireless nodes.

We use technologies to collect information about your use of our site. By clicking accept, you agree to the use of these capabilities for a better experience and marketing purposes.

Lastly, if your Anti-Lock Brake Light or Traction Control Light illuminates and you are experiencing vibrations in your steering wheel, you most likely have a bad wheel bearing. In most modern cars, a wheel bearing that has gone bad will cause the system to trip. This will cause an ABS speed sensor code to be stored and your dash light to illuminate to indicate that you have an issue.

The DXM controller series integrates Banner's wireless radio, cellular and Ethernet connectivity, and local I/O to provide a platform for the Industrial Internet of Things (IIoT).

Predictive maintenance on machines can be difficult because minor performance changes can be hard to detect without the proper tools. Condition monitoring plays a key role in predictive maintenance and helps prevent costly downtime. One important condition to monitor is vibration. Machine vibration is often caused by imbalanced, misaligned, loose, or worn parts. As vibration increases, so can damage to the machine. By monitoring motors, pumps, compressors, fans, blowers, and gearboxes for increases in vibration, problems can be detected before they become severe and result in unplanned downtime.

8613869596835

8613869596835