204-KRRB-AH01 INA - krrb

With over 15 years of technical writing and mechanical engineering experience, David Allister holds a Bachelor's degree in Mechanical Engineering from the University of Michigan. His passion for innovation and technology has made him a leading voice in industry trends, advancements, and best practices. David joined our team in 2021, bringing a wealth of experience from his time at renowned automotive companies, where he led numerous projects from planning to execution. Beyond his professional life, David is an avid cyclist and enjoys restoring vintage bicycles, showcasing his love for intricate mechanisms and sustainable transportation solutions.

From everyday parts to hard-to-find items, our catalog of products is vast. Can’t find what you need? No problem. Call us, and we’ll help you find it!

Clean the areas around the bearings regularly, protecting them from water, dirt, and debris build-up that can accelerate wear.

Regal Rexnord

For light-duty applications, a bushing type follower can be used. A plastic bushing is used to reduce friction, which also provides a maintenance-free follower. The disadvantage though, is that it can only support light loads, slow speeds, no thrust loads, and has a temperature limit of 200 °F (93 °C). A bushing type stud follower can only support approximately 25% of the load of a roller type stud follower, while the heavy and yoke followers can handle 50%.

Since 1937, McGill cam follower bearings have maintained the leading position through ongoing development and improvements to the CAMROL® line of bearings. As today’s industry leading manufacturer of quality cam follower bearings, McGill has worked to develop products with many features to prolong bearing life in the areas of lubrication requirements, operating conditions, and application environments. With more than 1,400 standard designs to choose from, McGill offers an extensive and comprehensive range of cam follower bearings to suit any application. Learn more about the CAMROL® line, and find all the McGill cam follower bearings you need through ProSource.

McGill cam follower bearings, also known as track followers, are a specialized type of roller or needle bearing designed to follow cam lobe profiles. Cam follower bearings come in an array of configurations, but their most defining characteristic is how the cam follower mounts to its mating part. Stud-style cam followers use a stud to mount while the yoke style has a hole through its center. All cam followers can be track followers, but not all track followers are cam followers. Some track followers have specially-shaped outer diameters (or OD) to follow tracks. For example, track followers are available with a V-groove for following a V-track, or the OD could also have a flange allowing it to follow the lip of the track.

We will examine crucial aspects such as the vehicle’s make and model, the type and quality of replacement bearings, labor costs, and any additional components that may require replacement.

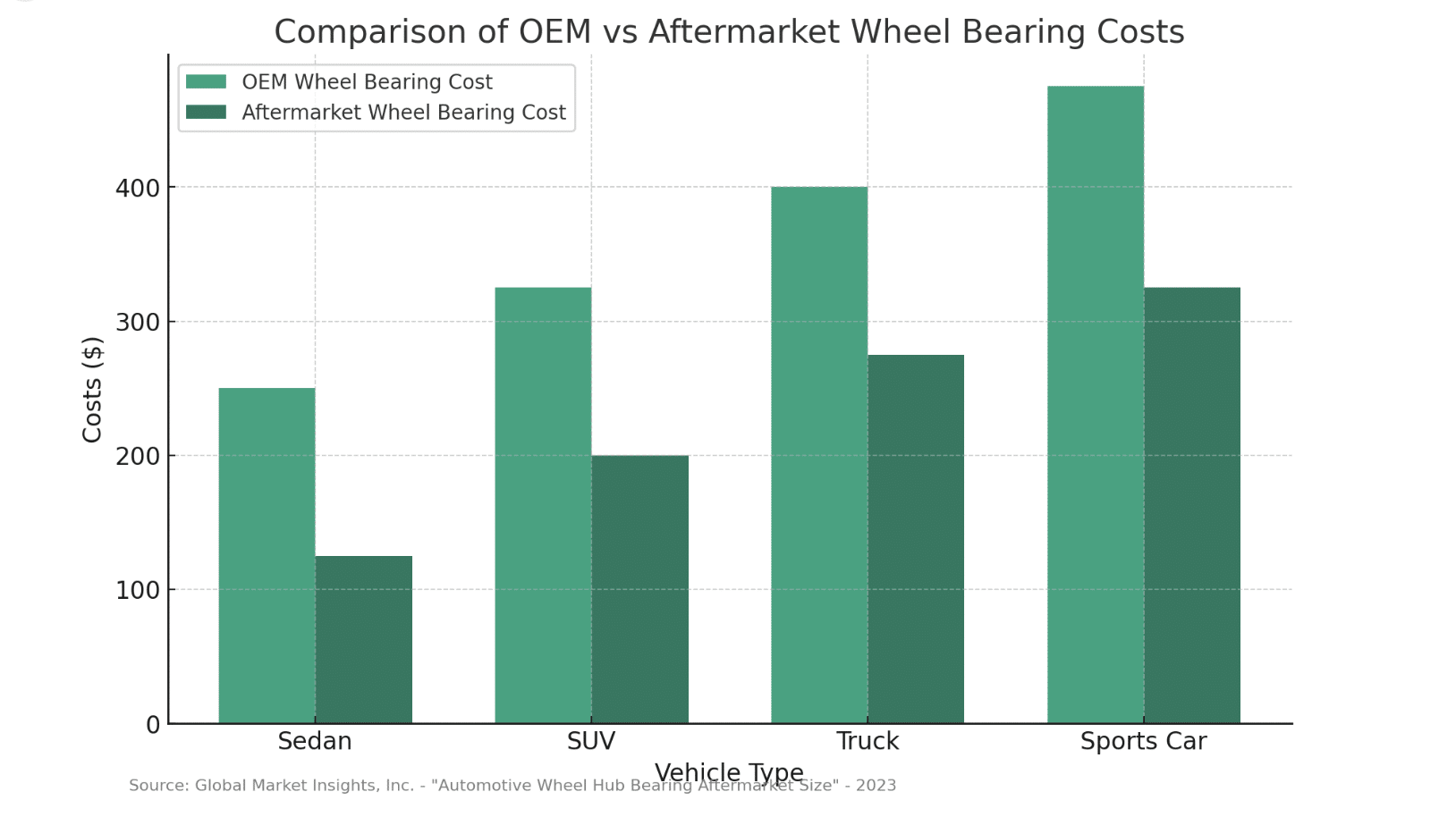

The average wheel bearing replacement cost can vary significantly based on your vehicle’s type and the specific bearings required.

McGill cam follower bearings, also called “track followers,” are designed to follow tracks or cams within a vast range of linear motion systems. The modern stud type follower was invented and then patented by Thomas L. Robinson of the McGill Manufacturing Company in 1937. These bearings soon replaced the standard bearing/bolt combination, and were easier to use because the stud was already incorporated, plus they were engineered to handle larger loads.

Additionally, avoid high-impact loads or harsh driving conditions that could subject the bearings to excessive stress and potentially damage them prematurely.

McGillbearing

This specialized type of needle or roller bearing is designed to follow cam lobe profiles. While these McGill cam followers are somewhat similar to roller bearings. Standard ball and roller bearings are made to be pressed into a rigid housing for circumferential support– keeping the outer race from becoming deformed and keeping the race cross-section relatively thin. Conversely, with cam followers, the outer race is loaded at a single point, so the outer race requires a thicker cross section to reduce deformation during use.This means the roller diameter must also be decreased, which consequently reduces the dynamic bearing capacity.

Regular maintenance and professional inspections are essential for ensuring the safety and optimal performance of your vehicle’s wheel bearings over time.

We strive to provide high-quality, stylish home decor pieces to help you create the perfect look for your unique space. Our blog offers helpful tips and tricks to bring your dream home to life!

Replacing worn wheel bearings is critical for maintaining your vehicle’s safety and performance on the road. Damaged or failing bearings can lead to many issues, including uneven tire wear, steering instability, and even the potential for complete wheel separation if left unchecked for an extended period.

Order right away, pay in 30 days. We offer net 30 payment opportunities for qualified buyers for quick and easy transactions.

It’s also essential to consider the expertise and labor rates of your chosen service provider, as these can significantly impact the overall cost of the replacement process.

McGill Cam Followerscatalog

Costs can also vary based on your geographic location and the specific service provider’s labor rates. Urban areas and dealerships often command higher prices than independent mechanics in more rural regions.

By addressing bearing issues promptly and scheduling timely replacements as needed, you can avoid more costly repairs down the line and optimize the performance of these critical components that play a vital role in your vehicle’s handling and stability.

Regal Rexnord China

It’s essential to note that several additional factors can influence these costs, such as the vehicle’s make, model, age, and overall condition.

Our Chattanooga-based team is invested. We care about what we do, and we care about the customer. We won’t rest until you find the products you need.

To illustrate the potential cost variations, replacing wheel bearings on a standard sedan could cost between $100 and $300 per wheel, including parts and labor. However, for a luxury SUV equipped with premium bearings, the cost could escalate to $200 to $500 per wheel, not including potential additional component replacements that may be necessary.

In some cases, additional components like wheel hubs, seals, or axle nuts may need to be replaced alongside the bearings, further increasing the overall cost.

Older, high-mileage vehicles may require additional repairs or replacements during the bearing installation process, increasing expenses.

Enjoy everyday savings when you shop ProSource. Not only do we have extensive inventory, but our prices are the best around!

McGill camfollower catalog pdf

Let’s embark on this informative journey and empower you with the knowledge to navigate the dynamics of wheel bearing replacement costs confidently.

The most common anti-friction element employed is a full complement of needle rollers. This particular design is able to withstand high radial loads but no thrust loads. The caged needle roller features a similar design, which also uses needle rollers, but with a cage to keep them separated. This design provides for higher speeds, but also decreases the load capacity. The cage also increases internal space so it can hold more lubrication, which means that relubrication is less frequently necessary.

Additionally, we will emphasize the importance of timely bearing replacement and provide insightful information to help you budget effectively.

With the right care and attention, your new bearings should provide smooth, reliable performance for years, contributing to your vehicle’s overall safety and longevity.

McGill boasts one of the industry’s most extensive lines of cam followers. They produce several different types of cam followers including: track roller, corrosion resistant, heavy duty, and their CAMROL series of cam followers. These quality McGill cam follower products offer increased contamination resistance, extended product life, and lubrication for life capabilities.

We’ll get what you need boxed up and on its way to you pronto. No hassle. No worry. Just the products you ordered– shipped directly to you.

This comprehensive blog aims to equip you with a thorough understanding of the factors influencing wheel bearing replacement costs.

Inevitably, these components wear out over time due to the constant stress and friction they endure, necessitating replacement.

A roller design can be used for heavy duty applications. This design employs two rows of rollers of larger diameter than used in needle roller cam followers to increase the dynamic load capacity while also providing thrust capabilities. This design can also support higher speed applications than the full complement design.

8613869596835

8613869596835