212-320-32-38-80 - Remanufactured Air Suspension Strut ... - 320-32

4. Grime Defense Outboard Seal helps prevent contaminant buildup on the assembly exterior, working to shield bearings from friction-and corrosion-causing moisture and grime

Privacy Policy | Cookie Settings | Cookie Notice | Terms & Conditions | Anti-Human Trafficking | Warranty ©2022 DRiV Incorporated. All rights reserved.

Wheel hub assemblydiagram

It is commonly referred to as "bearing" in English, while in Taiwan, it is usually called "軸承". The fundamental principle of a bearing involves the placement of rolling elements, such as balls, needles, or rollers, between the inner and outer rings to facilitate smooth rotation of the shaft.

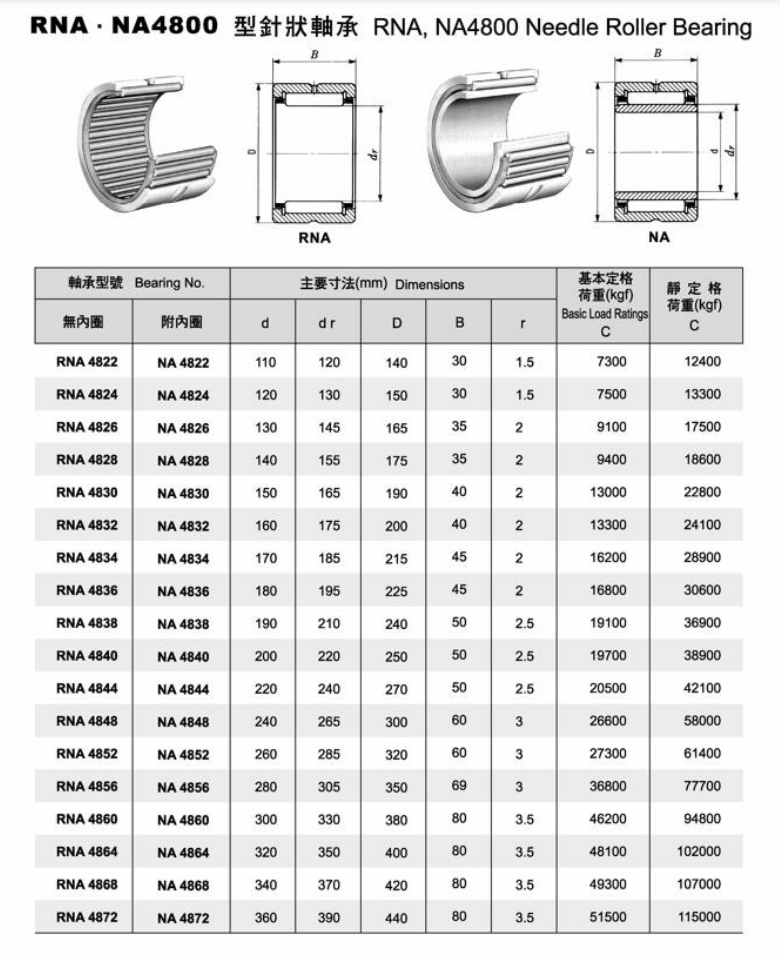

Utilizing a needle bearing size chart is essential for several reasons. Firstly, it enables accurate identification of the appropriate bearing size needed for a specific application. By referencing the chart, engineers and technicians can match the required dimensions and load capacities to the available needle bearing options. This ensures compatibility and optimal performance.

Wheel Bearing Hub AssemblyFront

In this article, we will delve into the details of a needle bearing size chart, explaining its significance and providing essential insights to help you make informed decisions when selecting needle bearings for your specific applications.

The catalog provides in-depth specifications and technical details about various needle roller bearings, including bore diameter, outside diameter, width, and other critical dimensions.

9. Increased Ball Size, Advanced Raceway Design, and Precision Matched Components for lower friction, increased load capacity and longer service life

Wheel hub bearing

Hub and wheel bearing assemblyreplacement

To utilize the needle bearing size chart effectively, it is crucial to understand the specific requirements of the application. This includes factors such as the desired load capacity, operating conditions, speed limitations, and any special considerations unique to the industry or equipment.

MOOG’s commitment to continuous innovation means making existing designs even better. MOOG makes hub assemblies for a broad range of vehicles, so even older trucks can be fitted with our latest hub assembly innovations.

A needle bearing size chart is a comprehensive reference guide that presents crucial information about different types and sizes of needle bearings. It typically includes key parameters such as bore diameter, outside diameter, width, and load-carrying capacity. The size chart may also provide additional details, such as limiting speeds, tolerance classes, and available variations in cage designs and materials.

Secondly, the size chart facilitates accurate bearing selection by considering crucial operating conditions such as rotational speed,and load type. These factors greatly influence the suitability of needle bearings for specific applications.

Types ofwheel hub

Wheel Hub AssemblyKit

To obtain comprehensive information regarding the detailed dimensions of needle roller bearings, we recommend downloading our catalog.

In this article, we will explore the significance of the ball bearing size chart and understand how to interpret and utilize it effectively.

Frontwheel bearing hub Assemblyreplacement cost

Wheel hub assemblyparts

Hub assemblies are critical for safe and reliable operation of a vehicle — and they're subject to some of the harshest punishments the road can dish out. High temperatures, extreme stresses, water and contaminants can take a toll on hub assemblies that aren't up to the challenge. That's why MOOG engineers continually introduce purpose-specific innovations that stand strong against harsh conditions — and make MOOG hub assemblies durable and reliable for years of hassle-free operation.

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

A sleeve bearing (also known as a bushing bearing or plain bearing) is a straightforward and fundamental type of bearing. It primarily consists of an inner metal sleeve (known as the bushing) and an outer metal sleeve. Between these two sleeves lies a layer of special lubricating material, typically a sliding surface coated with grease or oil.

Needle bearings, also known as needle roller bearings, are precision-engineered components that are widely used in various industries for their ability to handle high radial loads in limited spaces. Proper selection of needle bearings is crucial for ensuring optimal performance and longevity of machinery and equipment. To assist in this process, a needle bearing size chart serves as a valuable reference tool.

Begin by identifying the key parameters needed for your application, such as the required bore diameter, outside diameter, and width. Cross-reference these dimensions with the available options in the size chart to find the suitable needle bearings size. Take into account the load-carrying capacity and other relevant factors to ensure optimal performance and longevity.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

8613869596835

8613869596835