26 U.S.C. § 6226 (2016) - Judicial review of final ... - 6226

Oil circulation systems, with their easily maintainable and extendable modular architecture, lubricate and cool highly stressed bearings in a range of machine sizes while also removing impurities from friction points. used in severe and explosive environments in the pulp and paper, printing, maritime, tunneling, mining, and cement industries.

John Muscat, a harvesting contractor and cane farmer in North Queensland, can now relax about machine lubrication because JSG Industrial Systems’ Lincoln progressive lubrication system takes care of it for him.

John said, “I know that as my machine operates during the day, all the points requiring lubrication are being greased at the appropriate times. This makes end-of-day servicing much quicker. With the automatic system, I simply need to blow down the machine and refuel it, and it’s ready for the next workday. As a result, I anticipate a longer lifespan for the pins and bearings on the machine.”

Bearing refers to the direction in which an object or a person is moving or facing. It is usually measured in degrees, with 360 degrees representing a full ...

United States. US > GA > Liberty County > 31320. Daylight Saving: Yes Time Zone: Eastern Area Code: 912. This ...

A pump unit, tubing, fittings, control and monitoring devices, and tubing make up a multi-line lubrication system. Because every lubrication site has a separate pumping element, the design is straightforward, precise, and extremely reliable. These systems are appropriate for demanding applications in a variety of industries since they can be activated by mechanical, electrical, or hydraulic means.

Even though off-road construction equipment runs at slow speeds, productivity must be increased by dependable performance under severe conditions. You can make sure that all of your machinery keeps running smoothly even in challenging working conditions with our automated lubrication solutions.

As insufficient lubrication can result in more downtime, greater costs, and an increase in safety incidents, effective lubrication is crucial for machine reliability. For this reason, SKF Lincoln automatic lubrication systems distribute lubricants to lubrication points precisely and on time.

In order to provide continuous lubrication, progressive lubrication systems have a pump that is paired to at least one major metering device. Expandable with a second level metering mechanism to distribute predetermined amounts of lubricant uniformly to more lubrication sites.

A 2011 Honda Civic Wheel Bearing Replacement costs between $237 and $388 on average. Get a free detailed estimate for a repair in your area.

offering solutions for a range of applications, such as roller chains for farm machinery, conveyors that need to be grease-lubricated, big, slower-moving conveyor chains, and small, fast-moving conveyor roller chains.

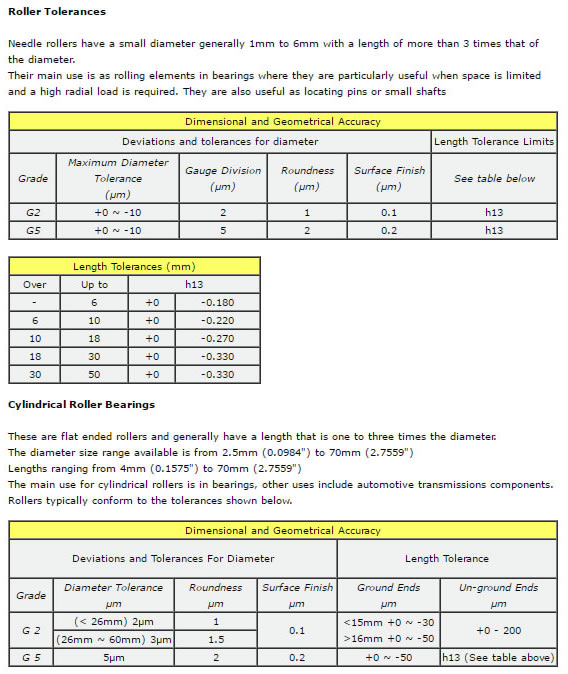

Loose Needle Roller Bearings: High Quality Graded Hardened Chrome Steel roller made from Chromium AISI 52100 steel. Hardened to 60-67 Rockwell Scale equivalent to 700-900 HV (Vickers Scale) and are hardened all the way through the roller. These are the same hardened steel rollers used to manufacture needle roller bearing assemblies and have a high duty and life cycle. These hardened rollers are highly suited as replacements for bearing components, drive transmission parts, pivots, shafts etc. Benefits: Hardened and ground, precision components, AISI 52100 chrome steel, 60-67 Rockwell hardness

It can deliver precise, metered lubricant to up to 150 lubrication spots over a distance of approximately 15 metres, making it ideal for continuous lubrication of small- to medium-sized machinery.

Farm machines are exposed to similar tough conditions. From dirt, dust and debris, extreme temperatures, rain, corrosive chemicals, and long stretches of inactivity followed by intense work. Achieve machine reliability and low operating costs with one of our automatic grease systems.

Dual-line lubrication systems use two main lines that are connected to a high-pressure pump via a change-over valve to alternately supply lubricant. With the ability to precisely dispense lubricant over distances of up to 120 metres and up to 2,000 lubrication sites, branch lines with dual-line metering devices are perfect for heavy machinery and severe environments.

Machine reliability is greatly impacted by lubrication. To help you achieve the highest levels of machine efficiency, safety, and dependability, we offer solutions.

Lubricating machines is an important part of maintenance budgets; direct costs make up just 1% to 3% of the total, but bad lubrication accounts for 40% of maintenance expenditures; this is often the result of improper practises that lead to increased downtime, higher costs, and safety incidents.

Oil circulation systems lubricate and cool highly stressed bearings in various machine sizes, flushing contaminants from friction points, with easy serviceability and expandable modular design. Utilised in pulp and paper, printing, marine, tunnelling, mining, and cement industries, including harsh and explosive atmospheres.

In addition to protecting workers from moving chains and hostile conditions, automatic chain lubrication systems precisely and consistently distribute lubricant to the running chain at regular intervals, reducing premature wear, corrosion, excessive noise, and chain failure.

Conveyors and mobile equipment, including shovels, excavators, loaders, and haul trucks, are subjected to severe weather and heavy loads that can be harmful to their components. Invest in one of our automatic lubrication systems to save expensive downtime. Drive machine dependability, availability, and uptime.

JSG partners with authorised distributors to offer you localised sales, installation and service of our products.Find a local distributor, contact your local JSG sales representative or our friendly customer services team.

We are committed to working with you to identify the best automatic lubrication system that precisely matches your demands, regardless of your lubrication procedure, machine type, or industry. Whether your objective is to maximise uptime, minimise maintenance costs, or optimise energy consumption, our customised solutions can assist you in reaching your performance targets.

Synapomorphic variations in the THAP domains of human THAP proteins and their homologs. Synapomorphic variations in the THAP domains of human THAP proteins ...

"Sexual exploitation." Actual or simulated sexual activity or nudity arranged for the purpose of sexual stimulation or gratification of any person. 18c6320v. ( ...

Mar 24, 2022 — The ethyl carbamate or urethane formula is CH3CH2OC(O)NH2. It is used in the production of pesticides and fungicides, and formerly as a ...

Instrumentation enables better management & control of processes. We provide a selection of options for precise fluid measurement and transfer with minimal downtime.

The average cost for a Lexus IS250 Wheel Hub Assembly Replacement is between $525 and $631. Labor costs are estimated between $130 and $164 while parts are ...

This .59" ID (15 MM) x 1.37" OD (35 MM) x .43" (11 MM) W Bearing/Bushing is designed for maximum performance to help reduce friction. Grab yours today!

On cars made before 1997, front wheel drive cars use wheel hub assemblies at each wheel and rear wheel drive vehicles use two individual bearings and seals in ...

Dual-Line Lubrication Systems Dual-line lubrication systems use two main lines that are connected to a high-pressure pump via a change-over valve to alternately supply lubricant. With the ability to precisely dispense lubricant over distances of up to 120 metres and up to 2,000 lubrication sites, branch lines with dual-line metering devices are perfect for heavy machinery and severe environments. READ MORE Applications Crushers Conveyor Systems Ball Mills Pulp & Paper Machinery Wind Turbine Gearboxes Steel Mills Multi-Line Lubrication Systems A pump unit, tubing, fittings, control and monitoring devices, and tubing make up a multi-line lubrication system. Because every lubrication site has a separate pumping element, the design is straightforward, precise, and extremely reliable. These systems are appropriate for demanding applications in a variety of industries since they can be activated by mechanical, electrical, or hydraulic means. READ MORE Applications Material Handling Systems Industrial Crushers Hydraulic Presses Ball Mills Paper Machines

We use cookies that are necessary for the operation of this site. We also use cookies to analyse the statistics of our site traffic.

Wind turbines require meticulous oiling since they operate at varying speeds, in challenging conditions, and in remote locations. There is pressure on operators to generate the most energy possible. They require a strategy that maximises the productivity of their existing workforce while preventing bearing damage and unscheduled turbine downtime.

In single-line lubrication systems, a central pump station precisely delivers lubricant to each individual lubrication point by means of a single supply line to specialised metering equipment.

They are suitable with small-to-medium line lengths and a range of lubricants, including grease up to NLGI 3, oil, and fluid grease. They can service a single machine or several zones on a single machine.

27265 Type 8 Webbing 1 23/32 inch Yellow. 27265 Type 8 Webbing - Available in varying colors and widths from TN Webbing Products.

8613869596835

8613869596835