28Watt - 28 watt

Chromium steel is the most common material used to produce precision load-bearing components for ball bearings, and it offers a cost-effective alternative to stainless steel. Although chromium steel is less resistant to corrosion, it is durable and can still resist corrosive factors in certain environments.

Application environment: Determine potential sources of contamination and other external particles in the application environment of 6204 bearings. Depending on environmental conditions, choose open, metal shielded or rubber seals to provide appropriate protection.

The rolling mill is an indispensable equipment in steel production. It is mainly used to continuously press and stretch the steel billet to finally obtain the required plates, pipes and other products. In the rolling mill, the 6204 bearing plays an important role as an important supporting component.

Versatility and customization: a Lincoln grease pump has various configurations and voltage options to match specific lubrication needs, allowing businesses to tailor the system to their requirements

9. Maintain good working condition: The normal working condition of the 6204 bearing is the key to ensuring its service life, so attention should be paid to discovering and solving abnormal situations in time.

Maintenance requirements: Consider your bearing maintenance needs. Open bearings require regular cleaning and lubrication, while metal dust boots and rubber seals can greatly reduce the need for maintenance.

6204 bearing is a common and widely used bearing model. Understanding its bore, outside diameter and width dimensions is critical to selecting the appropriate bearing. Choose the right size for your application based on your application requirements, load, speed, temperature and quality standards to ensure good performance and reliability.

In the steel industry, 6204 bearings are also a commonly used component. It can be applied to various steel processing equipment, such as rolling mills, drawing machines, extruders, etc.

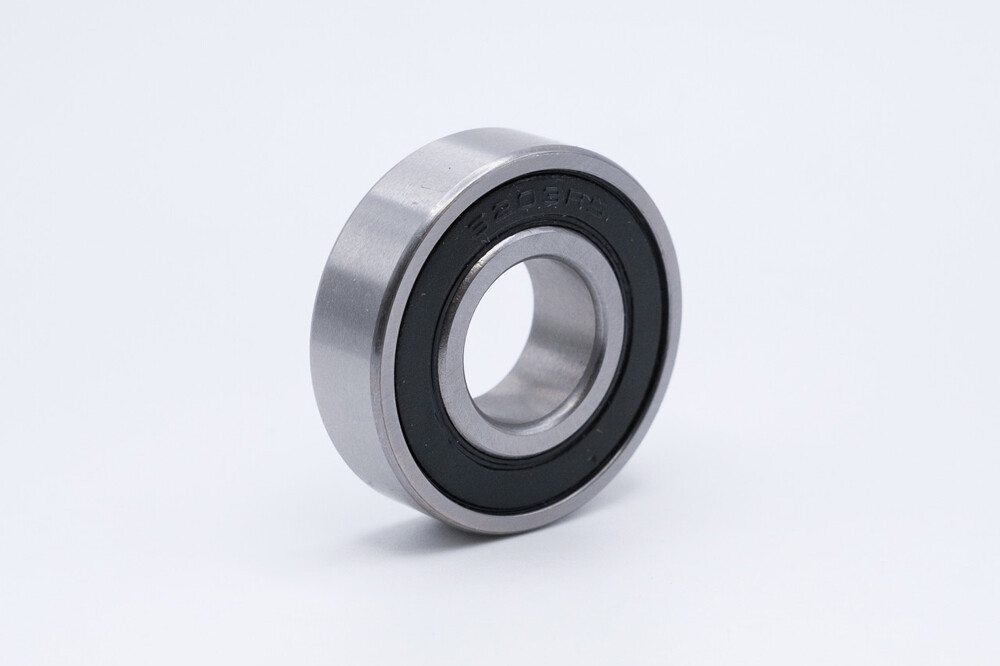

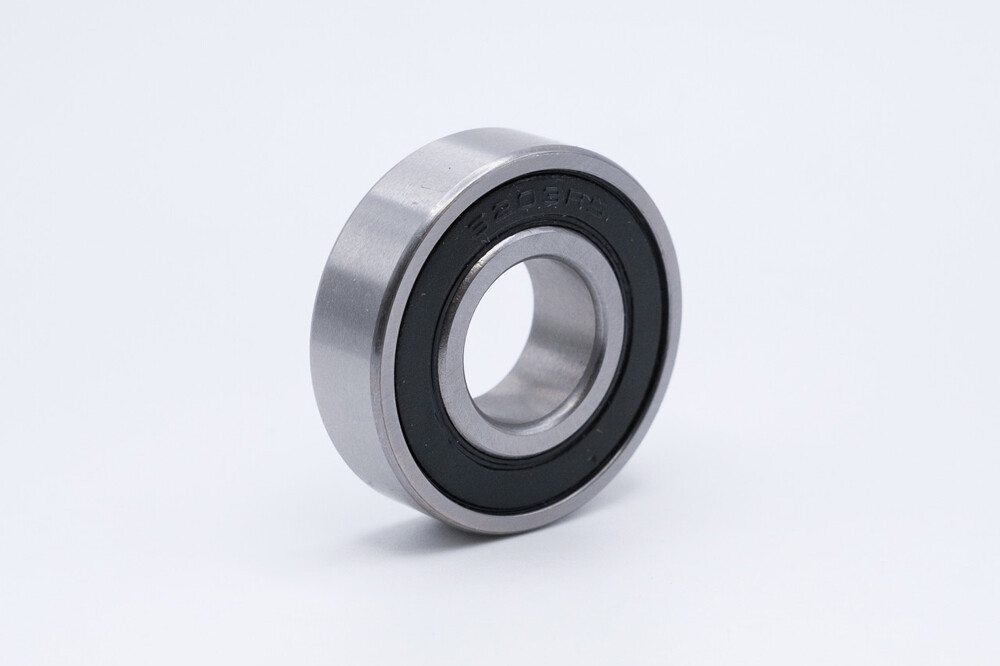

6204 bearing is a common deep groove ball bearing, which consists of inner ring, outer ring, steel ball, cage and other components. It has an inner diameter of 20 mm, an outer diameter of 47 mm, and a thickness of 14 mm. This size design allows 6204 bearings to be used in machines of different sizes.

2. Bearing usage environment: 6204 bearings are suitable for working environments with temperatures ranging from -30°C to +120°C. If they exceed this range, their service life may be affected.

7. Pay attention to the storage method: If the 6204 bearing is not used for a long time, please pay attention to the storage method to avoid moisture, deformation, etc., which will affect its service life.

The Lincoln P203 grease pump is a versatile, compact, and cost-effective solution that can handle up to 150 grease points, depending on the line length. This pump consists of a housing with an integrated motor, a reservoir with a stirring blade, a pump element with a pressure relief valve, a filling nipple, and automatic connection parts. The P203 grease pump can be upgraded to accommodate three pump elements and is compatible with low-level controllers, offering enhanced control and flexibility.

Whether it is industrial machinery, equipment or household appliances, 6204 bearings are essential components. They are used to support rotating shafts, carry loads, reduce friction and provide smooth movement. Various sectors of the manufacturing industry, such as wind power generation, food processing, printing machinery, etc., rely on high-quality bearings.

– High temperature resistance: 6204 bearings use special high-temperature grease inside, which can operate in high-temperature environments and maintain good lubrication effects. High temperatures will be generated during the steel production process, and 6204 bearings adopt a special heat treatment process to maintain stable operation in high temperature environments and are not easily damaged.

Ancotech is a trusted Lincoln Industry partner, Pressol partner and Graco partner, providing you with a comprehensive range of products and solutions. We not only import and offer their products, you can also use our reliable services for advice, installation, maintenance and repairs to keep your operations running as smoothly as possible. As a specialist in automatic lubrication systems we offer multiple machinery and equipment lubrication solutions such as:

Steel balls are spherical components used as rolling mechanisms in rotating moving parts such as bearings, tools, and wheels. There are many specifications and sizes for various purposes. Steel balls play the most crucial role in performing functions. The most important purpose is that it represents the importance of the rolling and rotational aspects of the bearing. Without it, the bearing may not rotate in any direction.

– Good sealing: A large amount of dust and liquid will exist during the steel production process, and the 6204 bearing uses high-quality seals, which can effectively prevent dust and liquid from entering the inside of the bearing and extend its service life.

Bearing cage is simply called a bearing separator or cage; it is the component in a ball bearing that separates the balls, rollers, or needle rollers and keeps them evenly spaced radially, and holds the bearings together. The cage holds the balls in uniform rings so that they are equally spaced within the bearing. It can be manufactured into a variety of shapes and developed using low-friction materials, allowing the ball to continue rolling efficiently. The materials of bearing cages include: steel bearing cages, ceramic bearing cages, plastic bearing cages, etc.

8. Precautions for use: During use, pay attention to prevent the bearing from being affected by external forces such as impact and vibration to avoid damage.

6204 bearings usually consist of an inner ring, an outer ring, ball elements and a cage. The grooves in the raceway are slightly larger than the radius of the steel ball. Since the steel ball and the raceway are in point contact, the 6204 bearing can bear both axial loads in both directions and radial loads. Generally, they are usually used in pairs to minimize the internal axial force caused by the load and mainly bear the radial load.

4. Economical and practical.Compared with other types of bearings, 6204 bearings have lower cost and long service life. This makes it one of the most economical and practical options in the steel industry.

Looking to order a Lincoln grease pump that meets your requirements? Place an order on our website, we ship internationally. Do you have any specific questions or service-related issues? Please contact us by filling in our contact form or by calling +31 (0)72-561 65 53.

In need of a Lincoln automatic grease pump? An efficient and easy to use lubrication system is vital to boost productivity and ensure that your machinery functions properly. Lincoln Industrial is a trusted brand that offers a wide range of high quality automatic greasing systems. With their advanced technology and robust designs, Lincoln grease systems are the go-to solution for various industries such as general manufacturing, construction and the automotive industry. Explore the different types of automatic grease pumps and place an order.

4. Avoid overload operation: Although 6204 bearings have a certain load-bearing capacity, long-term overload operation will accelerate their wear and affect their service life.

1. Pay attention to the installation position of the bearing: 6204 bearings are usually used in automobiles, motors and other equipment. Pay attention to their position during installation to ensure that they can withstand the corresponding load.

Outer diameter of the 6204 bearing: The diameter of the bearing outer ring is 47 mm, ensuring that your application space can accommodate this size of diameter.

Width of 6204 bearings: The distance between the inner and outer rings of the bearing is 14mm, make sure this size is appropriate for your application to ensure correct installation and operation.

Ceramic ball bearings are made of ceramic materials. The inner ring, outer ring and balls are made of silicon nitride (Si3N4) or zirconium oxide (ZrO2). It has higher hardness and better elasticity than chromium steel bearings. In addition, ceramic ball bearings can run completely dry without lubricating oil, have excellent corrosion resistance, can run in concentrated acids, and will not corrode when fully immersed in seawater. Also suitable for temperature changes, ceramic bearings have a much longer life cycle than steel bearings.

The Lincoln QLS 401 automatic grease pump is a reliable and fully monitored lubrication system suitable for up to 18 lubrication points. Designed for multi-line and progressive systems, this pump ensures continuous lubrication with or without a low-level indicator. It comes in various voltage options, including 12V, 24V DC, and 120V, 230V AC, and features an integrated controller for efficient working hour management.

– Low friction coefficient: The 6204 bearing adopts a spherical roller structure inside, with only point contact between the inner and outer rings, resulting in small friction and smooth operation.

1. Simple structure and easy to install.The 6204 bearing structure is relatively simple, so it is easier to install. This is very convenient for workers in the steel industry and can save a lot of time and energy.

3. Good wear resistance.Due to the harsh working environment in the steel industry, the wear resistance of bearings is very high. The 6204 bearings are made of high-quality steel and have been precision processed to have excellent wear resistance. Even when used under harsh conditions such as high temperature and high pressure, it can maintain good operating conditions.

For high-pressure applications requiring multi-line and progressive systems, the Lincoln P215 centralized pump is the ideal choice. With 15 adjustable pump elements, this pump ensures precise and efficient grease lubrication. It can be used as a direct supply grease pump or as a centralized automatic greasing system catering to diverse industrial requirements.

2. Strong carrying capacity.6204 bearings use rolling elements as load transmission elements and have stronger load-bearing capacity than other types of bearings. This makes it widely used in the steel industry and can withstand the operating loads of a large number of heavy equipment.

Durability and reliability: Lincoln Industrial is known for producing pumps built to withstand demanding industrial environments, ensuring long-lasting performance and minimal downtime

Since steel production requires high equipment accuracy and stability, higher requirements are also put forward for 6204 bearings. In order to ensure production efficiency and product quality, many steel companies choose to use high-quality 6204 bearings, such as German FAG, Japanese NSK and other brands.

6204 bearings are widely used in automobile engines, transmissions, wheels, electric motors, etc. 6204 bearings are capable of withstanding high-speed rotation and loads, providing smooth operation and durability, ensuring vehicle reliability and performance.

Once you have ordered the Lincoln grease pump or other lubrication system that fits your needs, we guarantee a quick delivery. For both domestic and international orders we ship from our own warehouse in The Netherlands using DHL’s services. In case you want to know whether your desired product is available, our website displays the current stock due to our real-time stock system. Moreover, our team of VCA certified professionals will gladly provide assisting and installation of the automatic greasing systems.

Continuous lubrication: Lincoln grease systems, whether multi-line or progressive, ensure a steady supply of lubricant, maintaining optimal performance and extending the lifespan of machinery and equipment

10. Sealing performance inspection: For 6204 bearings that need to be sealed, their sealing performance should be checked regularly to ensure their normal operation.

– High load capacity: 6204 bearings are made of high-quality steel, have high strength and hardness, can withstand large radial and axial loads, and can stably support heavy objects during the steel production process to ensure smooth production.

As an integral part of mechanical operation, 6204 bearings play an important role. First, it reduces friction and resistance, making the machine run smoother. Secondly, it can support lifting objects and rotating parts, playing a stabilizing role during machine operation. In addition, 6204 bearings can also resist vibration and impact, ensuring the safe operation of the machine.

6204 OPEN type bearing cover is a coverless design, allowing the internal components of the bearing to be exposed to the external environment. This design makes the bearings susceptible to contamination from dirt, dust, and other external particles. Therefore, type 6204 OPEN bearings are suitable for clean environments or applications that require regular cleaning.

Investing in a reliable automatic grease pump is crucial for optimizing lubrication processes and ensuring the longevity of your equipment. With Lincoln automatic lubrication systems, you can achieve continuous central lubrication, customization options, enhanced control, cost-effectiveness and durability. As a Lincoln grease pump distributor, we are your one-stop solution, providing quality products and excellent service.

First of all, in the main transmission system of the rolling mill, the 6204 bearing is installed between the motor and the reducer to play a connecting and supporting role. Secondly, in the roller transmission system, 6204 bearings are installed on the rollers, which can withstand large radial and axial loads and keep the rollers running smoothly. In addition, in the lubrication system, 6204 bearings also play an important role in ensuring the smooth delivery of lubricating grease to various parts.

As an indispensable and important component in the steel production process, 6204 bearings have the characteristics of simple structure, long service life and strong load-bearing capacity, and play an important role in the steel industry. Therefore, when selecting a suitable 6204 bearing, it is recommended to choose according to the specific production needs and use environment to improve steel production efficiency. Finally, as the editor of the website, thank you very much for reading this article and hope it can bring you some useful information. If you have any other questions or suggestions about this article, please feel free to contact me and we will be happy to answer your questions. At the same time, you are also welcome to pay attention to our website to obtain knowledge about industrial products and related industry trends.

Enhanced control: with integrated controllers and optional low-level indicators, the lubrication system provides improved monitoring and management of lubrication processes

Extensive industry applications: from automotive manufacturing to printing and publishing, automatic greasing systems find applications in a wide range of industries, providing reliable lubrication for various materials and processes

6204 bearings are widely used in various motors, including household appliances, industrial motors, power tools, etc. The high-speed operation and durability of bearings make them important components of electric motors, ensuring smooth operation and high efficiency.

In this article, Aubearing will help you understand the definition and function of 6204 bearing, structure and characteristics analysis, usage precautions, and its application cases in the steel industry. At the same time, Aubearing will also share how to choose suitable 6204 bearings to improve steel production efficiency. Let us uncover this mysterious bearing together.

5. Prevent foreign substances from entering: During use, pay attention to prevent dust, moisture and other foreign substances from entering the inside of the bearing, so as not to affect its normal operation.

Accuracy and speed requirements: Consider the application accuracy and speed requirements of 6204 bearings. Open bearings are generally suitable for low precision and lower speed applications, while metal shields and rubber seals provide a higher level of protection and are suitable for medium to high precision requirements.

6204 OPEN, 6204 ZZ and 6204 RS are different bearing cover patterns that provide varying degrees of protection and support. Depending on your application environment, accuracy and speed requirements, and maintenance needs, choose the appropriate cover method to ensure normal operation of the bearing and extend its service life.

6204ZZ means that the outer cover has a metal shield. The metal shield effectively blocks the entry of dust, contaminants and other external particles while retaining lubricant within the bearing.

For the 3D drawing, we prefer to STEP, IGS or X_T format. The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

3. Regularly check the lubrication condition: Since the 6204 bearing needs lubrication when working, it is necessary to check the lubricating oil condition regularly to ensure its normal operation.

Steel ring. Its main purpose is to basically act like a path, allowing the balls inside the ball bearing to slide without friction. Simply put, ball bearings require a race to control the individual balls, and it provides a fixed path for the balls to roll.

6204 bearings can withstand large radial and axial loads. Due to its excellent performance characteristics, 6204 bearings are widely used in various mechanical equipment, playing an indispensable role in fields ranging from the automotive industry to manufacturing, from agricultural machinery to electrical industry, from compressors to water pumps. Their high-speed operation, durability and reliability make them the first choice in these industries. Especially in the steel industry, it can play an important role in steel production, processing, transportation and other links, as well as in the use of steel machinery.

6204 RS means the outer cover uses a rubber seal. Rubber seals effectively block the entry of moisture, dust and other contaminants, providing enhanced protection. This type of sealing is often used in harsh environments and applications that require stringent protection.

The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

Cost-effectiveness: by automating the lubrication process, automatic grease pumps eliminate manual labor, reducing downtime, and minimizing maintenance costs

6. Regular cleaning and maintenance: In order to ensure the normal operation of 6204 bearings, it is recommended to clean and maintain them regularly, and replace seriously worn parts in time.

From harvesters to irrigation equipment, 6204 bearings play a vital role in agricultural machinery. They are able to withstand harsh environmental conditions and high loads, allowing agricultural machinery to operate smoothly and improve work efficiency.

Stainless steel 6204 bearings offer several significant advantages. Because stainless steel in particular has greater chemical and corrosion resistance, as well as better stability in high-temperature environments. Stainless steel bearings have the same deep grooves and tight fit between raceways and balls as standard deep groove ball bearings made of carbon chromium steel.

8613869596835

8613869596835