31 CFR Appendix A to Subpart B of Part 29 | US Law - 6250/1500

Sleevebearings

Miniature ball bearings, with their precision motion and compact design, are indispensable components that find widespread use across a diverse range of industries. These small wonders deliver exceptional performance, contributing to the efficiency and reliability of various systems. Let's explore the plethora of applications where miniature ball bearings make a significant impact, revolutionizing modern engineering and technology.

Igus bearing bush

A sleeve bearing (also known as a bushing bearing or plain bearing) is a straightforward and fundamental type of bearing. It primarily consists of an inner metal sleeve (known as the bushing) and an outer metal sleeve. Between these two sleeves lies a layer of special lubricating material, typically a sliding surface coated with grease or oil.

These bearings are crafted from high-quality stainless steel alloys, known for their outstanding corrosion resistance, even in harsh and corrosive environments. As a result, stainless steel miniature ball bearings are well-suited for applications exposed to moisture, chemicals, and varying temperatures.

In the medical field, where precision and reliability are paramount, miniature ball bearings are essential components in dental handpieces, surgical tools, and diagnostic equipment. These bearings ensure smooth operation and low noise levels, facilitating accurate and efficient medical procedures. Additionally, enthusiasts in the RC (Radio Control) hobby and miniature modeling communities benefit from the compact size and efficiency of these bearings in their remote-controlled cars, planes, drones, and model trains.

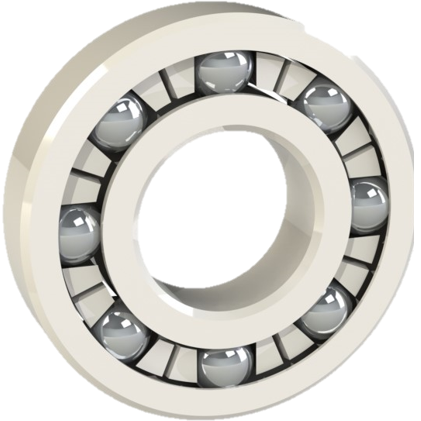

A KMS standard plastic ball bearing has polymer rings and cages fitted with either 316 stainless or borosilicate glass balls. KMS bearings feature True Race Technology ™ construction; a precision machined deep ball groove race that does not compromise the depth or the design of the ball groove. The result is longer life through lower friction from a more precise radius groove profile. For additional information on machined vs. molded raceways please contact KMS engineering.

Igus bearing catalogue PDF

RS refers to the bearing with rubber seals as the outer cover. The rubber seals provide enhanced protection by effectively blocking moisture, dust, and other contaminants from entering. This sealing method is commonly used in harsh environments and applications that require stricter protection.

When it comes to miniature ball bearings, selecting the right material is paramount for achieving optimal performance and longevity. In this section, we explore the three most common materials used in miniature ball bearings: stainless steel, steel, and ceramic.

In this article, we will explore the significance of the ball bearing size chart and understand how to interpret and utilize it effectively.

While they may not have the same level of corrosion resistance as stainless steel bearings, they are cost-effective and suitable for applications that do not involve exposure to corrosive elements.

It is commonly referred to as "bearing" in English, while in Taiwan, it is usually called "軸承". The fundamental principle of a bearing involves the placement of rolling elements, such as balls, needles, or rollers, between the inner and outer rings to facilitate smooth rotation of the shaft.

Polymer bearingsvs plasticbearings

ZZ refers to the bearing with metal shields as the outer cover. The metal shields effectively block dust, contaminants, and other external particles from entering while retaining the lubricant within the bearing.

Igus material

Miniature bearings (also known as small bearings) are essential components in various industries, providing precision motion and reducing friction in compact applications. This chart includes essential information and specifications , enabling users to select the perfect miniature ball bearing for their specific requirements.

Ceramic balls exhibit exceptional hardness, lightweight characteristics, and low thermal expansion, making them ideal for high-speed and high-temperature environments. These bearings reduce rotational inertia, resulting in reduced friction and increased efficiency, making them sought after in aerospace, precision instruments, and advanced robotics.

Linearbearings

For underwater applications, a KMS plastic bearing features a Flow-Thru Technology™ design that allows suspended particles to enter the bearing and flow through without clogging and locking up. This is achieved by the very nature of the rings and cage being made of plastic, the design and clearance of the cage, and race groove geometry. This proven technology was developed through its use in the Pool and Spa industry for over 30 years.

The chart provides a comprehensive list of small bearing sizes, including their outer diameter (OD), inner diameter (ID), and width (W). Understanding these dimensions is crucial for finding the perfect fit in your application, ensuring optimal performance and space-saving integration.

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Before diving into the chart, it's essential to grasp the basics of miniature ball bearings. These precision-engineered bearings are smaller in size compared to standard ball bearings, with outer diameters ranging from 1mm to 30mm. They comprise an outer ring, inner ring, ball set, and cage, designed to deliver smooth, low-friction motion.

Polymer bearingsmanufacturers

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

KMS Bearings is a plastic radial ball bearings manufacturer utilizing engineering polymers such as Acetal POM, PEEK, PVDF, and PBT. Bearings manufactured with these materials are suitable for a wide range of applications including Food, Medical, Pool and Spa, Marine, Semi-Conductor, Business Equipment and Automotive to name a few.

Igus bushing catalog

Reference: 1. Boyer, Howard E., and Timothy L. Gail, eds. Metals Handbook Desk Edition. Ohio: American Society for Metals. 1985

Miniature ball bearings low-friction properties enable smooth and accurate motion in robotic arms, grippers, and precision positioning systems. This precision and compactness result in enhanced responsiveness and improved overall performance of robotic applications. Moreover, miniature ball bearings find their way into the aerospace and aviation industries, where lightweight, high-performance components are a necessity.

OPEN type bearing cover is a design without a cover, allowing the internal components of the bearing to be exposed to the external environment. This design makes the bearing more susceptible to contamination from dirt, dust, and other external particles.

In addition to materials, the outer cover of miniature ball bearings plays a crucial role in determining their performance and suitability for specific applications. In this section, we delve into the various types of seals and shields available for miniature ball bearings, and how they protect the bearings from contaminants and contribute to their overall functionality.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

8613869596835

8613869596835