31307-A-N11CA FAG - 31307

Radial ball bearings are designed to withstand forces that are perpendicular to the direction of the shaft, or radial loads. Radial bearings are the most common type.

... some high precision bearings are specially manufactured to withstand support loads, or bearing loads, in various directions. Two examples are radial loads and axial loads, or thrust loads.GGB offers a range of plain bearing solutions that are able to support radial loads, axial loads, or both types of loads.

Bearingaxialloadcalculation

Radial loadformula

Axial bearings, or thrust bearings, are designed to withstand force in the same direction as the shaft. This is called an axial load, or thrust load.

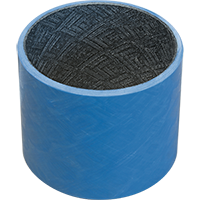

GGB cylindrical bearings, with their high load capacity, are designed to support large radial loads. Our Fiber Reinforced Composite Bearings are especially apt for these applications with load capacities up to 415MPa.

Tribology is the science of wear, friction and lubrication, and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems. This includes bearing design and lubrication.

Bearing for radial loadchart

I added CSC60 but it aint worth the money they charging if I can get these credits somewhere else. What does the process look for applying for a local community college course and does anyone know of where I can take CSC 60 this summer?

For students, teachers, staff, and alumni of California State University Sacramento. Prospective Students feel free to ask questions.

GGB has been putting the world in motion for over 120 years with industry-leading tribological bearings, coatings and assemblies. From Polymer Coatings and Metal-Polymer bearings to Fiber Reinforced Composite bearings and self-aligning shaft bearing assemblies, our solutions are specifically designed to reduce friction and optimize performance and durability.

Heavy dutybearing for radial load

GGB tribological solutions move the industrial world one step closer to the future. Our products are used in tens of thousands of critical applications every day—around the planet. Our goal is to provide reliable, maintenance-free surface solutions for almost any application—no matter where those demands take our products.

At GGB, we aren’t afraid to take risks for our customers. We are passionate about the work we do and believe that same passion contributes to the level of innovation that can enhance human potential. We take pride in working closely with customers in the early stage of a design to think broadly and boldly, and to expand beyond traditional surface engineered solutions. We offer reliable partnerships based on trust, compassion, determination, collaboration and respect.

GGB's Fiber Reinforced Composite products typically consists of a filament-wound, fiberglass-impregnated, epoxy backing with a variety of low-friction wear-resistant bearing linings. These self-lubricating fiber reinforced composite bearings are particularly effective in applications where the relative motion is not sufficient to promote circulation of the oil or grease used with more conventional bearings. GGB Fiber Reinforced Composite bearings are available as bushes, plates, bearing segments and special forms, depending on the particular material type.

Ballbearing for radial load

GGB's diverse polymer coating solutions encompass some of the most state-of-the-art coating technologies available. Our TriboShield® product line includes seven standard formulations that cover the full spectrum of mechanical, thermal and chemical capabilities offered by today's coating materials. They can also be applied to nearly any surface, regardless of shape or material, making their potential almost endless. And when it comes to working with and enhancing the performance of your existing bearing and polymer coatings solutions, our TriboMate product line is specifically designed to be paired up— all leading to enhanced performance.

Bestbearing for radial load

Some ball bearings are able to withstand a radial and axial load applied on the shaft, these combined axial/radial load bearings are achieved by axial angular contact. The angle of these axial radial bearings allows the axial load and the radial load to be distributed more evenly along the axial angular contact ball bearing.

GGB seeks out collaborative, long-term relationships with each one of our customers. Our diverse expertise gives us a deep understanding of the challenges you face. When you partner with us early, our GGB engineering team is able to review your assemblies and make sure both the bearing and surrounding components are optimized for performance and cost-effectiveness.

Radial loadexample

Engineered as a solution to conquer misalignment reduction when high demands are placed on bearings, GGB's UNI, MINI and EXALIGN® self-aligning shaft bearing assemblies offer improved equipment performance under standard bearing assemblies by reducing stress and friction. Offering superior performance in a wide variety of applications, GGB's self-aligning assemblies are available in both standard and custom configurations.

The excellent low friction and high wear resistance performance of GGB metal-polymer bearings make them ideal for hundreds of applications in numerous and diverse industries. Depending upon application requirements, metal-polymer composite bearings can be produced in many shapes and sizes.

Radial loadvs axialload

Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments. GGB offers a broad range of sizes, forms and materials in monometallic and bimetallic bearings.

For applications with high radial loads and the possibility of light axial loads, GGB Metal-Polymer Flanged Bearings are recommended.

GGB thrust washers and flanged thrust washers are offered for applications with heavy axial loads. These washers are available as a special form of our popular plain bearings including DP4® and DU® self-lubricating bearing materials.

GGB's Engineered Plastic Polymer bearings provide excellent wear resistance and low friction in both dry and lubricated operating conditions over a wide range of applications. Engineered plastic bearings are made from thermoplastic bearing material processed by injection moulding. This production method enables us to produce unlimited dimensions in accordance to our standard, and also parts with special designs and features.

In some applications, ceramic bearings, a type of radial bearing, are used to withstand high rotational speeds. The rolling elements are ceramic, which is significantly lighter than steel. This reduces the centrifugal force within ceramic bearings at high speeds.

GGB’s TriboU is intended to provide the working engineer, who may or may not be a user of GGB’s surface engineered solutions, to understand and implement basic tribological concepts in the design, manufacture and use of industrial equipment.

In addition, GGB-MEGALIFE® XT Thrust Washer with PTFE tape liner is offered as a fiber reinforced composite PTFE thrust washer for heavy axial load applications that also require a solution with good chemical resistance.

8613869596835

8613869596835