6001-2RSR FAG New Single Row Ball Bearing. Size: ... - 6001 bearing dimensions

انواع شافت

Prevent gear damage efficiently: The innovative lubricating pinion from Liebherr reliably prevents wear and helps to avoid bearing damage.

Protect the environment and save money: At our certified locations, we offer you the opportunity to restore your slewing bearing to a perfect, functionally-reliable condition at a low cost.

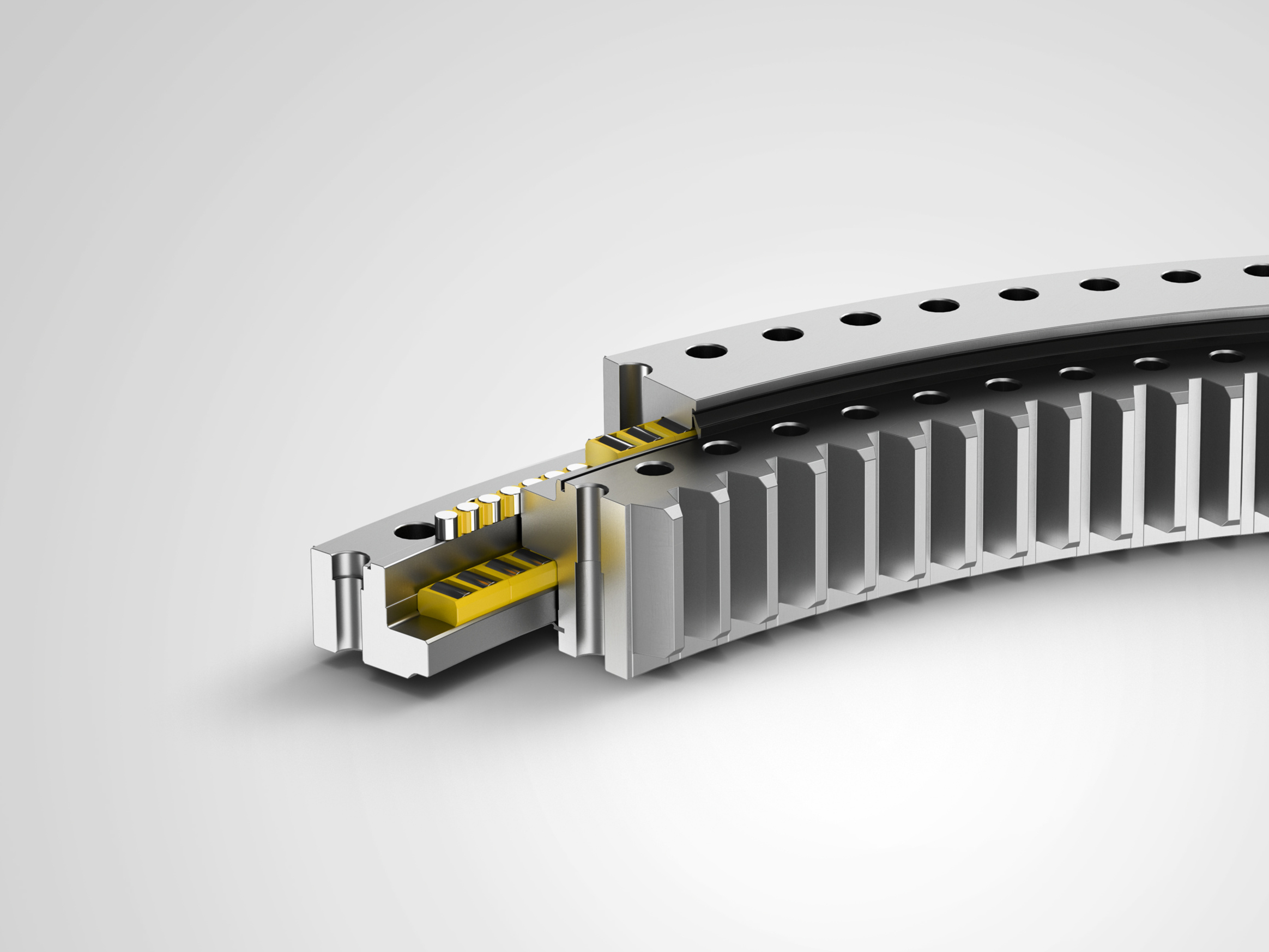

Increase the durability and productivity of your wind turbine with Liebherr blade bearings. In addition to conventional single and double row four-point bearings, Liebherr also offers 3-row roller blade bearings. This design offers great potential in terms of dimensioning and load absorption or capacity.

قیمتشفتck45

Robust and low-maintenance: Liebherr pitch drives are particularly durable and outpace most quality standards. With their resilience and long maintenance intervals, they guarantee permanent availability and the best possible energy yield from your wind turbine.

Depending on the type of wind turbine, triple-row roller bearings, double-row tapered roller bearings or single-row tapered roller bearings are used as main bearings. While the roller bearing leads to lower stresses in the adjacent construction, the tapered roller bearing is particularly attractive because there is no play, which helps keep functioning of the rolling element optimal. We would be happy to help you the best component.

Benefit from our global service offers as well as proven logistics and storage concepts available for immediate use in the event of damage.

شافت در مردان

With our worldwide production network, the availability of our components and services is optimal, with guaranteed short delivery times and providing you with local contacts only a stone’s throw away. This decreases transport costs, protects the environment and guarantees top-notch service. Together, we can contribute to low-emission power generation.

We offer you an all-inclusive package from one single source. Let us win you over with our products, high flexibility and efficient processes.

Keep the nose in the wind: Azimuth (yaw) drives optimally align your nacelle with the prevailing wind direction. With yaw drives from Liebherr, you are choosing high-quality, durable and low-maintenance components that extend the service life of your wind turbine.

شفتهارد کروم

Benefit from high quality products and a wide range of unique services. With our balanced price-performance ratio, we always go the extra mile for your success.

We already know tomorrow's requirements, today. With our service offerings, we go beyond the components business and give you the support and flexibility you need to be competitive in the market.

قیمتشفت فولادی

Innovation combined with decades of experience means high-quality solutions and services for your fleet. With our many years of experience in the wind industry, we can support you with the overhaul or replacement of components to ensure high system availability.

شفتترانس چیست

Are you looking to open up new markets quickly and flexibly or expand your production capacity? We can help you achieve it with our Liebherr assembly service, thus releasing you of the need to invest in the capital-intensive construction of your own infrastructure.

فولاد mo40

Liebherr has been further developing its Finite Element Analysis (FEM) of bearings for years. In addition to the bearing, the blade and hub geometry are included in the calculations.

As a reliable partner, we put the longevity of your wind turbine first. This is why we offer spare parts, exchange components, redesign, component monitoring or technical advice and much more. In a nuthshell: We provide the support you need during the entire life cycle of your wind turbine.

Topping off our wide range of offerings, our portfolio also features engineering services, digital monitoring during product evaluation and consulting services.

With components in over 25,000 wind turbines installed worldwide and a vast industry know-how, we offer expert advice, construction and design support for your components and systems. Together we develop the ideas of today and apply them in the products and technologies of tomorrow.

Bearings for blade adjustment are subject to special loads like partial standstill, small rotations, and changing loads.

To increase bearing lifetime and optimize the prevention of idle marks and false brinelling marks, Liebherr co-developed a specialized grease for pitch and yaw bearings:

The global infrastructure of the Liebherr Group offers a wide range of opportunities that are dedicated to serving all of your needs. Our service portfolio includes, but is not limited to the assembly of modules or nacelles. We also develop customer-specific designs to ensure that all components you need are always available.

Be it slewing bearings for blade adjustment or wind tracking, main bearings, slewing drives, hydraulic cylinders or power electronics: We have successfully been supplying wind turbine manufacturers around the world with reliable and innovative components - and have been doing so since 1996.

8613869596835

8613869596835