6002Z (NSK) | Bearing - 6002z bearing

Ball bearings reduce friction by using hardened steel balls between the inner and outer races. This type of wheel bearing is designed to operate at high speeds and control an axle shaft’s thrust movement.

In some cases, you might even need to replace the entire hub because you won’t be able to get to the damaged bearing without disassembling the entire unit.

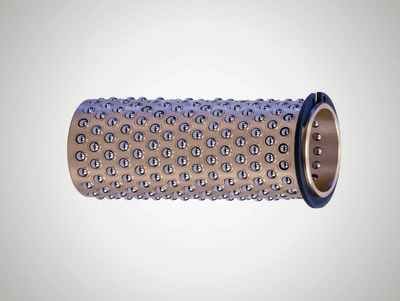

Ball-bearing guides for linear and rotational movements without play for use in all technical areas where reliability and precision are required.

Permanently installed thrust washers on each side and sealing rings prevent impurities from getting into the ball bearing guide.

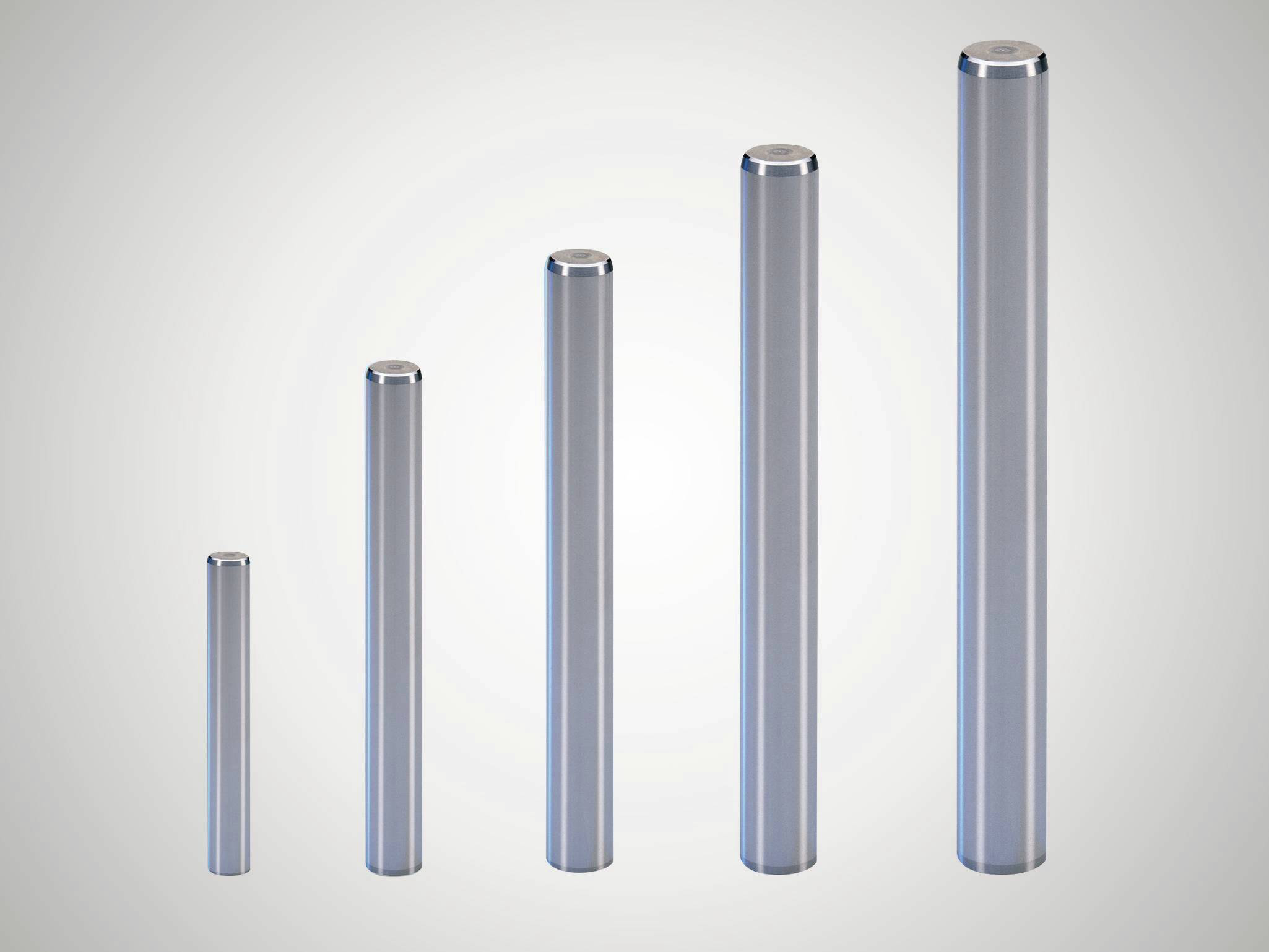

Radial loadbearing types

These anti-friction wheel bearings come in the form of ball, roller, and tapered roller bearings. And while each of them has distinctive features, they all perform the similar task of converting sliding friction into a rolling motion.

Roller bearings have rollers between the inner and outer races to reduce friction. Compared to a ball bearing, this type has a longer contact area to support heavier loads.

Rollers on this type of bearing are secured in a cage between the inner and outer races. The tapered roller bearing is expected to move around the cage freely to allow heat expansion.

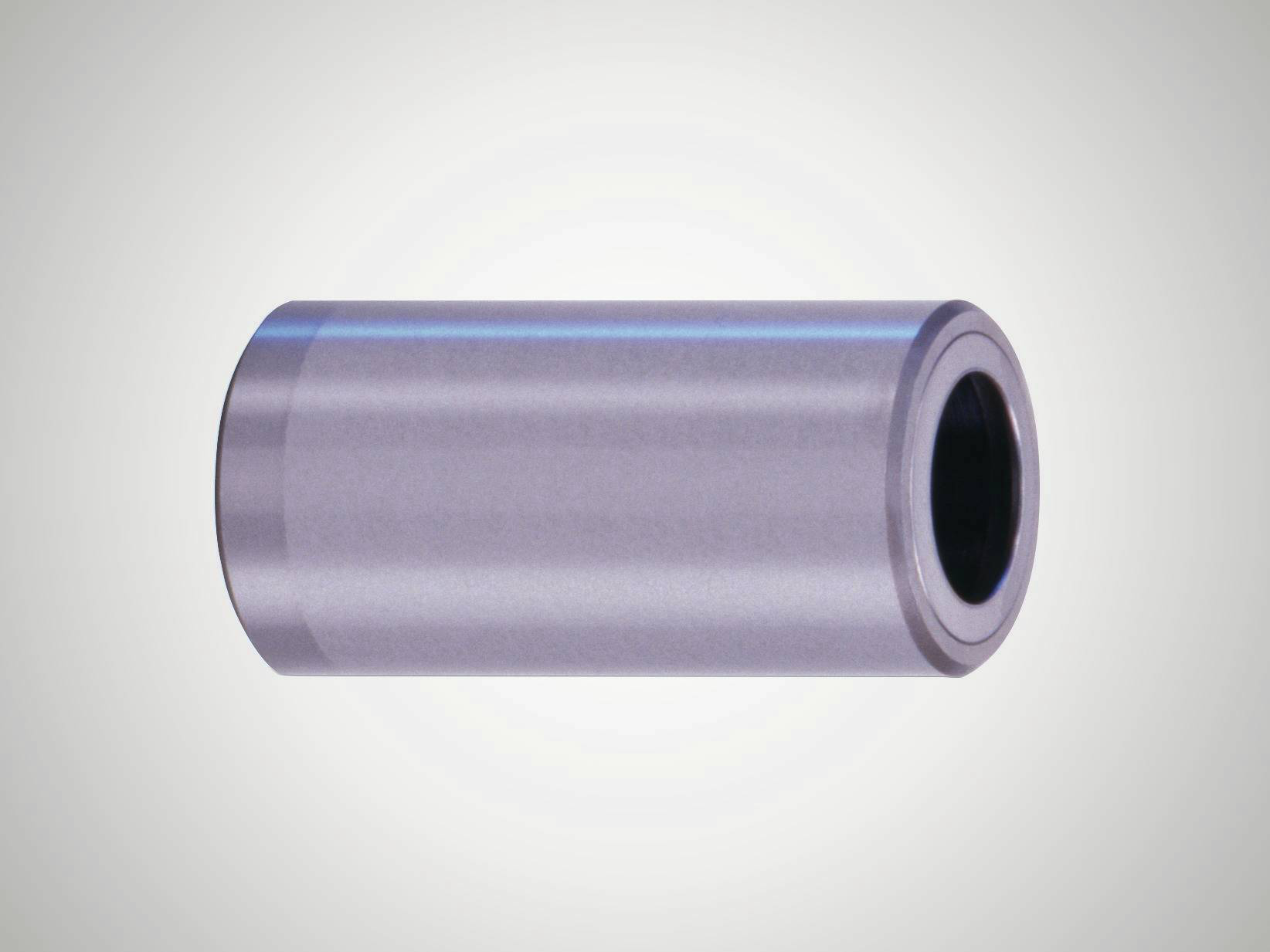

The diagram provided in the overview takes into account the deflection of the rotary stroke bearing when a load is applied, which is determined by the elastic deformation of the balls and the surfaces of the guide bush and guide shaft. The axes of the guide bush and guide shaft are assumed to be rigid; the deflection of the shaft must therefore be taken into account, where applicable.

Radial loadbearing

The tapered roller bearing is the most common type used in vehicles. It is designed to support both radial and axial loads.

Wheel bearings let the wheels rotate while supporting the entire vehicle. These bearings come with rolling parts inside them that help reduce friction.

Radial loadvs axialload

Some vehicles also have needle bearings, which is a type of roller bearing that uses smaller needle rollers. This type is not adjustable because the clearance between the diameter of the straight roller is manufactured into the bearing itself.

A damaged or worn-out wheel bearing can cause the brake rotor to wobble on its axis, which can push the caliper piston into its bore.

Extra sturdy model with scrapers on both sides which reliably prevent impurities from getting in, even in very dirty environments.

How to calculateradial loadon shaft

The radial force PR can also be the resultant of several forces. Depending on the position of the force application point, the forms of the radial load illustrated in the overview are determined.

The cost would be the same as a replacement, as there’s no other way to fix a damaged wheel bearing than to replace it with a new one.

Thrustloadvsradial load

William “Bill” Guzenski has produced hundreds of how-to videos for the automotive community. He’s an ASE Certified Master Automobile Technician, and is affiliated with the Specialty Equipment Market Association (SEMA). He loves attending race events and car shows throughout the country, as well as traveling in his 40-foot motorhome, exploring abandoned mines and ghost towns.

With the different forms of the radial load, the balls in certain sections are charged more than in other sections. The calculation of the loading capacity is based on determining the highest rated radial force P10 of a 10 mm long ball zone. In the following, the correlation between the external load PR or M and the rated radial force P10 are specified for the various forms of the static radial load.

Wheel bearings are generally designed to last the lifespan of your vehicle. However, driving conditions, habits, and other factors can cause them to fail like any other car part.

The finely-ground surface is ideal for high precision ball bearing guides, ensuring smooth running and a long service life of the ball bearing guide.

Once this happens, you’ll notice that the brake pedal feels low or spongy because the piston is traveling farther than normal to apply braking power.

Radialand axialloadon bearing

The elastic deformation of the ball zones causes a deflection of the rotary stroke bearing axis. Depending on the load, the elastic deformation of certain ball zones also differs. For a rated radial force P10, the radial deflection of the axis of the most heavily loaded 10 mm ball zone is defined as the specific deflection A10. This can be used to calculate the expected deflection of the shaft at force contact point A.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Smaller balls used with same shaft diameter compared to type N501. Reduced installation space thanks to guide bushes from the mini series.

Radial loadformula

Because both the bearing and rollers are tapered for this type, it can accommodate more weight. Unlike other types, the load on the tapered roller bearing is directed over the entire length of each roller instead of concentrating on a small spot.

The guide diameter finely honed to ISO tolerance IT 3 guarantees the preload of the ball bearing guide in combination with shaft diameter ISO-h3.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication. Read our full disclaimer here.

The CarParts.com Research Team is composed of experienced automotive and tech writers working with (ASE)-certified automobile technicians and automotive journalists to bring up-to-date, helpful information to car owners in the US. Guided by CarParts.com's thorough editorial process, our team strives to produce guides and resources DIYers and casual car owners can trust.

Radial loadexample

CarParts.com offers a wide variety of wheel bearings from the top manufacturers at different price points. You can purchase wheel bearings individually, in sets of two, or sets of four, depending on your needs. Our parts are shipped from strategically located warehouses, so you won’t have to wait a long time for your part to arrive.

Wheel bearings are a crucial component because they let the wheels rotate while supporting the weight of the entire vehicle. When they become faulty, your vehicle’s wheel hubs are going to create noises and vibrations while you’re driving, which can be unnerving. They can fail catastrophically and cause your wheel to seize, which can result in a crash. Replace your faulty wheel bearings immediately with new ones from CarParts.com.

Replace your vehicle’s faulty wheel bearings before they fail. Check out our selection of wheel bearings and shop at CarParts.com today!

Lastly, fatigue or spalling can lead to fractured bearing surfaces and cause the bearing material to break off after some time.

Although there is less friction when using ball bearings, they’re not made to support the same weight as roller bearings.

The balls can move easily without getting lost. The balls are arranged in such a way that they run smoothly and ensure a long service life of the ball bearing guide.

The radial load of a rotary stroke bearing is determined by the position of the application point of the radial force PR in relation to the center of the ball contact length e.

Driving with a bad wheel bearing is never a good idea. Aside from compromising your safety, you also risk damaging other parts of your vehicle, which can lead to costly repairs down the road. In extreme cases, driving with a bad wheel bearing can even cause one of your wheels to fall off while driving.

8613869596835

8613869596835