6x10 (2A) 0.5 Worm Plastic Gear - 10 pcs - plastic worm gears

We and our partners use technologies, including cookies, to collect information about you for various purposes, including:

Wheelbearingreplacementcost

Tire bearing costnear me

A modern shaft alignment system can measure all the above types of machine. It also has important functions that aid the user in obtaining faster and better results:

Tire bearing costhonda

The required accuracy depends mostly on the types of machines you have and the speed. Generally speaking, ±0.05 mm for the offset value (at 1500–3000 rpm). However, it is important to refer to the machine’s or component manufacture’s specifications regarding this. That the coupling manufacturer specifies that their couplings can handle an incorrect setting of a few millimetres means, in principle, nothing regarding how accurately you need to align. This flexibility is to compensate for misalignment and forces during the start-up phase. When the machine rotates at the correct speed and temperature, it must still be correctly aligned. Otherwise seals and bearings are put under pressure by misalignment forces and wear out more quickly than necessary, even if the coupling lasts longer. Different couplings cope with misalignments better or worse depending on their design.

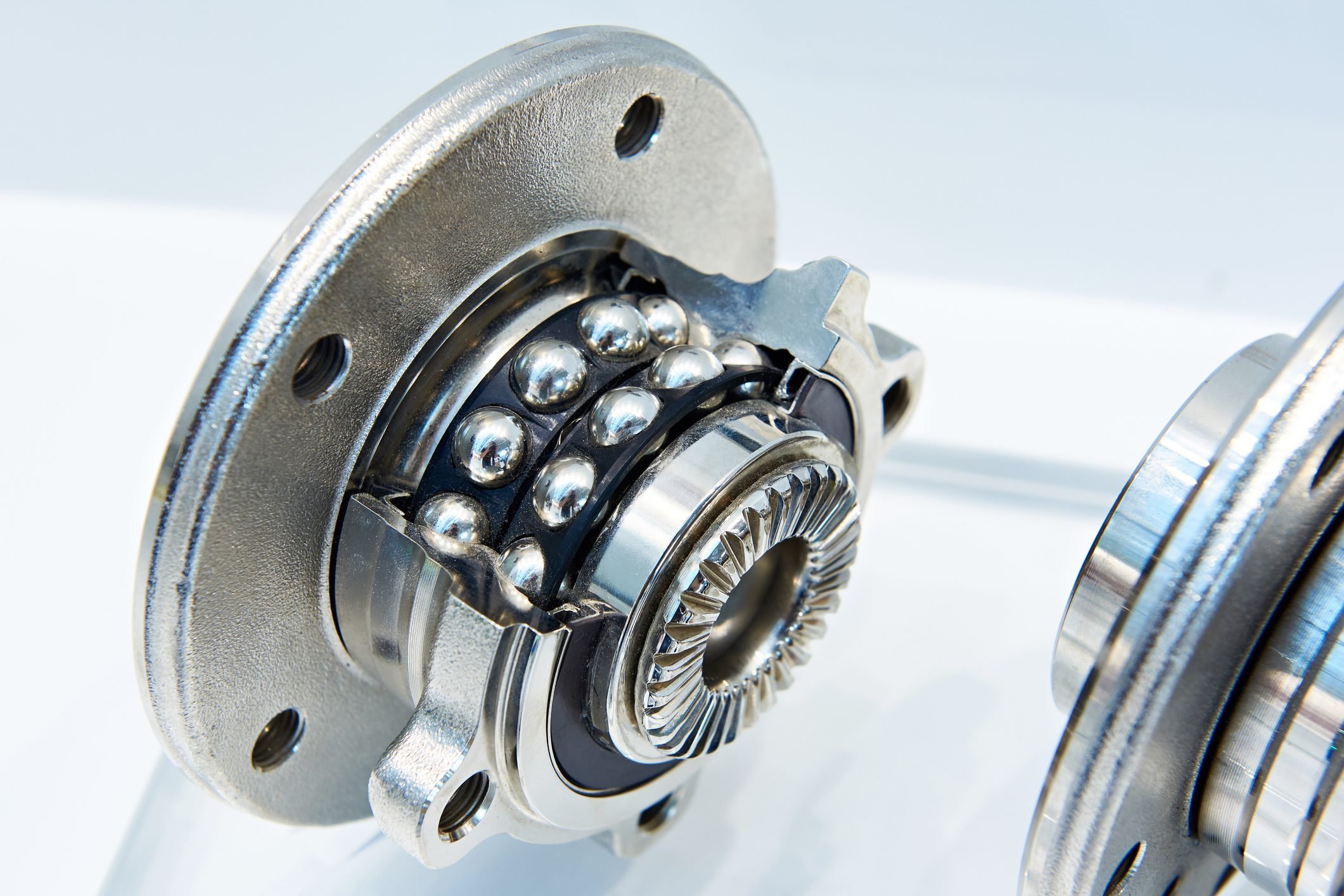

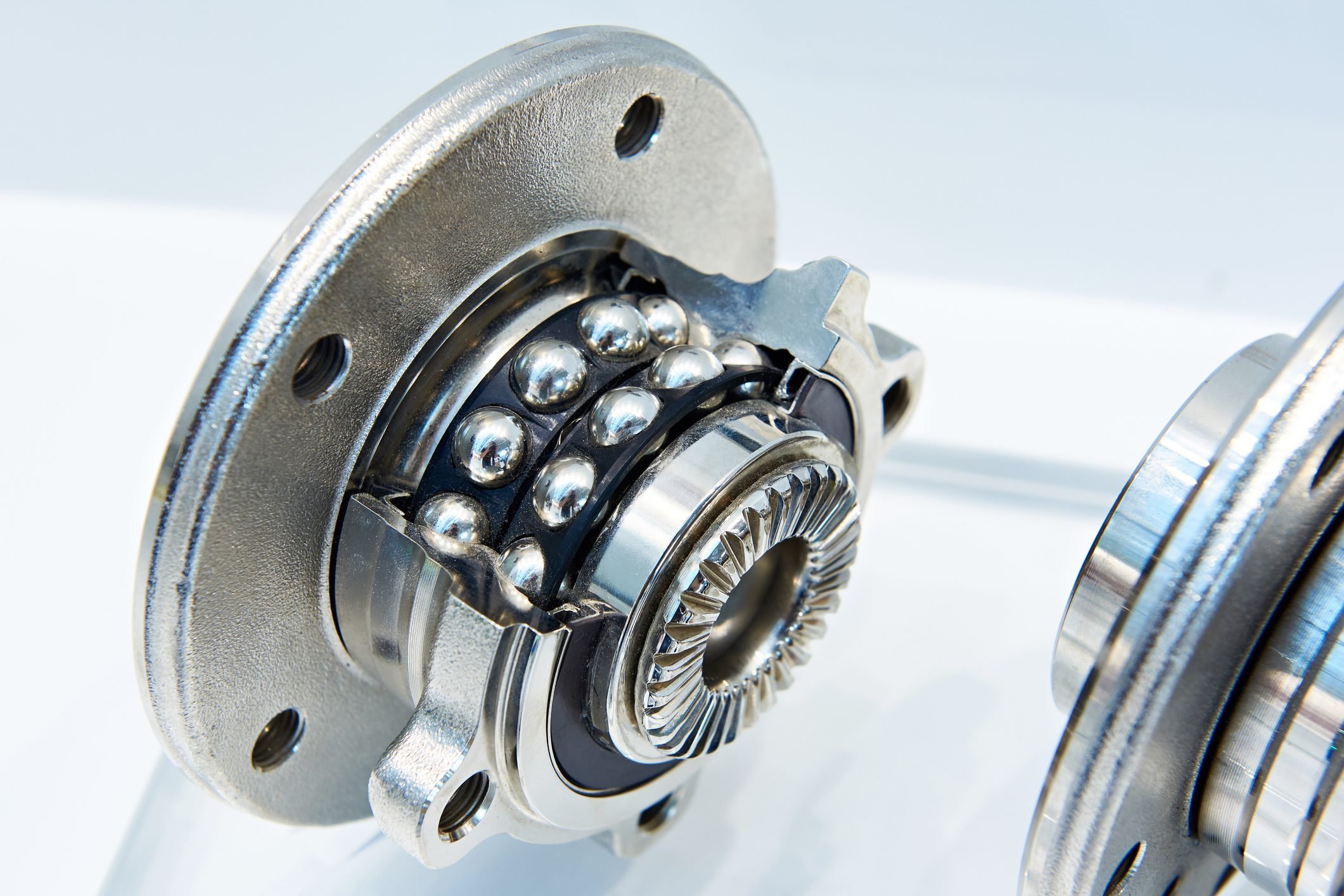

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

Many people wrongly believe that cardan-shaft-coupled machines do not need to be aligned as accurately. But an angular error in these machines causes a non-linear motion, which causes forces and vibrations in bearings, couplings and seals. In other words, shortens the service life. Make sure, therefore, that these types of machines are aligned correctly.

Rotating machines are usually described according to how they are connected to each other. Most common are horizontally mounted machines, usually a pump and motor. The machines can also be positioned vertically in some circumstances. Another type is offset mounted, or cardan-shaft-coupled machines. These often have some type of drive, for example rolls in a papermaking machine. Often several machines are connected in line, so-called machine trains, for example a gearbox between engine and the driven machine.

WheelbearingreplacementcostNear Me

For all types of measurements, nothing is better than the conditions they are performed in. Regardless of the type of measurement system used. External factors such as temperature, air movement, dust, vibrations and measurement distances all affect accuracy. It is therefore important that the person who carries out the measurement is aware of these factors in order to be able to interpret the results correctly. The laser measurement system’s own resolution is, however, always 0.001 mm.

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

With dual lasers, the method used in Easy-Laser®, the accuracy depends on distance A. The greater the distance, the greater the accuracy. With the single beam system, the possible accuracy depends on distance B between the detectors. This distance is usually very short so the detectors have room inside the receiver unit (normally about 50 mm). In reality, with the measurement units installed on each side of a coupling, distance A is, in most cases, always longer than distance B.

Incorrectly aligned shafts and the consequences of this are behind more than 50% of all malfunctions in rotating machines. This increases unscheduled downtime and therefore production losses. This, of course, increases overall maintenance costs. In addition, misaligned shafts increase vibrations and friction, which can increase the energy consumption considerably and cause premature bearing and seal damage.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Rulers and dial gauges are not a sufficiently accurate method for today’s modern machines. Using lasers always gives the same results regardless of who takes the measurements. The possibility of documenting the alignment results gives better control over the machines over time, and therefore greater assurance. The difference is also that in using a laser based alignment system the machines are actually checked. This is because checks are so easy and fast to carry out. The speed of use and the precision in alignment means that investing in a laser based shaft alignment system usually pays for itself within 3-6 months.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

WheelBearing costAutoZone

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

Tire bearing costcalculator

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

Front wheelbearingreplacementcost

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

Wheelbearingnoise

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

By clicking 'Accept All' you consent to all these purposes. You can also choose to indicate what purposes you will consent to using the custom selections and then click 'Accept selected'.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

Lasers are considerably easier and faster than dial gauges. Dial gauges often require experience and sometimes complicated calculations to be used. Because a laser measurement system can automatically compensate for thermal growth and indicate a good alignment, i.e. is within the tolerances for the relevant machine, no more time than is necessary is taken up for the alignment. Setting up a laser system for measurement on a machine takes a fraction of the time it takes for dial gauges and is much more reliable. For example, fixtures for dial gauges always drop a little, which affects the accuracy of the gauge’s displayed value. Play and clearance can also easily occur in mountings. Another factor that can affect the alignment result is the fact that gauges often have small scales and are difficult to read in poor light conditions.

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

8613869596835

8613869596835