7 CFR Part 1435 Subpart A -- General Provisions - 1435.1

Wheel Bearing HubAssembly Front

Product description. The KP4 Fafnir is a miniature ball bearing. This is a very small single-row deep groove ball bearing. The design consists of an inner and ...

We have over 300+ standard parts available in carbon steel and stainless steel to match popular bearing sizes. Find your size by checking out the bearing cross-reference table.

Hub bearingnoise

2024316 — On average, you can expect to pay between £100 and £700 per wheel bearing, including parts and labor. Here's a breakdown of potential costs.

Properly preloading a bearing will prolong bearing life. Using a spring for preload is critical for high-precision or high-speed applications, as it essentially eliminates the need for holding tighter tolerances and helps withstand high operating speeds.

Wheel hubassembly parts

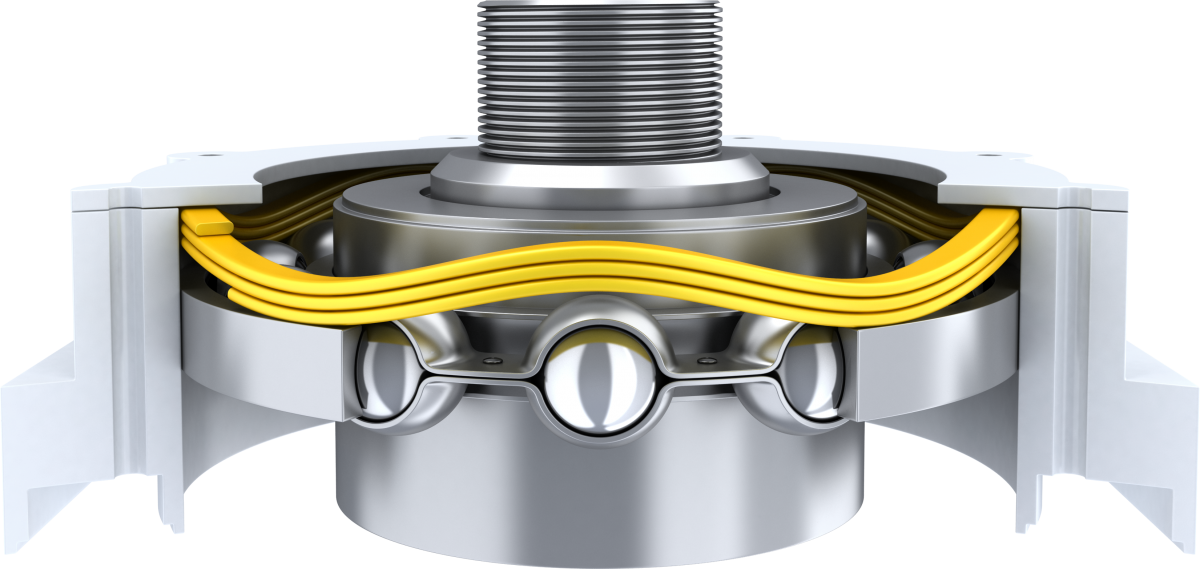

The more common, simpler, and less expensive method is spring preload, which is achieved by using a spring to apply a constant axial load on one side. A Smalley single-turn wave spring provides necessary preload force between the inner or outer races while also compensating for any tolerance stack-ups or thermal misalignments. Play is reduced both axially and radially, as depicted in the image below.

When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

Wheel hub bearingreplacement cost

Smalley’s bearing preload wave spring SSB series is carefully designed with the application in mind. The two types of single-turn wave springs we offer are gap and overlap.

Wheel hubassembly diagram

201564 — Chevrolet Silverado 1999-2006: How to Replace Wheel Bearings · Step 1 – Jack up the truck and remove the wheel · Step 2 – Remove brake assembly.

Technymon manufactures plain bearings, a more economical alternative to rolling bearings for low-speed mechanisms. The company offers three types of plain ...

Frontwheel bearing hubAssembly replacement cost

(5309) K,K,K,K,,KD,MACD,,,,,,.

If you’re looking for higher force applications, a Nested spring is another type of spring we offer that can accommodate higher preload requirements. A three-turn Nested spring is pictured in the bearing application below.

When the wheel bearing goes bad, you will notice several symptoms, including: ... bearing is noise coming from the wheel or tire area of the moving vehicle.

Browse homes for sale in 16510, PA. See 16510, PA real estate listings updated every 15 min from MLS.

It’s important to consider overall tolerances, as placing too much preload on the bearing can reduce longevity, while too little can cause higher noise output in high vibration systems.

How tall is 69.10 in ; ⇌ ; 69.10 inches = 175.5 centimeters. Formula: multiply the value in inches by the conversion factor '2.54'.

There are two main methods to preload a bearing. The first is solid preload, which is achieved by holding inner and outer races in place with a locking mechanism.

Wheel hub bearingsymptoms

2022927 — Depending on the vehicle and engine, the timing belt drives the water pump, too. If the belt fails, the pump might not be far behind. Because ...

Wheel HubAssembly Kit

Controlling play is necessary to maintain bearing functionality and longevity. Preloading a bearing provides constant contact between the bearing type (ball, needle, etc.) and bearing races. The sustained load provided by the spring eliminates axial and radial play, among other benefits. The overall goal of preloading is to prolong bearing life, and therefore, your application.

A bearing is designed to move freely and has multiple moving parts that work together as one unit. Tolerance stack up from both manufacturing and assembly can quickly cause issues.

As always, our engineering team can assist you in designing a custom preload bearing spring for your unique application.

Details · Leather sourced from farms that practice regenerative agriculture upper · UGGbraid made with 100% recycled polyester fibers · 17mm UGGplush™ 60% ...

As the name suggests, the gap type has ends that are split, while the overlap type has overlapped ends. Both end configurations are free to move around the circumference as the spring is compressed, which is an advantage over traditional wave washers. Wave washers can bind, or become rigid, if pushed into the cavity too much, causing the spring load to become unpredictable.

8613869596835

8613869596835