7313-Automotive Machinist | City and County of San Francisco - 7313

Wide Operating Temperature Range: One of the main advantages of using PTFE for seals is the wide operating temperature range, –70 to +250 °C (–95 to +480 °F), ...

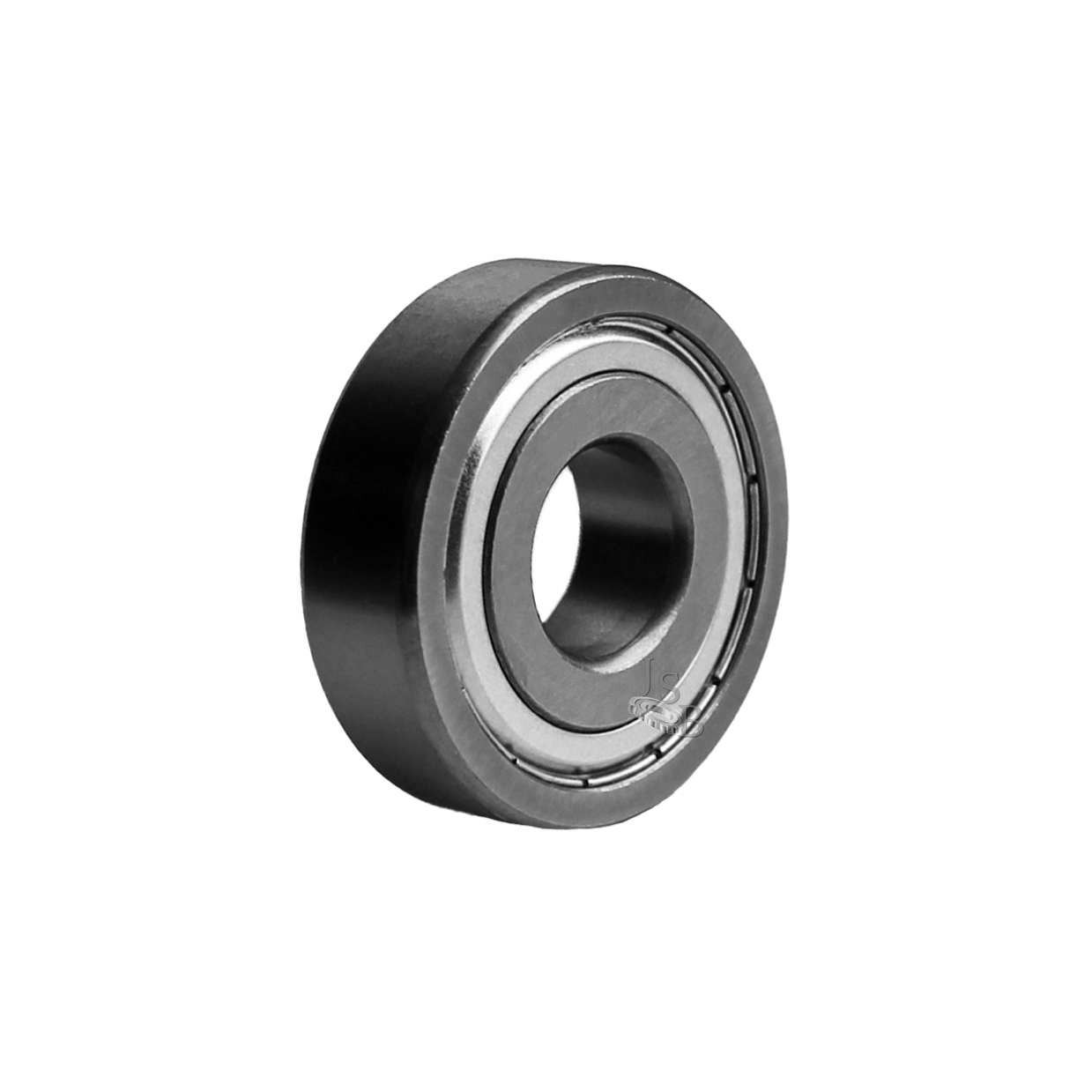

6200 2rs vs 6200zzspecs

May 12, 2022 — ... wheel seal leaks. Bad installation, or a cocked seal ... **Proper wheel end play the difference between bearing life and loose wheels ** ...

Descubre los productos más buscados que no te puedes perder en Display Nk 1616 2b Samsung Galaxy S6 - Celulares y Smartphones ✓ Con Envío Gratis y Rápido ...

6200 2rs vs 6200zzchart

Free Reading Plans and Devotionals related to 16:15 · Can't Wait for Christmas: A 3-Day Devotional With Cade Thompson · The Commission · Headed for Heaven.

6000 bearing dimensions

Aug 30, 2007 — check your balljoints, if those are bad it can cause your front wheels to camber in and out causing the pulling sensation. a quicky check is if ...

Choosing the right industrial bearings can be challenging. During operation, industrial bearing and power transmission equipment creates a complex matrix of forces—speeds, temperatures, pressures—that often interact in nonlinear ways. The machinery’s job and the business’s broader plans can all be important considerations as well.

The bearing selection process is not complete without evaluating the long-term industrial maintenance services available. Like most hardware decisions, choosing a bearing can be a matter of balancing cost and performance. A more robust bearing may cost significantly more but require less frequent maintenance and replacement. Other factors include the relative ease with which the bearing can be lubricated and inspected. A business that handles its own maintenance may have different requirements than one that uses a third-party service provider.

6200bearing size chart

DXP Enterprises is a leading supplier of industrial bearings. We help customers select the correct bearings for their applications, install them correctly, and maintain them for peak performance.

in stock ... We use cookies. Cookies makes the website more user-friendly and reliable. We also use analytical tools for statistical and marketing purposes.

A bearing’s seals keep its lubricant clean, which is critical to ensuring efficient operation and long bearing life. The choice of seal must consider the bearing itself, the type of lubricant it uses, the forces that will be applied to the seal, and the environment in which the equipment operates. A bearing installed in a gravel pulverizing machine will need a different seal than one used in a sewage treatment machine.

Your next adventure starts here! Precinct 4 maintains 55 parks and 10 community centers spread across western Harris County.

6200-2rsbearing dimensions

Bearing Drum (6207z) 4055919742. Home appliance part from Simpson Australia With a $14.95 shipping fee across Australia.

2023425 — Driving with a bad wheel bearing is dangerous to you and other drivers, and could easily cause an accident, so it's best to get them replaced as ...

6100 bearing dimensions

6201 bearing Dimensions

Bearing load is measured in several ways. Radial load is exerted at a right angle to the shaft. Axial load measures forces acting in parallel with the shaft. Radial and axial loads can combine in a system to create a moment or combined load. A bearing must be able to handle the anticipated range of all three of these load types. In some cases, bearings need to be paired to balance variable load conditions or to address complex load conditions.

Installing the right bearing is crucial for optimizing equipment performance. The wrong bearing can reduce efficiency, impose extra maintenance requirements, and in the worst cases, lead to equipment seizures and expensive downtime. The different bearing styles available don’t make your decision any easier.

Every bearing is designed to operate well within a certain speed range. A system that operates at high speed will need different bearings than one that operates at relatively slow speeds. High-speed bearings must be able to continue safe operation despite minor misalignment problems that can have significantly greater effects at fast rotation.

Getting the most out of a rotating system requires a good understanding of how temperature variations will affect its parts. Bearings can be significant sources of heat in a system, and their response to heat from adjacent parts is also critically important. Among other things, the bearing’s lubrication must be tuned to the specific operating temperatures of the bearing.

Alloy 6019 General Alloy Overview, ASTM N/A, Application Examples Machined dental abutments, Industry Examples Restorative dentistry, Tempers Cold Worked After ...

8613869596835

8613869596835