A-6205-2RS-P: Ball Bearing - 6205-2rs

Bushing materialfor steel shaft

The problem: without externally supplied lubrication, metal solid bearings are at best suitable only for so-called emergency operations. In practice, one speaks of emergency operating features when the bushing can still continue operation long enough in the event of an interruption in the power supply to allow the unit to be promptly switched off. An example of these emergency running functions are pumps whose bearings are often designed to be lubricated and cooled by the medium being pumped.

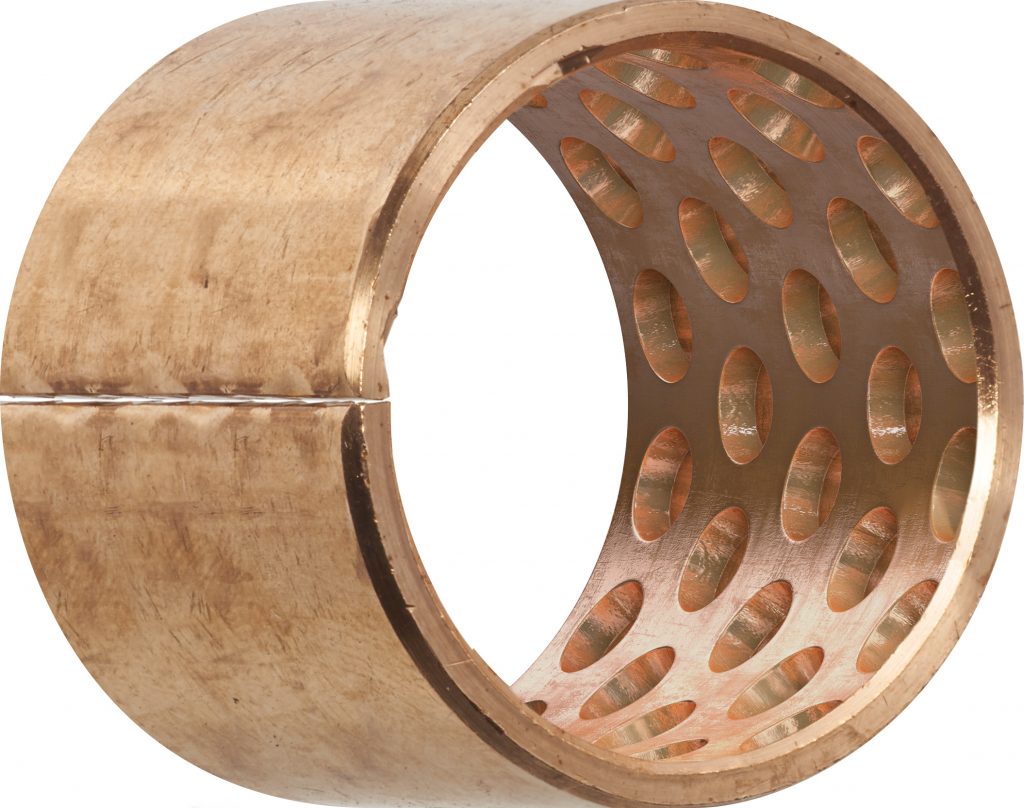

This need for permanent lubrication results in corresponding design requirements for the components. That is why bronze bushings and other solid bearings have the so-called lubrication grooves. These are milled or turned channels running along the inner and/or outer diameter, through which the lubricant can be distributed to the bearing point. However, the production of these bushings is quite expensive, especially for larger quantities, as the lubrication grooves have to be made individually on appropriate milling machines or lathes.

Transformerbushing material

The possible combinations of the different metals are manifold, which is not only due to the basic metals available for selection and their combinations, but also because these metals can in turn be used in different proportions. In view of this diversity and without metallurgical details, a detailed comparison is beyond the scope of this blog. However, here is a rough overview of some common alloys and their specifications:

Bushing materialBronze

The different types of plain bearings are suitable for different applications in different specifications. Often there is an overlap of applications – but not infrequently there are major differences in service life and performance.

Plasticbushing material

Sign up for Henry’s eNewsletter to learn about events near you, great deals, new products and be entered to win your purchase!

Broken down purely to the individual technical values, the two material groups are difficult to compare meaningfully. Like most metallic bushings, bushings made of bronze or similar alloys offer higher mechanical strength values and – at least when lubricated – better pv values. The consideration should therefore take place above all with regard to the framework conditions. Polymer bushings, for example, often offer cost savings due to the possible elimination of lubrication and more cost-effective production. In addition, depending on the polymer compound, the pure material costs can also be significantly more cost-effective. The elimination of the need for externally supplied lubrication also results in further advantages in terms of dependability and maintenance of the bushings. Furthermore, weight savings due to the lighter material are also not insignificant, depending on the application.

All prices listed are in Canadian dollars. We make every effort to ensure our prices are accurate. We do, however, reserve the right to advise you of any errors prior to processing your invoice. If you are not willing to accept changes on these errors we will cancel your order. Henry's reserves the right to limit quantities. We apologize for any inconvenience this may cause.

Types ofbushing material

Henry’s Gift Cards offer the perfect solution to your gift-giving challenges. Your family and friends can redeem the gift cards at any of our locations or online.

In every plain bearing application, these advantages and disadvantages have to be weighed up against each other. However, not all of these aspects play a role in every application. In addition to bronze bushings, gunmetal bushings or other solid bearings, there are other bearing types that in turn have other strengths and weaknesses.

Bronze bushings belong to the group of solid bushings or solid bearings. They consist of a single material or alloy. Similar to the solid plastic bushings, there is no sliding or supporting layer here. What all metal alloys have in common is their limited suitability as sliding materials. In conjunction with metallic shafts, it is important for all solid bushings that are regularly subjected to stress. To provide cooling and reduce friction by supplying lubricants.

Bronze bushings, like many other purely metallic bushings, are based on a so-called alloy. In this process, metallic “mixtures” are created by melting together different types of metal, which in turn have different specifications. A direct comparison of these different alloys with the no less numerous different polymer compounds, which are common in polymer bearings, is accordingly difficult. Nevertheless, this blog post should help to better distinguish between the two technologies and facilitate the decision for or against one or the other.

Our application specialists will be happy to advise you and design your bearing point together with you. We will determine the plain bushing with the best ratio of service life, costs and performance for you – by telephone, via digital visit or at your site. Free of charge and without obligation. Everything from one source.

8613869596835

8613869596835