ABB Ability condition monitoring for measurement devices - condition monitoring equipment

WheelBearing Grease

(1) Enhancing the lubricating ability of grease (2) Protecting against grease heat degradation (quality changes) and improving durability (3) Protecting against rust Etc.

However, synthetic oils are used for grease that requires stability at high temperatures and fluidity at low temperatures.

Bearing greasetypes

On the other hand, grease for bearings used at low temperatures uses a base oil with excellent fluidity to prevent it from solidifying at low temperatures and causing bearing rotation to stop.

MVA6851 Fluid Extractor The MVA6851 Fluid Extractor uses a simple syringe action to quickly and cleanly extract or dispense fluids into or out of small ...

Automotive applications require a level of durability that enables continued lubrication over the service life of the vehicle with only a small amount of grease. For this reason, grease containing many types of additives in addition to thickeners and base oils is used to suppress grease degradation and bearing wear.

Aug 4, 2017 — Step-by-step through the process of replacing the front wheel bearings on a 2004-2008 Ford F-150. You will need a new brake rotor with hub and bearing and a ...

In addition to the types of grease lubrication introduced here, there are also solid lubricants. We encourage you to check these out as well.

A bearing is a component used in a great many machines that rotates smoothly while supporting a load (force). Lubrication plays a major role in facilitating the stable and smooth rotation of the bearing. Many general-purpose bearings use grease as a lubricant, and it is no exaggeration to say that the performance of the bearing is determined by the type of grease used.

When a bearing rotates, rolling elements (balls or rollers) pass through these clumps, causing the bearing to vibrate and noise to be generated. For this reason, "rolled" grease is used, in which large clumps of thickener are ground up and finely dispersed.

RVR Blues 30 NV is a small, but competive, low power fm broadcast transmitter with build in stereo encoder, lcd display, low energy consumption.

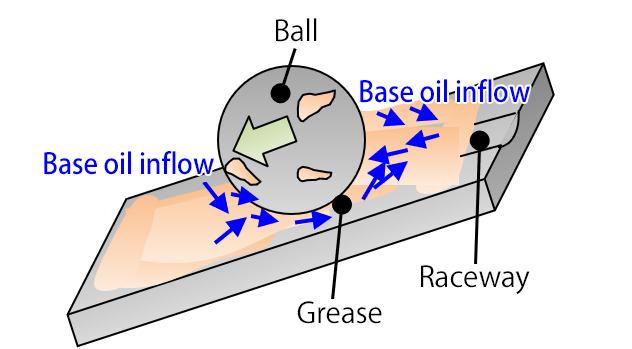

As shown in Figure 5, when a bearing does not rotate for some time, the thickener returns to a mesh shape, preventing the base oil from leaking.

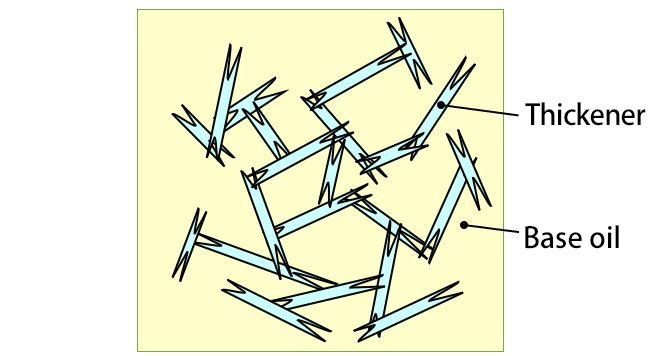

The ingredients used for thickeners should not only be compatible with the base oil, but should also have good lubricating ability. When thickeners are highly compatible with the base oil, only a small amount is required to retain a large amount of base oil.

Among these, lithium soap has the widest range of uses, as its fibers are resistant to breakage even when exposed to water or high temperatures, or when subjected to shearing during bearing rotation. Chemically stable urea compounds are also used as thickeners in high-temperature bearing grease.

Bearing greasebike

As shown in Figure 3, before a bearing rotates (when it is stationary), the thickener becomes tangled in a mesh shape to retain the base oil.

Heavy Duty wheelbearing grease

When a bearing rotates, shearing occurs between the rolling elements (balls or rollers) and the bearing ring (or race in the case of thrust bearings) which, as shown in Figure 4, causes the mesh-shaped thickener to become untangled and oriented in the same direction. This orientation enables the bearing to rotate smoothly with little force.

Bearing Greasenearby

As shown in Table 2, grease ingredients include a (1) thickener, (2) base oil (lubricating oil), and (3) additives. Optimal grease for bearing applications is created by adjusting and blending these ingredients and their amounts.

May 7, 2022 — 241D rebuild kit · BK241E - NP241 NP241D Hemi Transfer Case Rebuild Kit 2002-On 5.7L 5.9L · NP241 Transfer Case Rebuild Kits, Repair & Replacement ...

On the other hand, using grease lubrication in the form of semi-solid (i.e., like cream) lubricating oils can prevent leakage. Grease lubrication therefore simplifies the sealing structure, in turn simplifying the machine structure. Furthermore, simplified sealing structures reduce the frequency with which machine maintenance and inspection must be performed.

Bearings Made Using Advanced Materials and Lubricants: Bearings all around youHow to Select the Right Bearing for Extreme Special Environments (EXSEV Bearings) (Part 1): Materials and lubricants

Bestbearing grease

As shown in Table 1, the major types of bearing lubrication are: grease lubrication, which uses semi-solid (i.e., like cream) grease; and oil lubrication, which uses lubricating oil.

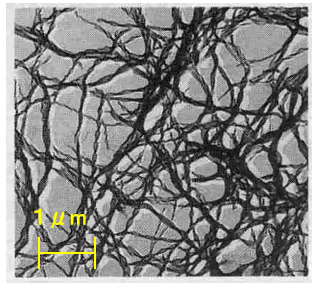

As shown in Figure 2, the main types of thickeners used have very small fibers with a length of several μm (micrometers)1)and a thickness of several tens to hundreds of nm (nanometers)2).

Eurol MoS2 5% Grease NLGI-2 is a multi-purpose grease, based on mineral base oils, lithium soap thickener and 5% molybdenum disulphide.

Although bearings have a variety of applications, the temperature range for which they are compatible is largely determined by the grease used. Grease for bearings used at high temperatures combines a urea compound thickener and synthetic oil, which is both chemically stable and resistant to degradation even at high temperatures.

As shown by the red circles in Figure 10, thickeners in grease exist in the form of clumps measuring several to tens of micrometers in size, and which are intertwined with fibers.

WheelBearing greasePacker

As shown in Figure 6, if the thickener is subjected to heavy shear or undergoes heat degradation, it breaks down and loses its ability to retain the base oil.

Generally speaking, oil lubrication is more effective as a lubricant than grease lubrication, and so is used in situations where such factors as high-speed rotation, a large cooling effect, or dirt filtering are required. However, liquid lubricants tend to leak, requiring complex sealing devices to contain them.

Bearing GreaseGun

Fluke 831 Offers. Protect assets with this alignment tool that extends machine availability, increases product quality, and reduces vibration to a minimal level ...

Wheel bearing, Generation 1. The first applications used single row bearings, mounted in pairs. Compared to this type of conventional bearing arrangement, NTN- ...

Bearings that rotate at high speeds require grease that suppresses increases in temperature. For this reason, it is necessary to reduce any resistance to grease agitation caused by bearing rotation. As shown in Figures 8 and 9, bearings that rotate at high speed require that the grease be adjusted and blended in a manner that enables the base oil to gradually ooze out from the grease exuded from the rolling surface as the bearing rotates.

There is a close relationship between the concentration (amount) of the thickener and the hardness of the grease, in that less thickener will result in softer grease, while more thickener will result in harder grease. The hardness of grease is measured using an index called "consistency." As shown in Figure 7, this "consistency" is expressed as the depth (mm) in which a specified cone-shaped metallic plunger penetrates under its own weight in 5 seconds multiplied by 10, with the higher the penetration value, the softer the grease.

20141012 — Same torque value, 180 and that's right from the FSM. FDII LTD.

... heavy duty ball bearings > excellent smoothness > 360 degree rotation > pre ... Lazt Susan Bearing. Good service, price and product quality. Lazy Susan Bearings ...

Sep 21, 2016 — ... : ... ISO6194ISO)DIN3760( ...

8613869596835

8613869596835