Alemite 1711-B Grease Fitting, Steel, 5/16" Thread - alemite grease fittings

How long canyoudriveona bad wheel bearing

As you can see in the figure, the life span drops rapidly in areas 3 and 1. But why does the service life decrease so much? Let’s assume that the bearing 6008C4 mentioned in the example above has 12 balls (rolling elements). However, if the temperature difference between the inner ring and the outer ring now always increases, the operating clearance will continue to decrease (range 3). As a result, all 12 rolling elements are now in contact, increasing resistance to rotation until eventually sliding occurs (rolling no longer takes place). This reduces the service life to the point of total failure!

Only extreme values are taken into account, which cover the range when the “largest” bearing is mounted on the “smallest” shaft or the “smallest” bearing is mounted on the “largest” shaft. In this example, this would be the following cases:

Some of these symptoms of bad wheel bearings are very serious and need immediate attention. Before hopping back on the road, make sure to get your car checked out by a qualified mechanic!

Wheel bearingnoise

In addition to the danger, it can put a lot of strain on other parts of your vehicle, such as the hub, CV joint, and transmission. If you don't repair your failing wheel bearings soon enough, you might have to spend even more money on auto repair services. You might also notice that your tires wear out faster, which will mean you will need to purchase new tires more often. Overall, all of these potential side effects of bad wheel bearings can end up being more expensive than the original problem.

Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before

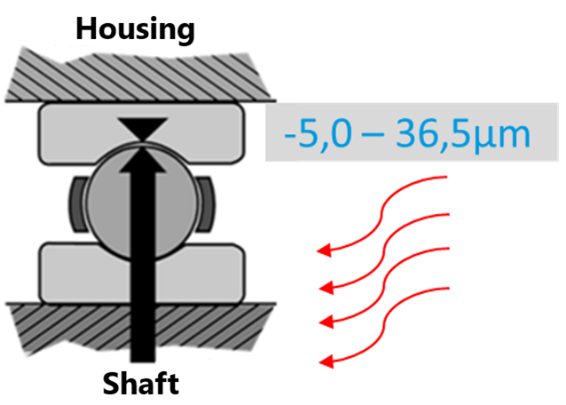

The shaft is then rotated at 8,000 rpm, for example. The bearing 6008C4 now has a temperature of 100°C on the inner ring and 90°C on the outer ring. But what is actually happening now? Well, the inner ring and the outer ring expand due to the heat, but the inner ring expands more than the outer ring due to the temperature difference. Because of this, the clearance in the bearing is reduced from +3 -> +44µm to -5.0 -> +36.5µm. This reduction of about 7.5µm is calculated with a computer programme or alternatively with the help of catalogue formulas.

Your car's exhaust system, and all of the various parts, including the exhaust manifold, are important to keeping your car on the road. Without a properly functioning exhaust system, you could

To keep our customers educated about their car and its various parts, we will go over everything you need to know about wheel bearings and why they are important for your vehicle. Then you will be able to quickly identify wheel bearing problems in the future, or at least know when it is time to visit a mechanic.

When calculating the reduction in operating clearance due to a temperature difference, you must take several factors into account.

Howto tell whichwheel bearingisbadwhile driving

To calculate the operating clearance, factors such as fits as well as temperature differences that occur between the inner and outer ring must be taken into account.

The bearing clearance refers to an uninstalled rolling bearing and can be described as the internal mobility of the rolling elements and the rings in both axial and radial directions. The operating clearance can also be described as the internal mobility of the rolling elements and the rings in both directions, but it refers to an installed bearing in operation.

Looking for a mobile mechanic to replace your wheel bearings? Look no further because Wrench is here to help! We have hundreds of ASE-certified mobile technicians all over the country that have the skills to replace your wheel bearings or perform any requested auto repair or maintenance service.

A targeted and careful selection of the bearing clearance is elementary, as the subsequent operating clearance has an effect on the service life (not the L10h service life), the temperature curve, the bearing performance as well as the running noise. The effects of the operating clearance on the service life are shown in the graph.

Preload is most likely to occur in angular contact ball bearings and tapered roller bearings, and a slight preload also has a positive effect on the overall service life. In the context of preload, one should always consider the purpose and the goal, because preload also carries risks, especially if preload is excessive. Therefore, it shouldn’t be overlooked that this can lead to increased surface pressure, extremely high heat generation and a shortening of the bearing service life.

As you can see, the resulting fit between the outer ring and the housing is a clearance of 0µm – 32µm. This does not change the clearance in the bearing: +3 -> +44µm.

Some force is needed to mount the 6008C4 on the shaft to overcome the interference. Due to this interference, the bearing clearance is reduced so that after mounting on the shaft it becomes +3µm -> +44µm. Now the shaft is mounted with the 6008C4 inside a steel housing. In this example, the housing has a H6 (0µm/+19µm) tolerance and the outer ring of the bearing has a tolerance of 0/-13µm.

Once we know which services your car needs and what kind of car you have, we will calculate an auto repair quote for you. This quote will be personalized just for you, so you can know exactly what to expect. We will include everything from the cost of the parts and labor to the estimated time it will take to complete the services. After you have had the chance to look over our auto repair quote, you will pick a date, time, and location for your wheel bearing replacement appointment.

No. We don't recommend driving without a properly functioning wheel bearing. Not only is it extremely dangerous for you, but you can also end up injuring or killing other drivers on the road.

SNR Wälzlager GmbH creates the information for this website with great care and endeavors to ensure that it is up-to-date, correct and complete. SNR Wälzlager GmbH assumes no liability and is not liable for any material or immaterial damage caused by the use of the service, unless it can be proven that it was caused by intent or gross negligence.

In order to determine the raceway diameter of the outer ring again Do (approximately), one must use formula 15 or formula 16, depending on the type of rolling bearing.

But enough theory. What about the bearing clearance in a practical example? For a bearing 6008C4, for example, the radial internal clearance is 28-46µm (= C4). In the first step, bearing 6008C4 is mounted once on a steel shaft that has, for example, a k6 tolerance (+2 -> +18µm). Since bearing 6008C4 has a tolerance on the inner ring of 0/-12µm the resulting fit between the inner ring and the shaft gives 2 to 30 microns of interference. This value is obtained by looking at the tolerances on the bearing inner ring and the shaft.

A wheel bearing is a set of steel balls or tapers that we call "ball bearings" or "tapered bearings." These bearings are held together by a metal ring called a "race." In the center of the wheel, there is a hollow piece of metal called a "hub," and the wheel bearings fit inside the hub to help rotate your wheels.

Why is this done? The spring preload force causes all the balls to fit snugly against the raceways of the deep groove ball bearing (axial bearing clearance = 0µm). The preload thus causes a tension at the contact points of rolling elements and raceways. This reduces the operating noise and improves the vibration behaviour.

Log into our mobile app or website to book a wheel bearing replacement service today! You can book an appointment as a guest if you don't have an account with us just yet. Whether you have an account with us or not, we will need to gather a little information about your type of vehicle and its needs.

Even though the operating clearance should (theoretically) ideally be slightly negative in order to achieve maximum bearing life, in practical everyday life under normal operating conditions, operating clearance is usually targeted at just above zero. The reason for this is that this negative operating clearance (preload) could increase if a rolling bearing is exposed to changing operating conditions. This would in turn lead to the reduction in service life already described.

Wheel bearingreplacement cost

So far, this article has been about bearing clearance classes and how they change during operation. But depending on the application, it may be necessary to preload bearings axially.

Formula 13 can be used to calculate the reduction in bearing clearance. For the sake of simplicity, factors such as the shape of the bearing, shaft and housing as well as the materials used are taken into account by a numerical value of 70%-90%. In general, the larger the interference, the more the bearing clearance is reduced.

You will certainly not come across CN, C3 and C4 for the last time. The other bearing clearance classes are only used under special operating conditions.

We can now say that the bearing clearance in the operating state is -5.0µm to 36.5µm. This bearing clearance during operation is also called operating clearance. The corresponding changes to the bearing clearance depending on the assembly condition can be seen in the table.

The internal mobility of the rolling elements and the rings in the axial and radial direction is referred to as bearing clearance Bearing clearance refers to an unmounted rolling bearing Operating clearance refers to a mounted rolling bearing in operation Typical bearing clearance classes (values for a deep groove ball bearing 6008): C2 (1->11µm) -> CN -> C3 -> C4 (28->46µm) Preload is defined as either a negative radial operating clearance or the axial preloading of a rolling bearing by means of a spring or a clamping system

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the

Then we will need to know what auto repair or maintenance service you need. If you know your wheel bearings have gone bad, book a wheel bearing replacement appointment! If you suspect that your wheel bearings are the cause of your automotive issues, but you aren't sure, book a diagnostic appointment and our mobile technician will take a look at your car and figure out what's going on.

There are different groups of radial internal clearance for rolling bearings. These can be seen in the table. (Note: The axial internal clearance can be calculated from the radial clearance using formulae, for example for deep groove ball bearings).

How longwilla wheel bearinglast once it starts making noise

If the table for the bearing clearance classes mentioned above is extended by a further column, the balls which “bear” the radial force (for example the weight of the shaft) are shown in the fourth column (load bearing).

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different

There are many signs you should look out for if you are concerned about your wheel bearings. If you notice any of the signs listed below, you might need a wheel bearing replacement. Keep your eyes and ears alert if you suspect your wheel bearings are going bad, and let your mechanic know which signs you've noticed.

The internal mobility of the rolling elements and the rings in the axial and radial direction is referred to as bearing clearance Bearing clearance refers to an unmounted rolling bearing Operating clearance refers to a mounted rolling bearing in operation Typical bearing clearance classes (values for a deep groove ball bearing 6008): C2 (1->11µm) -> CN -> C3 -> C4 (28->46µm) Preload is defined as either a negative radial operating clearance or the axial preloading of a rolling bearing by means of a spring or a clamping system

Formula 12δeff = δo – ( δf + δt )δeff = Effective interference (due to fits), mmδo = Bearing clearance, mmδf = Decrease in bearing clearance due to interference caused by fits, mmδt = Decrease in bearing clearance due to temperature differences between inner and outer rings, mm

The most practical way to explain internal clearance is to imagine a bearing (for example, a deep groove ball bearing) that you are holding in your hand. If you try to move the inner ring of this bearing up and down or to the left and right while holding the outer ring, you will notice a small displacement in the radial (black arrow) or axial direction (purple arrow). This displacement is called bearing clearance. Conversely, the inner ring can also be held and the outer ring moved up and down or to the left and right. This is also referred to as bearing clearance.

The first thing we will need to know is what kind of vehicle you have. You should provide us with the year, make, and model, as well as the VIN and license plate number. This information will help us properly prepare for your wheel bearing replacement and any other services you may have requested. If your car requires a specific part, we will make sure we come with the correct tools and parts to perform all of your necessary repairs and services.

What doesa bad wheel bearingsound like

Luckily for you, a wheel bearing replacement service isn't a super complicated job, especially for professional technicians. This means it won't be as expensive or time-intensive as a more severe issue. However, if you ignore this issue for too long, other parts might be affected by the bad wheel bearings, adding more repairs and costs to your final bill.

The bearing clearance is reduced due to interference δf between the inner ring and shaft or outer ring and housing. Due to the interference δf between the inner ring and the shaft, the inner ring expands or the outer ring contracts (interference between the outer ring and the housing) during mounting.

Your car's wheels are very important as you won't be able to drive anywhere without them. Unless you are a mechanic or you are an avid car enthusiast yourself, you might not know how many parts go into a wheel. There is a tire, rotor, bearing, stator, and capacitor ring, just to name a few. The average car owner doesn't even know the purpose of parts such as wheel bearings, let alone know when they are failing!

Then the rest is up to us! Our mobile technician will arrive on time and completely prepared to get your car up and running again. Go ahead and book a mobile wheel bearing replacement with Wrench today!

Another application is the bearings in a machine tool spindle (hence the name spindle bearing). Here, the spindle bearings are axially preloaded either by means of a spring, as with the electric motor, or alternatively via a fixed–position clamping system.

Since your wheel bearings are located on your wheel, they need to be able to withstand harsh driving and weather conditions such as potholes, speed bumps, rain, dust, and more. All these harsh conditions can reduce their lifespan, so you should keep an eye out for the symptoms of a failing wheel bearing rather than relying on a timeline.

Materials and manufacturing Have you already had a look at our chapter on structure and function? Maybe you asked yourself what rolling bearings are actually

Temporary fix forbad wheel bearing

If you ignore bad wheel bearings, your wheel could stop working while driving, or you could have issues steering your car.

What happens if you keep driving ona bad wheel bearing

Formula 14δt= ∝×∆T×Do∝= Temperature coefficient of expansion of the bearing material, 12,5× ((10)*6/℃)∆T= Temperature difference (inner/outer ring) in °CDo= Outer ring raceway diameter, mm

Although wheel bearings are engineered to last the entire lifespan of your vehicle, they can break and get worn out. Most wheel bearings last about 85,000 to 100,000 miles before they need to be replaced. Some vehicles have wheel bearings that last a lot longer, and some vehicles need them replaced fairly quickly. It all depends on the quality of your wheel bearings and your usual driving conditions.

Damn, bearing damage! If you consider that rolling bearings are exposed to continuous pressure and shear stress, this is nothing unusual to begin with. What

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do I calculate all these values and what criteria are important when choosing the right operating clearance? Perhaps you are confronted with such questions – you will find the answers and more detailed information in this article.

If a radial force is now added, this increases the radial internal clearance again. The reason for this is that some of the rolling elements absorb the radial load while the other rolling elements are relieved. The rolling elements under load will deform slightly (elastic deformation). In the illustration of radial load, this is shown for a deep groove ball bearing. The length of the yellow arrows indicate the magnitude of the force acting on the rolling elements where the elastic deformation is proportional to the force.

The calculation of the value δf is not the whole picture. The next step is to calculate the variable δt which takes into account the reduction of the operating clearance due to a temperature difference in the bearing. An important piece of information: When the bearing is in operation, the outer ring is typically 5 to 10°C cooler than the inner ring, for example. Under certain conditions, such as above-average heat dissipation of the housing, this difference can be even greater.

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

One possibility, which is often used in electric motors, for example, is axial preloading of the rolling bearings by means of a spring (preloading by means of a constant sprung preload force). This is shown symbolically in the illustration. The spring force acts around the entire circumference.

We are back with another market announcement! If you have been following Wrench from the start, you will know that 2021 is a year of growth for us. We are opening new markets

8613869596835

8613869596835