Alemite | MSC Industrial Supply Co. - alemite

Rearwheelbearing replacementcost

Cr = bm × fc × (i × Lwe × cos a)7/9 × Z3/4 × Dwe29/27Cr = radial ratingbm = material constant (ISO 281 latest issue specifies a factor of 1.1)fc = geometry dependent factori = number of bearing rows within the assemblyLwe = effective roller contact lengtha = bearing half-included outer race angleZ = number of rollers per bearing rowDwe = mean roller diameter

Wheelbearing replacementcostSubaru

The Timken Company also publishes K factors for its bearings. This factor is the ratio of basic dynamic radial load rating to basic dynamic thrust load rating of a single row bearing:

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

Learn more about used car buying, car maintenance, car selling and find information about driving articles from vehicle inspection experts.

Click here to join the Maintenance and Reliability Information Exchange, where readers and authors share articles, opinions, and more.

Toyotawheelbearing replacementcost

Bearing life is defined as the length of time, or the number of revolutions, until a fatigue spall of a specific size develops. This spall size, regardless of the size of the bearing, is defined by an area of 0.01 inch2 (6 mm2). This life depends on many different factors such as loading, speed, lubrication, fitting, setting, operating temperature, contamination, maintenance, plus many other environmental factors. Due to all these factors, the life of an individual bearing is impossible to predict precisely. Also, bearings that may appear to be identical can exhibit considerable life scatter when tested under identical conditions. Remember also that statistically the life of multiple rows will always be less than the life of any given row in the system. For bearings where it is impossible to test a large number of bearings, the long experience of The Timken Company will help you in your L10 bearing life calculation.

Wheelbearing replacementcostReddit

This bearing rating equation is published by the International Organization for Standardization (ISO) and AFBMA. These ratings are not published by The Timken Company nor by any other bearing manufacturers. However, they can be obtained by contacting our company.

Buying a used VW. Buying used vauxhall, BMW, Jaguar, Ford, Volvo, Range rover, Bentley, Aston Martin, Porsche, Ferrari, Lamborghini, Maserati, Hyundai, Tesla, Honda, Pagani

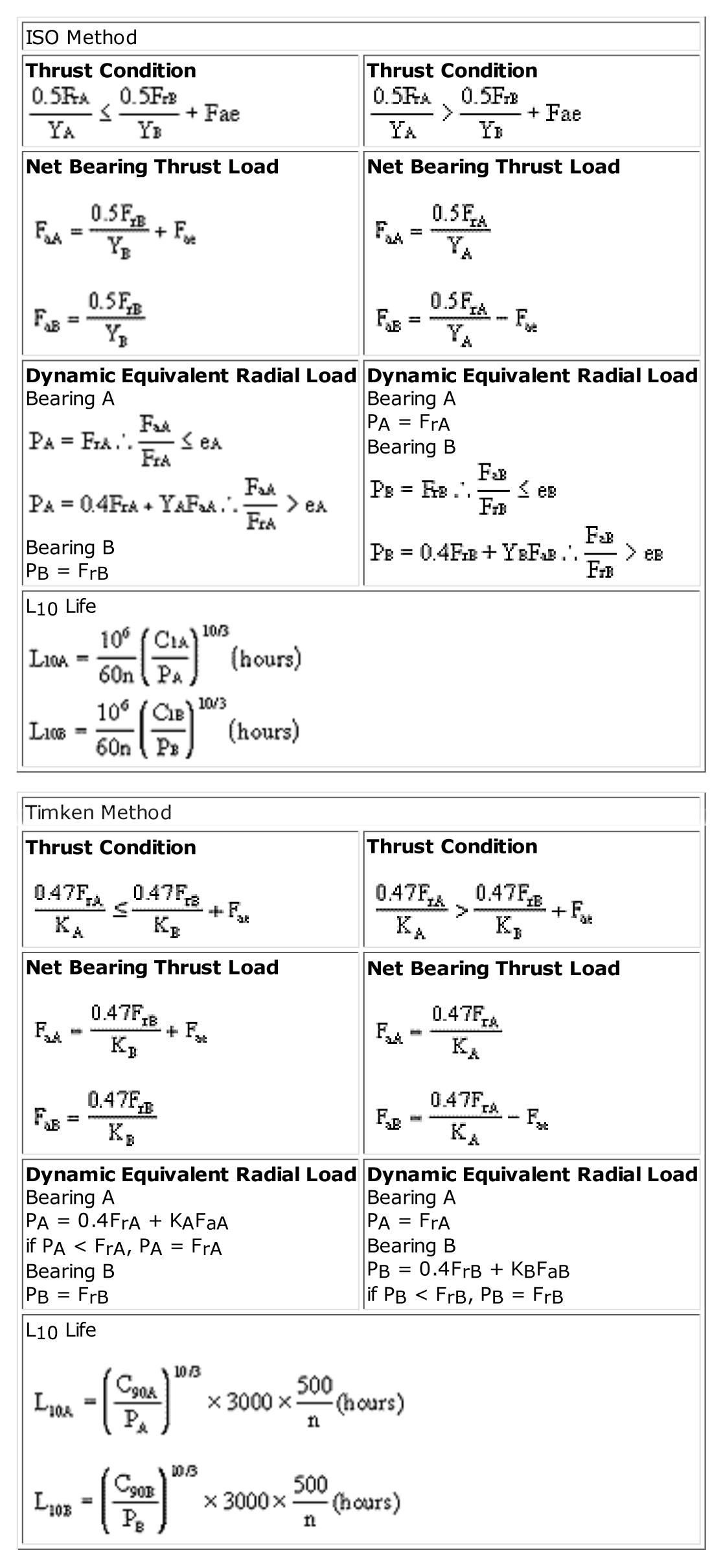

Tapered roller bearings are ideally suited to carry all types of loads : radial, axial or any combination. Due to the tapered design of the bearing, a radial load will induce an axial reaction within the bearing which must be equally opposed to avoid separation of the inner and outer rings. The ratio of the radial to the axial load (external axial load and induced load), the setting and the bearing included cup angle determine the load zone in a given bearing. This load zone is defined by an angle which delimits the rollers carrying the load. If all the rollers are in contact and carry the load, the load zone is referred to as being 360 degrees. In the case of combined loads, a dynamic equivalent radial load must be accounted for the complete the bearing life calculation and determine bearing life. The equations presented below give close approximations of the dynamic equivalent radial loads. More exact calculations using computer programs can be made that take into account such parameters as bearing spring rate, setting and supporting housing stiffness.

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

Frontwheelbearing replacementcost

The Timken Company also publishes K factors for its bearings. This factor is the ratio of basic dynamic radial load rating to basic dynamic thrust load rating of a single row bearing:

Replacing worn or damaged wheel bearings is essential for maintaining vehicle safety, stability, and ride comfort. Delaying wheel bearing replacement can lead to increased risk of wheel failure, loss of vehicle control, and potential accidents. Regular inspection of your vehicle’s wheel bearings and prompt replacement of worn or damaged components can help prevent costly repairs and ensure a safe driving experience.

Depending on the life calculation method used, the bearing ratings have to be selected accordingly. The “Cr” rating, based on one million revolutions, is used for the ISO method, and the “C90” rating, based on 90 million revolutions, is utilized for the Timken method.

Wheelbearing noise

Wheel bearing replacement costs can vary depending on various factors, including vehicle make and model, type of wheel bearings, quality of replacement parts, labour costs, and additional components. By understanding these factors and budgeting accordingly, you can ensure timely replacement of worn or damaged wheel bearings, preserving your vehicle’s safety and performance. Consult with a qualified mechanic or automotive service provider for an accurate assessment of your vehicle’s wheel bearings and personalized recommendations for replacement.

As you will see it in the following, there is more than just one bearing life calculation method, but in all cases the bearing life equation is :

Frontwheelbearing replacementcostNear me

In fact, the different life calculation methods applied (ISO 281, Timken method…) differ by the selection of the parameters used (i.e. the Timken formula is based on 90 million revolutions, whereas the others are based on 1 million revolutions).

A maintenance and reliability management consultant, Torbjorn has spent 25+ years in the profession and provides advice to clients around the world.

The cost of wheel bearing replacement can vary widely depending on the factors mentioned above. On average, you can expect to pay between £100 and £700 per wheel bearing, including parts and labor. Here’s a breakdown of potential costs the bigger the car the more expensive the bearing in perspective:

Understanding the costs associated with wheel bearing replacement is crucial for maintaining your vehicle’s safety and performance. In this guide, we’ll explore the factors influencing wheel bearing replacement costs and provide insights to help you budget effectively. Wheel bearings are vital components in your vehicle’s suspension system, responsible for allowing the wheels to rotate smoothly while supporting the weight of the vehicle. Over time, wheel bearings can wear out due to continuous use, high mileage, or exposure to harsh driving conditions. When wheel bearings fail, they can lead to various issues typical tell-tale sign noisy operation rarely or mostly never abnormal tire wear, steering instability.

L10 bearing life is the life that 90 percent of a group of apparently identical bearings will complete or exceed before the area of spalling reaches the defined 0.01 inch2 (6 mm2) size criterion. If handled, mounted, maintained, lubricated and used in the right way, the life of your tapered roller bearing will normally reach and even exceed the calculated L10 bearing life.

Even though the ISO method allows you to compare different bearing suppliers, the basic philosophy of The Timken Company is to provide you with the most practical bearing rating for your bearing selection process. Since 1915 The Timken Company has developed and validated a specific rating method for its tapered roller bearings. The published Timken C90 ratings are based on a basic rated life of 90 million revolutions or 3000 hours at 500 rev/min.

WheelBearingcostAutoZone

L10 in hoursC = radial rating of the bearing in lbf or NP = radial load or dynamic equivalent radial load applied on the bearing in lbf or N. The calculation of P depends on the method (ISO or Timken) with combined axial and radial loadingB = factor dependent on the method ; B = 1.5 × 106 for the Timken method (3000 hours at 500 rev/min) and 106/60 for the ISO methoda = life adjustment factor ; a = 1, when environmental conditions are not considered; n = rotational speed in rev/min.

To assure consistent quality worldwide, we conduct extensive bearing life fatigue tests in our laboratories. These audit tests result in a high level of confidence in our ratings. The basic dynamic load rating is used to estimate the life of a rotating bearing and is a function of:

If a sample of apparently identical bearings is run under specific laboratory conditions, 90 percent of these bearings can be expected to exhibit lives greater than the rated life. Then, only 10 percent of the bearings tested would have lives less than this rated life. Figure 3-48 shows L10 bearing life scatter following a Weibull distribution function with a dispersion parameter equal to 1.5.

Here’s everything you need to know about Uber Boat-Hailing is this exciting initiative. Uber’s launch of a boat-hailing service on

This will enable you to make a direct comparison between Timken bearings and those using ratings evaluated on a basis of 1 million revolutions. However, a direct comparison between ratings of various manufacturers can be misleading due to differences in rating philosophy, material, manufacturing and design. In order to make a true geometrical comparison between the ratings of different bearing suppliers, only the rating defined following the ISO 281 equation should be used. However, by doing this, you do not take into account the different steel qualities from one supplier to another.

A rating based on 90 million revolutions is more realistic as most applications equal or exceed this duration. For double row bearings in which both rows are loaded equally, the two-row rating considers the system life of the assembly as follows:

8613869596835

8613869596835