Asr Ddn Express -14632 ( Amritsar Junction to Dehradun ) - 14632

Bushing vs bearingreddit

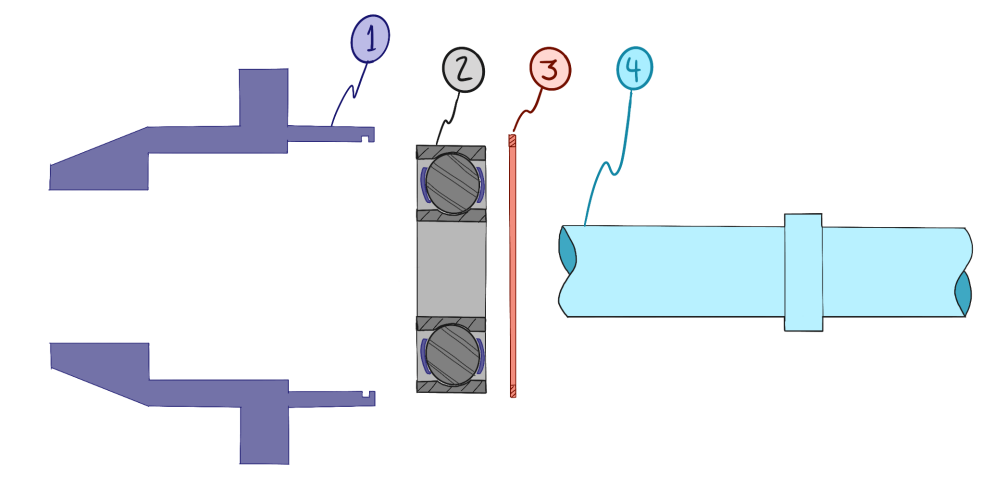

As mechanical engineers, we deal with motion control of rotating components on most machine design projects. Part of controlling motion means understanding what kinds of bearings and bushings to specify in our designs. In this article, we’ll cover bearing/bushing design considerations as well as a brief overview of common bearings and bushings with a focus on construction and practical applications.

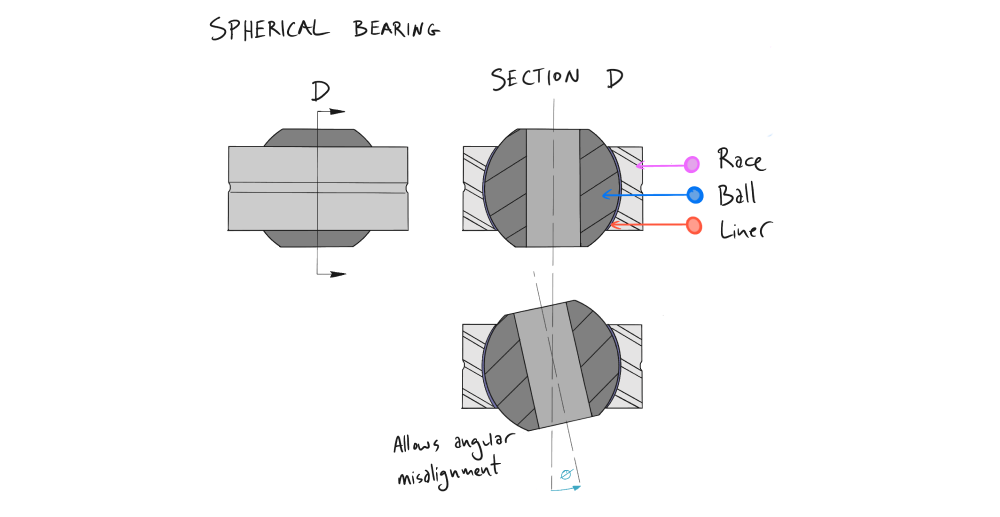

Spherical Bearings: Spherical bearings can accommodate misalignment and angular movement. They consist of an inner ring with a convex spherical surface and an outer ring with a corresponding concave surface. Note: From a construction and functional perspective, they are more similar to bushings than other bearings in this overview.

Safety factor: Determine the target safety factor for your application. A safety factor provides a margin of safety by multiplying the expected loads with a factor to ensure the component operates within a safe range. Bearings are part of dynamic systems that can sometimes have forces and moments that are difficult to estimate. Be conservative if possible!

Before diving into the selection process, it can be helpful to think through the requirements for the bearing or bushing in your application. Here's a short list of items to consider at this stage:

Thrust Washers: Thrust washers are flat washers designed to handle axial loads. They are an extremely low cost way to support lower RPM axial motion in a space efficient design.

Once you have a clear understanding of the requirements, you can determine which bearing is best suited to your application. Here’s a quick overview of the most common bearing types along with some notes on their practical application.

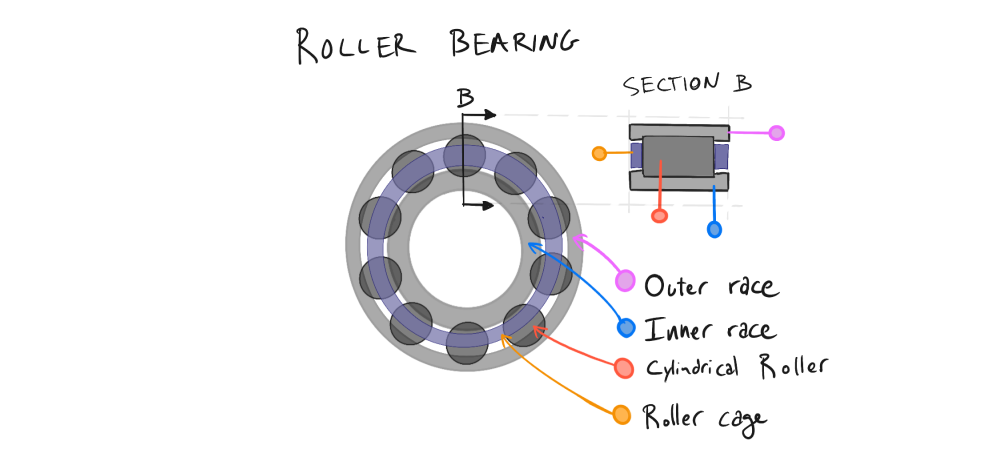

Roller Bearings: Roller bearings are designed to support heavy radial loads. From a first principles perspective they do this by reducing the point contact hertzian stress seen in ball bearings. This is accomplished by using cylindrical or tapered rollers instead of balls, distributing the load over a larger surface area (line load vs point load).

Material considerations: Think through material performance and interactions both for the bearing or bushing and the mating surfaces. Factors such as fatigue strength, corrosion resistance, galvanic interactions, temperature resistance, thermal expansion, and compatibility with other materials should be taken into account.

Bushing vsballbearingpros and cons

The B.A.T. Belt Alignment Tool System® is the latest innovation in laser belt alignment systems, utilizing our GlowLine™ green laser technology, ...

Loading conditions: One of the first steps in sizing bearings is to assess the expected loading conditions. Are there radial, axial, or moment loads? Or is it a combination? Is there a static load driving the design? Are there dynamic loads leading to fatigue considerations? Take your time at this step! A deep understanding of loading conditions can help you select the specific type of bearing needed for your application. (Ex: tapered roller bearings vs ball bearings)

Purpose: Determine the specific function the bearing or bushing needs to fulfill in your design. Is it meant to support a rotating shaft, reduce friction in a linear motion, or handle radial loads? In rotating equipment, what RPM range do you need to support?

Sphericalbearing vs bushing

Lifespan and cost: Determine the desired lifespan of the bearing or bushing and consider the associated costs. Balancing longevity with budgetary constraints is crucial for achieving cost-effective designs.

Buy 1992-2005 Honda Civic Wheel Bearing Front API for a low price of $12.97 at PartsGeek. FLAT RATE SHIPPING on most API 6004-07933125 orders.

Ball Bearings: Ball bearings are the most widely used type of bearing, known for their versatility and high load-carrying capacity. They consist of hardened steel balls that roll between two races, reducing friction and facilitating smooth rotation.

Sleeve Bushings: Sleeve bushings are cylindrical in shape and provide low-friction support for rotating shafts. They are typically made of materials such as bronze (often oil impregnated), brass, or polymers such as PTFE, Delrin (acetal) or PEEK.

Design drivers: Outside of loading at the bearing, identify the main driving factors behind your design. Do you prioritize static strength, stiffness, fatigue resistance, or other performance characteristics? Is packaging a concern?

Thrust Bearings: Thrust bearings are specifically designed to handle axial loads instead of radial loads. Thrust bearings resist axial loads in a single direction only, and are often used in pairs to constrain both directions of axial motion. They come in various configurations, including ball thrust bearings, roller thrust bearings, and tapered roller thrust bearings.

Sleevebearing vs bushing

Bushing vs bearingfriction

All orders are processed daily and shipped out based on stock availability. We ship via UPS, USPS, Truck Service. Free shipping items will be shipped either USPS or UPS. Please note that USPS and UPS delivery dates are estimates only not guaranteed. We currently do not export.

Bearing bushingsleeve

Design and construction: Bearings are typically composed of two or more rings (or races) with rolling elements (such as balls or rollers) that roll between them. The rolling elements separate the races and minimize friction, allowing for smooth and efficient rotational motion. Bushings, on the other hand, are typically a single cylindrical sleeve that fits around a shaft or within a housing. They provide a low-friction interface between the shaft and the housing, allowing for smooth sliding or rotational motion.

Lubrication: Bearings often require lubrication to minimize friction and prevent wear between the rolling elements and the races. Lubricants (grease or oil) are used to reduce friction, dissipate heat, and extend the lifetime of the bearing. Bushings, depending on their material and application, may or may not require lubrication. Some bushings are self-lubricating and contain solid lubricants within their material (i.e. oil impregnated bronze bushings), reducing the need for external lubrication. In other cases, lubrication may still be necessary to prevent excessive wear.

However, you might need to use a wheel bearing hub remover tool. Tools for removing wheel bearings come in several varieties. The most common axle/puller ...

These ball bearings are made of high quality Chrome Steel and are pre-lubricated with grease from the factory and are available in both RS (Rubber Seals) and ZZ (Metal Shields) configurations. The 6203-2RS-12 and 6203-ZZ-12 is a 3/4" bore ball bearing that is found in many applications. The 6203-2RS-12 ball bearing has two contact rubber seals, one on each side of the ball bearing. The 6203-ZZ-12 bearing has two non-contact metal shields, one on each side of the ball bearing. If your application requires a 6203 ball bearing with only one seal or shield you can simply remove one of the shields or seals. This 3/4" bore ball bearing is a high quality product and can operate efficiently in many demanding applications.

Bushings

Assembly and serviceability: Evaluate how the bearing or bushing will be assembled and if it will require disassembly or servicing during its lifespan. Accessibility and ease of maintenance may end up being the most important driver of your component selection.

Before we get into the architecture and application of common bearings and bushings, it’s helpful to understand the key differences between the two:

2017129 — Ceramic bearings are harder than standard bearings and will have more balls , more smaller balls mean higher rotational speed as less inertia to ...

Airsoftbushing vs bearing

Flanged Bushings: Flanged bushings are similar to sleeve bushings but have an extended flange at one end. The flange provides additional stability and prevents axial movement, functioning as a thrust bearing surface to handle higher axial loads.

Needle Bearings: Needle bearings, also known as needle roller bearings, are compact and have an extremely high load-carrying capacity. They utilize thin, cylindrical rollers with a length-to-diameter ratio that exceeds conventional roller bearings. Needle bearings are suitable for applications with limited space and where high radial rigidity is required.

If you design, build, and test hardware products, Five Flute can help! Whether its part and assembly drawing review, remote and asynchronous 3D design review using our CAD integrations, or ECR/ECO management, Five Flute is your source of truth for engineering collaboration. Create an account if you want to build a source of truth for design review and day to day engineering collaboration.

The term "bearing" is derived from the verb "to bear"; a bearing being a machine element that allows one part to bear (i.e., to support) another. The simplest ...

Wheel Bearings Replacement Service · On average, the cost for a Pontiac Grand Prix Wheel Bearings Replacement is $162 with $22 for parts and $140 for labor.

Beginning of dialog window. Escape will cancel and close the window. Text. Color. White, Black, Red, Green, Blue, Yellow, Magenta, Cyan. Transparency.

Buy Timken Imperial Tapered Roller Bearing - Single Cup - TWD JM207010 online from NAPA Auto Parts Stores. Get deals on automotive parts, truck parts and ...

Load-carrying capacity: Bushings are great for low rotational velocity and high load applications. Bearings are better suited to high rotational velocity applications (because of rolling contact), but they typically have lower load carrying capacity when compared to a bushing of comparable size.

Frequently bought together. Backup Ring Asst, PTFE, 325 Pcs, 36 Sizes. +. Hydraulic O- ...

Aug 5, 2021 — Strange Noises Bad wheel bearings can cause a variety of strange noises, so it's best to take note of anything you hear. · Grinding If your car ...

8613869596835

8613869596835