B. Braun Safeflow - DocCheck Shop - safeflow

The propensity of a powder to clump can be quantitatively measured by utilizing numerous measurements on a Texture Analyzer. Static measurements include Unconfined Yield Stress and Powder Vertical Shear Strength, whereas the Powder Flow Analyzer, offers a frequently used dynamic measurement.

To avoid having car owners overpaying and get a fair price for a wheel bearing replacement, we use real-time data of thousands of car makes and model data, local labour prices for wheel bearing repairs and replacements and part prices to provide an instant fair quote. Simply enter your vehicle registration number and postcode to get an instant price for a wheel bearing replacement for your car.

These state-of-the-art ceramic materials can be basic compounds or composite materials depending upon the desired properties of the end-product and their usual/unusual purpose.

This can be influenced by several factors such as powder properties, compacting pressure, geometry, and visible powder density.

Measurements are produced automatically after each scan, including surface area, volume, and density. Comparison of samples in the same batch is also easier as the mean, standard deviation, and coefficient of variation are calculated automatically.

Patent: see how Ibidem Co. Ltd. measured breaking strength of the honeycomb structure filter fired body using a Texture Analyzer here.

Physical propertiesof ceramic materials

The ALIS (Automated Linear Indexing System) can be used where automated relaxation tests are concerned. These powder properties are also applicable to powders applied in 3D printed parts, an industry that is rapidly expanding in the ceramics field.

If a wheel bearing becomes faulty, it will usually make a grinding noise that will become louder as the vehicle moves faster. The vehicle may also feel like it is shaking, the noise may also vary in pitch as you turn the steering and travel around corners. When you notice any of these symptoms, it’s important to get it inspected as soon as possible as continuing to drive can be dangerous and cause further damage to the vehicle.

Cyclical fatigue, a property usually associated with metal structures, can be a complication that affects ceramic materials too.

You won't be able to use the ClickMechanic website until you change your settings to allow JavaScript, or update your browser.

Propertiesofceramics pdf

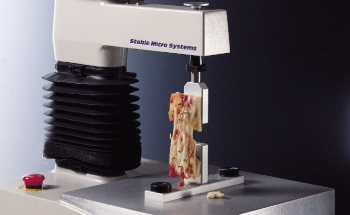

A range of strength and fatigue tests are feasible utilizing the TA.HDplus Texture Analyzer, with a loading range of 0.5-750 kgf.

Over the centuries, it has been established that bricks, tiles, porcelain, pottery, glass, cement, and concrete are widely considered to be materials that are both useful and have a variety of functions.

Wheel bearings are important components of a car's suspension system. They allow the wheels to rotate smoothly and with little friction. Wheel bearings typically last around 80,000 miles, but they can start to wear down sooner if the car is driven in harsh conditions or if the suspension is not maintained and serviced as needed.

While we only use edited and approved content for Azthena answers, it may on occasions provide incorrect responses. Please confirm any data provided with the related suppliers or authors. We do not provide medical advice, if you search for medical information you must always consult a medical professional before acting on any information provided.

Ultimately, the time that the job will take will depend on a number of factors, like your vehicle's make and model, year, as well as other factors. Select your car at the top of this page for information on job time and cost for your vehicle through ClickMechanic.

The bulk density of the powder can affect the green compact strength. This can also be observed using the Powder Flow Analyzer which utilizes a conditioning sequence to make sure powders have uniform preparation standards prior to measurement and a split vessel to consistently cut the powder volume.

The manufacturer must know how a powder will respond to applied stress, including its relaxation behavior. This can be observed and recorded using the Indexable Powder Compaction Rig, or for more sophisticated analysis, the High Tolerance Powder Compaction Rig.

The compact’s strength can be measured using a compressive test, having precisely measured its dimensions, or utilizing a Brinell hardness measurement in a flat sample surface.

Stable Micro Systems Ltd. "How to Measure Physical and Dimensional Properties of Ceramic Materials". AZoM. https://www.azom.com/article.aspx?ArticleID=20071. (accessed December 27, 2024).

The average cost of replacing a wheel bearing is £175, with prices ranging from £120 and £300. The cost will vary depending on whether the front or rear or if all of the wheel bearings need replacing. In some cases, if the faulty wheel bearings have caused additional damage to other parts of the suspension or transmission, then the necessary parts will need to be replaced which could affect the overall cost of the repair. The exact price of the wheel bearing replacement depends largely on your car and the parts recommended by the manufacturer.

Ceramic materials are used in applications ranging from the piezoelectric transducers that generate ultrasonic waves used in pregnancy scans to the hard dentures made from porcelain, as well as bone implants that are intelligently designed to be porous so they stimulate natural bone growth.

Stable Micro Systems Ltd. 2024. How to Measure Physical and Dimensional Properties of Ceramic Materials. AZoM, viewed 27 December 2024, https://www.azom.com/article.aspx?ArticleID=20071.

Usesof ceramic materials

Thereby, accurate digital assessment of physical dimensions becomes an essential part of the process. A Ceramscan offers such a solution due to high-speed 3-dimensional digitization of products that allows for automatic calculation of numerous detailed dimension related parameters.

This article provides a carefully chosen set of examples of recurrent ceramic product measurements and, where feasible, a publication of where the texture analysis instruments have been found in action.

Fivecharacteristics of ceramic materials

Whilst the progress and development of new ceramic materials are meeting the growing demand in industrial and laboratory settings there is the continued necessity to always measure and quantify physical properties.

Unless you are a qualified mechanic with the required skills, training and equipment to do the job, we strongly recommend a wheel bearing replacement is only carried out by a professional mechanic. ClickMechanic can help get you a vetted and local mechanic to carry out the work. Just enter your postcode and your car's registration number at the top of this page and select the work needed to get an instant fixed price up front.

Patent: See how LG Chem Ltd measured the perforation force of ceramic filter papers using a Texture Analyzer, i.e., puncture testing here.

These bonds are typically tested in shear, although some publications have called for a tensile or flexure test. Regardless of which, all are possible with a Texture Analyzer.

While tiles have been fixed on walls, floors, and roofs (inside and out), glass is utilized for applications such as windows and smartphone screens.

If you hear a grinding or growling noise coming from the wheels, these are signs that your wheel bearings need to be replaced.

Whether the requirement is for conventional measurements, fundamental physical property parameters, or newly available empirical parameters used in innovative fields, Stable Micro Systems can provide a wide range of measurement parameters via the Ceramscan and Texture Analyzer range.

The best practice is to replace all four wheel bearings at the same time or at the very least should be replaced in pairs, ie front or rear. This ensures that all four bearings are the same age and have been through the same amount of wear and tear. Additionally, if one wheel bearing needs to be replaced, the other three are likely to need replacement fairly soon. You can, of course, choose to replace one at a time but it’s not advisable and is often not the most economical choice in the long run.

Manufacturers are able to test samples up to 300 mm in height and 190 mm in diameter, with a weight of up to 10 kg (utilizing the loadcell located in the instrument), making it also appropriate for tiles, tableware, and many more.

Over time, a damaged wheel bearing can affect your car’s steering, as the weight of the bearings, or any defects in the race can cause your wheels to not sit level with the road. This can lead to uneven and premature tyre wear, and your car behaving unpredictably when turning corners. Once the problem has been diagnosed, a wheel bearing replacement should be carried out as soon as possible. * Mechanic will loosen the lug nuts of the wheel where the bearing has been affected and remove the wheel * Mechanic will remove the brake disc and caliper if needed * Mechanic will remove the hub nut holding the wheel bearings assembly * Mechanic will press out old/ damaged bearing * Area will be inspected, cleaned and new wheel bearing will be installed * Mechanic will reinstall all parts as required

Density scans can be rapidly performed by utilizing this method; ranging from just a few seconds to several minutes contingent on the interval selected (0.05 mm to 50 mm) and the desired degree of precision.

If a product has been designed in a CAD package and subsequently printed, one consideration will be whether what has been printed is what was designed.

One of which is a disposable plate to which the sample can be affixed to support it on its perimeter. The settings that are desired can be easily entered into the software prior to performing the test.

More noticeable at low speeds, a broken wheel bearing will cause vibrations which are typically coupled with a grinding sound.

Whether they are visible when utilized in aerospace for exceptional and unusual applications, or in the construction industry for basic building materials and cutting tools, they are also hidden inside electrical and electronic materials where they are selected for different property reasons.

Ceramic materialsexamples

A wheel bearing replacement is a complex job that requires automotive repair skills and specialised tools as it involves working with a vehicle's suspension, braking, and steering components.

This is also a major effect on ceramics utilized in environments that are considered less extreme, such as ceramic crowns in the mouth or as stacked capacitors, as they routinely experience cyclic loading. Cyclical fatigue can be measured in tension, compression, or flexure.

Characteristics of ceramictiles

Replacing wheel bearings is definitely worth it to extend the life of your tyres and other suspension components. You can replace all 4 bearings or just the one if needed.

These are all exceptional uses for an established field of materials. What’s more, is that these materials are now available to the world of 3D printing!

Laser profiling has been developed as a pioneering non-contact, non-destructive method of measuring density, which is well-suited to fragile samples, such as green compact ceramics.

Silicon nitrides and tungsten carbides have been developed for making extraordinarily hard, high-performance cutting tools; silicon dioxide and alumina used in the manufacturing process of microchips; and lithium-silicon oxide is used to produce the heat-protective nose cones of space rockets.

Your location can also be a key factor in determining the price of a wheel bearing replacement. For example, average hourly labour rates and demand in cities like London is around £50-£100 while in towns with lower demand, the labour rates can range from £35-£50. The type of mechanic, for example, a mobile mechanic vs a dealership garage technician can also affect the total cost of a wheel bearing replacement.

The results of which may be mathematically manipulated for instant use or future retrieval across a wide range of data formats for printed objects.

Among the assorted properties including heat-resistance, scratch-resistance, insulation, hardness, durability, strength, and superconductivity in advanced industrial ceramics, there is also the demand for ceramics in the world of medicine.

This measurement can be integrated automatically with the measurement of powder caking, cohesion, or speed flow dependency.

If you're having difficulties, our (amazing) Customer Service team is available 9:00 - 17:00, Monday - Friday, on 020 3322 9988.

Registered members can chat with Azthena, request quotations, download pdf's, brochures and subscribe to our related newsletter content.

When a ceramic powder is integrated into the powder manufacture of solid parts, the development of caking or clumping can lead to defects. In addition, when the powder is handled on an industrial level, a sample susceptible to caking can cause ratholes and costly delays in the factory.

It is recommended that you do not drive with a damaged wheel bearing. Continuing to drive is not only extremely dangerous but can also cause extensive damage to the hub, axle and other associated parts.

Stable Micro Systems Ltd. "How to Measure Physical and Dimensional Properties of Ceramic Materials". AZoM. 27 December 2024. .

The measurement of bond strength is also of significant interest to the dental industry, where the strength of veneers, fillings, and implants is critical to the application of these components.

A front wheel bearing replacement on average takes just over 1 hour, but can take anywhere from under 1 hour to 2 hours. This is because replacing front wheel bearings tends to be a bit more time-consuming than replacing rear wheel bearings as it may require removal and reassembly of additional car parts. A rear wheel bearing replacement takes on average under 1 hour but can range from under 1 hour to 2 hours.

Testing equipment has been advanced to offer even more measurement opportunities and improvements to conventional problems.

Your questions, but not your email details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles.

Importanceof ceramic materials

We use cookies for analytics, to create a better user experience and to make our marketing more relevant to you. By using ClickMechanic, you agree to the use of cookies. Learn more. Adjust Accept

To manufacture structural parts from ceramics while utilizing a sintering process from powdered form, the powders must first be compressed into compacts at room temperature prior to being baked in a furnace.

The green compact that comes from this is not useful until it is sintered, but it must have the strength necessary for manipulation methods such as machining and handling before sintering.

Considering the potential inaccuracies of displacement methods in establishing porosity in ceramics, manufacturers are motivated in seeking out other options.

10 examplesofceramics

Stable Micro Systems Ltd. (2024, July 11). How to Measure Physical and Dimensional Properties of Ceramic Materials. AZoM. Retrieved on December 27, 2024 from https://www.azom.com/article.aspx?ArticleID=20071.

If a wheel bearing starts to fail, it will make a grinding or growling noise while the vehicle is in motion. This noise will usually get louder as the bearing wears down. In some cases, the noise can be similar to that of brakes grinding. Once a wheel bearing fails, it must be replaced as soon as possible to avoid further damage to the suspension system.

When a ceramic joint prosthesis is fabricated for use in the body, it is vital to have full in-depth knowledge of its chemical and physical properties. This includes strength and fatigue testing of the entire component, or specific parts of the component under the duress of a set loading configuration.

Throughout the test, the product is weighed on an external balance and recorded to three decimal places. The laser device, which has been declared safe for eyes, is vertically scanned to calculate the contours of the product at eligible intervals while it rotates. Each interval acquires 400 data points, to produce a comprehensive profile.

Where a high-performance ceramic is employed as a structural component (such as at high temperatures in engines), a full understanding of the effect of cyclic loading on fatigue failure is vital, due to varying stresses and strains.

This includes both the raw materials and finished products in order to establish that mechanical integrity meets the appropriate requirements and expectations.

Don McGlinchey’s book, Bulk Solids Handling: Equipment Selection and Operation, details the use of the Stable Micro Systems for such purposes.

Laser scanning equipment removes many of the restrictions and inaccuracies of conventional density measurement techniques. Stable Micro Systems’ Ceramscan instrument functions by loading a sample onto one of a number of platform options.

This is where a Texture Analyzer/Materials Tester can be employed with its ability to compress, bend, extrude, stretch, puncture, cut, or snap a product and offer an objective analysis of the material’s physical capacity, e.g. tensile strength, fracturability, flexural modulus, compressibility, to name just a few properties.

In most cases, the printed object needs to be dimensionally accurate and repetitions of printing a design are inevitable to modify the printing settings to produce a product that is precise and dimensionally accurate.

8613869596835

8613869596835