Ball Point Set Screws for NTN Ball Bearing Mounted Units - ball point bearing

It's generally recommended to have them inspected regularly, especially during routine maintenance checks. Additionally, consider the following factors that may accelerate wear and require earlier replacement, such as driving conditions and improper installation or maintenance.

Heavy dutyhydraulic cylinder seals

A damaged wheel bearing can also affect the wheel hub assembly, so it's important to have the entire system inspected and replaced if needed. This assembly connects your wheel and axle, providing structural support and allowing it to rotate.

At Goodhood mobile auto repair services, our experienced technicians can inspect your wheel bearings and replace them if needed. We use only high-quality parts and offer the best customer service available.

The repair process typically involves removing the wheel from the car, taking out the old bearing, cleaning all components, and installing new bearings. Following this process requires specialized tools and experience; therefore, it's best to leave it up to experienced professionals rather than attempting a DIY fix.

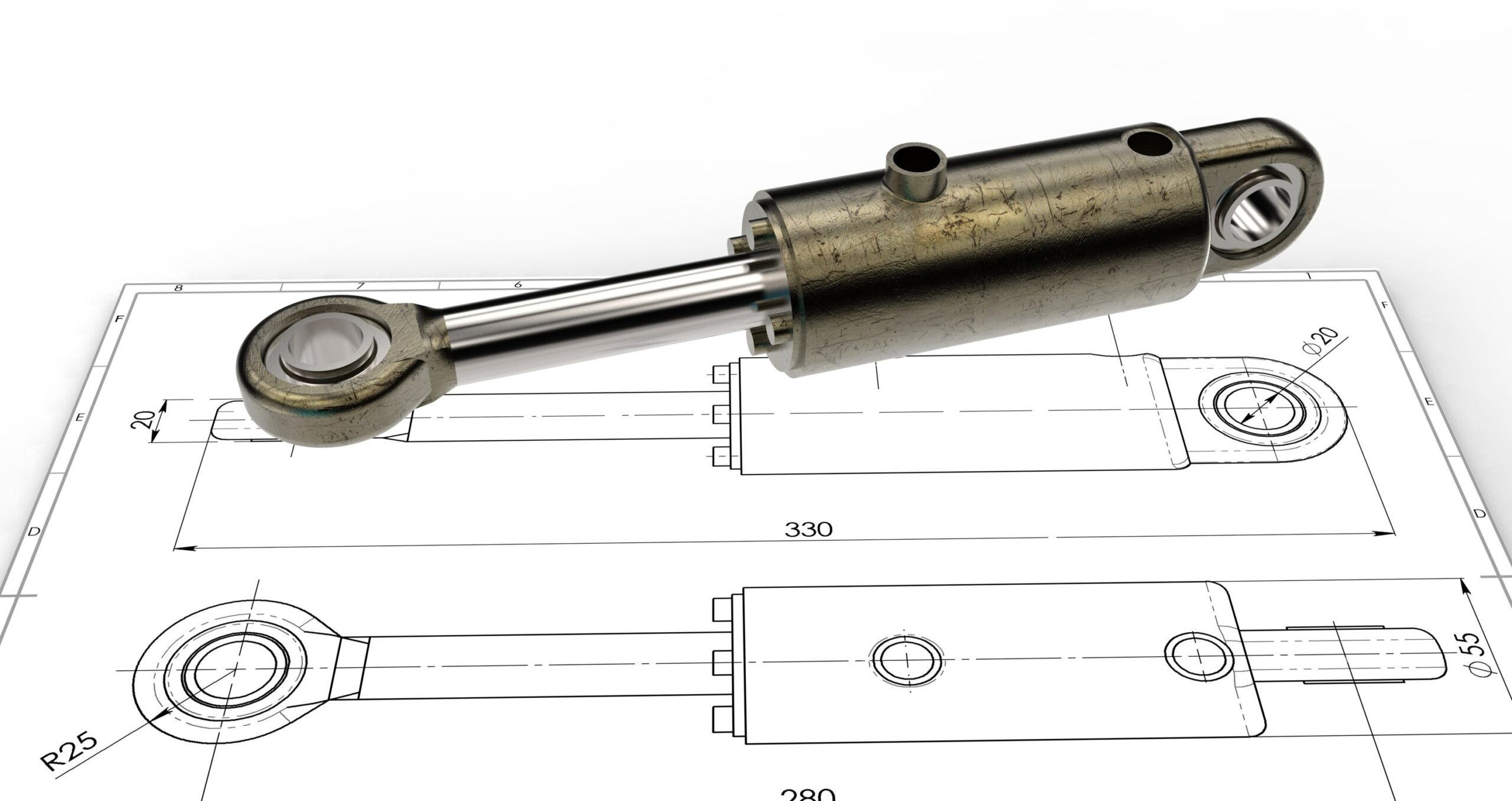

Sizing a hydraulic cylinder seal kit is a straightforward process. You need a tape measure and calipers to take measurements. Take your time and be meticulous.

Hydraulic cylinder sealsnear me

Failing wheel bearings can cause vibrations in your vehicle. You may feel a pulsating sensation in the steering wheel or even throughout the entire vehicle when the bearings are worn out.

The wheel bearings in your vehicle play a very important role in ensuring a smooth and safe ride. They enable the wheels to rotate freely while supporting the weight of the vehicle.

The extended length of a hydraulic cylinder is the distance between its pin holes when the cylinder is completely opened. Again, use your tape measure to obtain this.

Hydraulic cylinderseal Kit Catalog

Incorrect installation of wheel bearings or insufficient maintenance can contribute to premature failure. It's crucial to have your wheel bearings installed by a qualified technician and follow the manufacturer's recommended maintenance guidelines.

If you experience any steering-related issues, it's essential to have your wheel bearings checked by a professional mechanic.

Seal kits are used to close gaps between components in hydraulic cylinders. Closing these gaps is essential because seals are responsible for maintaining hydraulic pressure and preventing contaminants in fluid power systems.

In this article, we'll explore the common indicators of worn-out wheel bearings and provide insights into when it's time to seek professional assistance to replace your wheel bearings.

A drop in hydraulic pressure, an overheated cylinder, loud clunking or banging noises, and higher-than-normal shaking and vibration are all signs you need to inspect your cylinder. Other potential signs of seal failure include:

At Goodhood, our experienced technicians can inspect your wheel bearings and replace them if needed. We use only high-quality parts and offer the best customer service available.

There are many types of hydraulic cylinder rebuild kits. Each hydraulic cylinder has unique rod and bore diameters, stroke length, cylinder length, pressure flow requirements, etc. Some of the different types of hydraulic cylinder seal kits include standard, loaded lip, cast-iron piston rings, and fluorocarbon.

Common indicators of worn-out wheel bearings include unusual noises, vibrations, uneven tire wear, or steering instability. If you notice any of such signs, it's best to get your vehicle serviced by a professional mechanic right away. At Goodhood mobile auto repair services, our experienced technicians can inspect and replace your wheel bearings if needed. We use only high-quality parts and offer the best customer service available.

Simply subtract your cylinder’s retracted length from its extended length. For example, if your retracted length was 12 inches, and your extended length was 34 inches, your stroke will be 22 inches.

The piston rod is normally a chrome-plated, circular piece of hardened steel that’s attached to the piston. Measure its diameter with outside calipers.

In conclusion, recognizing the signs of failing wheel bearings and knowing when to replace them is essential for maintaining a safe and smooth ride.

Hydraulic cylinder sealsby size

If you need help selecting the right seal kit, get help from our team at Yates Cylinders. We’ve been a leading hydraulic cylinder manufacturer for over 50 years and carry hydraulic cylinder seal kits in various sizes. Some of our kits include standard, loaded lip, fluorocarbon, low-friction, and cast iron piston ring.

UniversalHydraulic CylinderSeal Kit

If you’re thinking about purchasing a hydraulic cylinder seal kit, you most likely have a few questions. In this article, we’ll outline what you need to know before you make your purchase.

When you have your bore, rod, stroke, and other measurements, reach out to us via our fast and easy online contact form, and one of our representatives will get in touch with you shortly.

When it comes to replacing your wheel bearings, it's always best to consult a professional mechanic for expert advice and assistance.

Over time, however, these bearings can wear out and fail, leading to potential hazards on the road. It's essential to recognize the signs of failing wheel bearings and know when to replace them.

Hydraulic cylinder seal kits are essential when you suddenly encounter an unforeseen failure. Some seal failures are easy to spot, such as oil leaking from around the cylinder, while others are more challenging.

Hydraulic cylinder sealsfor sale

Worn-out wheel bearings can lead to steering instability. If you feel that your vehicle is drifting or pulling to one side while driving in a straight line, it may indicate a problem with the wheel bearings. This can compromise your ability to maintain vehicle control and pose a safety risk.

The type of kit you need depends on the piston rod’s stroking speed, fluid media, fluid pressure range, and more. You must also be sure that the seals in the kit are the right size.

Ignoring the signs of bad wheel bearings can lead to further damage and compromise your safety. It's essential to recognize the signs and take action quickly by having them inspected and replaced as needed.

If you recognize the signs of a worn-out wheel bearing, it's essential to have them checked and replaced by a professional mechanic. A qualified technician will inspect your vehicle for any issues and determine whether you need to replace the bearings.

Knowing when to replace your wheel bearings is crucial to prevent further damage and ensure your safety on the road. While there isn't a specific mileage and/or time frame for replacing wheel bearings, having them inspected regularly is recommended, especially during routine maintenance checks.

Wheel bearings wear out due to several reasons, such as wear and tear due to age or excessive load. They can also fail due to improper installation or maintenance, as well as driving conditions like frequent potholes or rough terrain.

Another sign of failing wheel bearings is excessive play in the wheel. If you notice a noticeable amount of play or looseness when you try to wiggle the wheel by hand, it could indicate worn-out bearings. This play can be felt horizontally and vertically and should not be ignored.

These vibrations can negatively impact your driving experience and may indicate a need for immediate attention to prevent further damage.

Hydraulic cylinderseal kits By Size

A wheel bearing replacement cost can vary depending on the type of vehicle, the location of the wheel bearing, and other factors. On average, it can cost between $200 - $400. At Goodhood, we offer affordable and transparent prices on all of our services. Contact us for a free quote today!

The two main types of hydraulic cylinder seals are: static and dynamic. Static seals stay in one place and prevent fluid leakage in areas where there’s no movement, such as where the piston and rod join.

Hydraulic cylinder sealstypes

If you frequently drive on rough or uneven terrain, your wheel bearings may wear out faster. Off-road driving, potholes, and bumpy roads can put additional stress on the bearings, leading to premature failure.

The retracted length of your cylinder is the distance between the centers of its pin holes when the cylinder is totally closed (retracted). Your tape measure will work best for this step.

Determine your cylinder’s bore, which is the interior diameter of the cylinder. Measure bore with a tape measure stretched across the cylinder’s inner barrel.

Roller bearings are a type of bearing that utilizes rolling elements to reduce friction. These bearings typically consist of rows of rollers, rings, cages, and washers. They're used in various applications such as automotive, industrial, and aerospace applications.

One of the most prominent signs of failing wheel bearings is unusual noises coming from the wheels. As the bearings wear down, you may hear a grinding, growling, or humming sound, especially when you're driving at higher speeds. These noises are typically more pronounced when making turns. If you notice any of these sounds, it's crucial to have your wheel bearings inspected promptly.

If you notice any of the signs, such as unusual noises, vibrations, uneven tire wear, or steering instability, it's essential to have your wheel bearings inspected immediately. Ignoring them can lead to further damage to your vehicle and compromise your safety

Dynamic seals, on the other hand, are used in parts that move relative to each other. Examples of dynamic seals include piston seals, which control the motion of the cylinder; rod and buffer seals, which manage fluid leakage and lubrication; wiper seals, which keep dirt out of the system; and guide rings, which keep everything aligned and prevent wear. Together, these seals play a vital role in the efficient operation of hydraulic cylinders.

Carefully evaluate your cylinder’s hose ports, which are where you connect hydraulic lines to deliver fluid into the cylinder. Look for any signs of abnormal wear and tear and order replacement accessories, as necessary.

When wheel bearings start to fail, they can affect the alignment of the wheels. As a result, you may notice uneven tire wear. If you observe that the tread on one or more of your tires is wearing out more quickly than the others, it could be a sign of a failing wheel bearing. Regularly inspecting your tires for uneven wear patterns can help you catch potential problems early on.

8613869596835

8613869596835