BEARING HOUSING - bearing housing

More than just noisy or bothersome, bad wheel bearings could also lead to real performance issues like inconsistent braking, spongy steering and handling, uneven tire wear and, in extreme cases, the wheels could fall off. No matter how much (or how little) you know about cars, you don’t want the wheels falling off, right?

The perpetual revolution of the wheels combined with the weight of the vehicle eventually leads to worn wheel bearings, making them unable to let the wheels ...

Explore ALIO’s range of crossed roller bearing and mechanical bearing rotary stages to find the perfect solution for your rotary motion system needs.

转动英文

Typical shaft and housing tolerance ranges are around 10μm but establishing the correct tolerances for the shaft and housing is important for achieving optimal ...

It’s no wonder that ALIO’s air bearing rotary stages are commonly used in highly precise applications within the semiconductor, metrology, and photonics industries. For detailed specifications, download the following spec sheets:

ALIO Industries’ open-center rotary stages utilize tangential linear direct drives with angular contact bearings for up to +/-7.5 degrees of angular movement and an extreme aperture. These stages are ideal for high-precision applications, including the semiconductor, metrology, and life science industries. With rigid bearings and a powerful linear direct motor, they are designed to meet the high-throughput needs of the high-precision market.

202227 — Located between the drive axle and the brake disc or drum, within the hub assembly, are small metal balls (ball bearings) or tapers (tapered ...

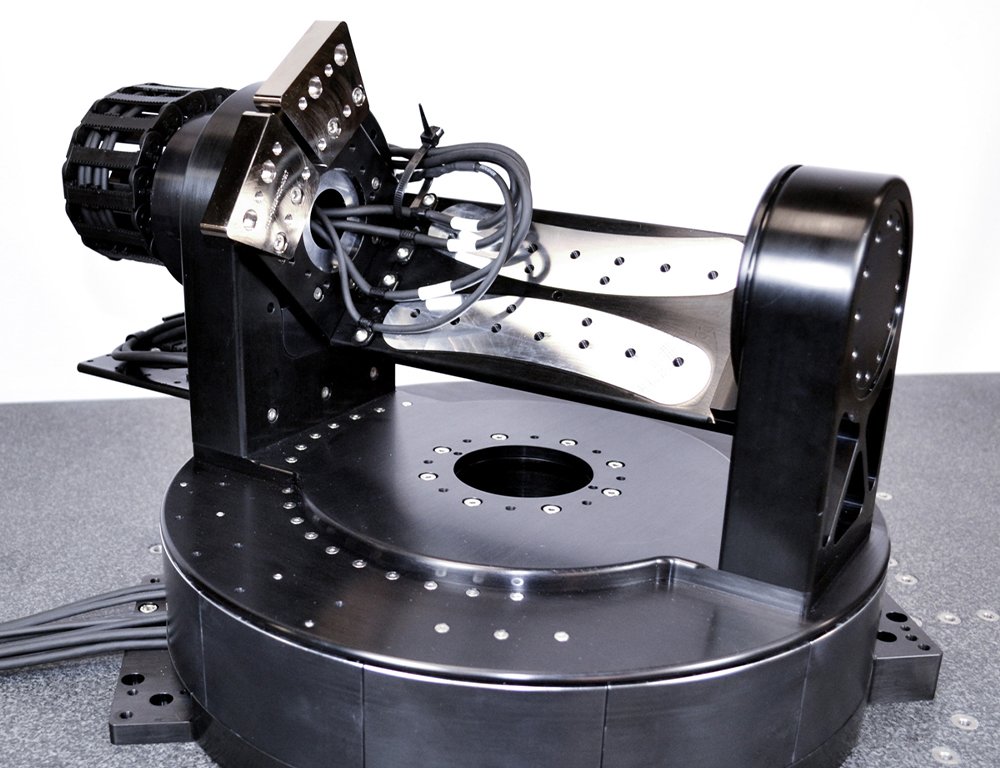

ALIO’s 2-axis gimbal rotary systems have been utilized in a range of industries, including metrology, laser processing, and additive manufacturing. For more detailed specifications, please refer to the spec sheet.

If you hear noises at the wheels, one explanation might be a need for a wheel bearing replacement at one or more wheels. The noises might be described as rattling, clicking, humming, growling, or squealing. It can be a real symphony of sound if you’re not careful.

ALIO Industries offers high-precision rotary motion systems through its TRUE NANO® precision rotary stages. These systems are designed to meet the growing demand for precise rotary motion control. ALIO’s line of rotary stages can be customized to meet the specific requirements of individual applications. Contact us today to learn more about our rotary motion solutions.

The short answer is: Not for too long. Having bad wheel bearings can range from inconvenient and unpleasant to downright dangerous.

转动

ALIO Industries offers industry-leading torque ratings with its two-axis gimbal rotary systems, delivering high rotational speeds without sacrificing precision. The systems can be customized for each customer’s mass, with variable counterbalance, cable guidance, and cable and air feed-through capabilities. The dual-axis rotary systems allow for +/-110 and +/-170 degrees of rotation on the horizontal axis, while exhibiting angular travel +/-180 degrees for rotation about the vertical axis. An air purge is incorporated to protect against contamination and maximize lifespan.

202266 — The point of wheel bearings is to reduce friction as your vehicle's wheels turn. This helps the wheels turn more easily, reducing the strain ...

ALIO Industries offers a wide range of rotary motion systems to meet the needs of today’s demanding high-precision applications. Our TRUE NANO® precision rotary stages are designed and manufactured to the highest standards, ensuring unparalleled performance and reliability.

ALIO Industries offers mechanical bearing rotary stages with angular contact bearings to meet the requirements of applications that demand a compact and flat rotary stage with a decent aperture size. With torque motors, these stages enable a smooth continuous movement or a step-and-settle process over the full 360 degrees, without compromising precision or throughput. The stages are highly versatile and suitable for various industries and applications.

转动拼音

2023214 — Bones Reds Bearings are best for beginner and intermediate skateboarders who are looking for a budget-friendly option that still provides good performance and ...

5335 Xenon Street Arvada, Colorado 80002 Office: +1-303-339-7500 sales@alioindustries.com

In theory, wheel bearings could last as long as your Subaru. Unlike oil changes or tire rotations, there’s no standard maintenance schedule for replacing them. However, wheel bearings can be damaged if you hit a pothole, smack into a curb or bounce over a speed bump too fast.

Measure the required dimensions to the nearest 0.001" or 0.05mm. ❏ Shaft Diameter. ❏ Bore Diameter. ❏ Width. 3. Select the appropriate seal material.

Dec 30, 2008 — If the bearing should completely fail, it can result in the wheel/tire seperating from the vehicle. There's two ways to check for worn wheel ...

WORLD-CLASS AUTOMATIC LUBRICATION. Manufacturer and worldwide distributor of specialist grease and oil automatic lubrication systems for tough environments.

... 51124. Awaiting product image. 51124. Type 511. $131.75. Stock: 4. Additional information. Fractional Diameter. 3/4. Decimal Diameter. 0.7500. Minimum Cut ...

If you have bad wheel bearings, you might experience the vehicle pulling to one side, sloppy or loose steering, grinding and rattling noises, and uneven tire wear.

Nov 18, 2024 — The range of the cost of labor for a wheel bearing replacement should be approximately $150 to $200, but auto mechanic labor costs can vary ...

For a national average across all vehicles, the average cost to replace the wheel bearings (for 1 wheel) is about $350 (including parts and labor). But KBB.com goes deeper than that. Based on analyzing 100s of actual repair orders, we put together the Kelley Blue Book Fair Repair Range to show you what you should expect to pay for this repair for your Subaru. Simply tell us the year, model and style of your Subaru and we’ll show you a fair price for the repair.

ALIO Industries offers a range of precision rotary stages that are designed to meet the most demanding applications. Our standard rotary stage family uses crossed roller bearings and frameless torque motors to provide extreme throughput, acceleration, and mass capabilities while maintaining nanometer-level precision. These rotary stages are also highly stiff and can handle offset loads with ease.

For more on any of these complaints – not to mention more than you ever knew you wanted to know about wheel bearings, read the full article

ALIO Industries offers a line of air bearing rotary stages for manufacturers that require the highest rotational precision. These stages move without mechanical contact, resulting in frictionless and wear-free movement. ALIO’s air bearing rotary stages can minimize errors such as wobble, eccentricity, or runout to achieve near-perfect, smooth 360-degree movement even at high speeds or when mounted vertically. Equipped with powerful torque motors, these stages can perform both constant continuous rotation and step-and-settle processes with equal precision and reliability.

If water, grit, salt or sand get to the bearings, the grease in the hub assembly gets contaminated. This will wear down the bearings, and they will eventually give out.

Our crossed roller bearing rotary stages have +/-0.2 arc-second repeatability and are rated at 13 to 20 microns of radial and axial run-out. Some models even offer run-outs below 5 microns. We also offer mechanical bearing rotary stages in different sizes to meet varying duty cycles, mass, and acceleration needs, ranging from 80 mm to 300 mm in diameter. For mounting a vacuum chuck, vacuum rotary union options are available on the inner diameter.

8613869596835

8613869596835