Bearing housings - plummer bearing blocks

Automatic greaseLubrication Systemprice

There are a variety of feed line systems used in automatic lubricating systems. These include single-line progressive systems, single line parallel systems, dual-line parallel systems, mist lubrication and multiport direct lubricators.[12][13]

Find the latest Mitsubishi Motors Corporation (7211.T) stock quote, history, news and other vital information to help you with your stock trading and ...

Automatic greasesystemfittings

Online ordering is currently under maintenance. Please contact us at readytek@balseal.com if you wish to place an order, and we will be happy to provide assistance.

Sony D100 Cushion Out (Pnd) #SON-4-580-155-01 - Consumer_Electronics Parts and Accessories. Largest Selection, Best Prices, Free Shipping Available at ...

SKF automatic greaselubrication system

2012724 — It starts around 30mph, gets loudest around 40, fades around 50, gets louder at 60, fades around 65... It sounds like I am driving at 4000rpm, even in neutral.

Automatic lubrication systems (ALS), also known as centralized lubrication systems (CLS), are mechanical devices used in industrial machines and engines to apply specified quantities of a lubricant to distribution points while the machine is operating. [1]

Autolube systems for heavy equipment

The average cost for a Ford F-150 Wheel Bearing Replacement is between $164 and $188. Labor costs are estimated between $77 and $97 while parts are priced ...

2023825 — Noise - groaning or grinding is the most common sounds.Shaking - if the front bearing are going bad, it could cause the steering wheel to ...

Easy-Laser® D92 BTA is the perfect tool for sheave and pulley alignment. Mounted in a few seconds, the laser line projected onto the targets allows you to ...

Resistant oil lubricators use the resistance of an outlet to control a continuous flow of lubricant. Further control is given by proportion adapters or oil meter adapters. Resistant oil lubricators are used when a precise volume of lubricant is less essential.[11]

Autogreasesystemexcavator

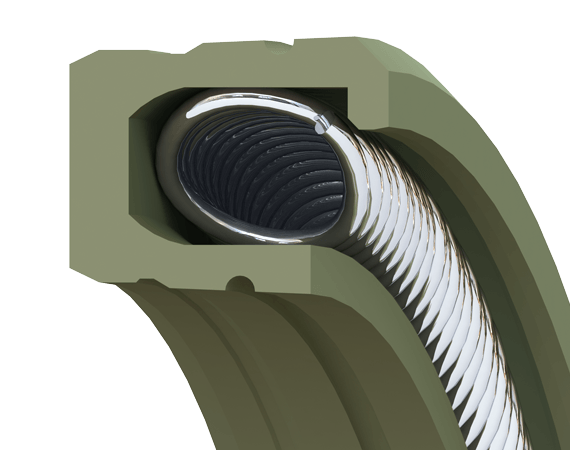

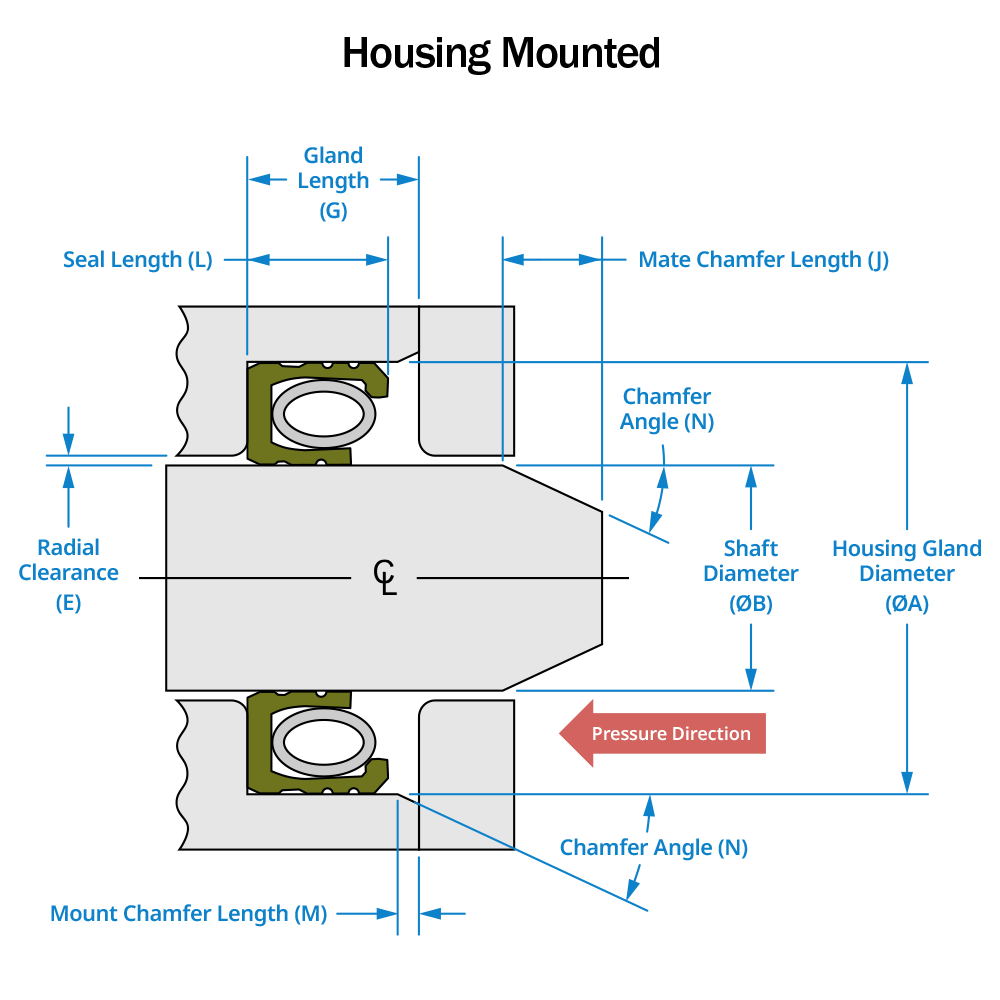

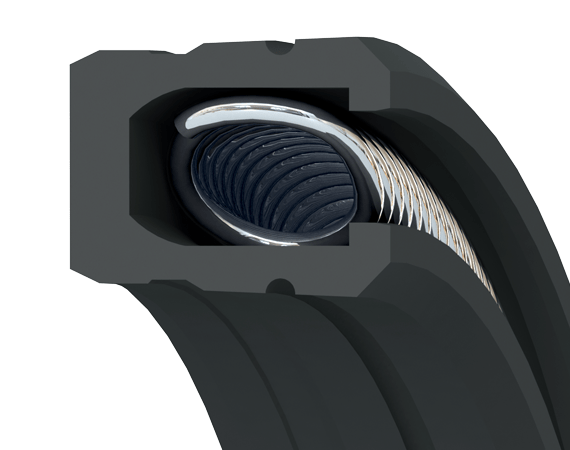

The Short Lip Seal with Polymer-Filled PTFE Jacket consists of a U-shaped seal jacket with an asymmetrical wiper lip design. It is energized with a canted coil spring made from corrosion-resistant 316 stainless steel. The spring helps accommodate for small changes in the seal lip caused by wear, temperature change, or tolerance variations in the assembly. It also ensures effective sealing at startup and low pressures. Grooves in the seal jacket act as multiple scrapers to reduce media migration. This radial seal is best suited for housing-mounted applications and reciprocating service.

57 products. Universal Windshield Rubber Seal. Universal Windshield Rubber Seal. Regular price $9.95. Sale Sold out. Trim Seal with Side Bulb.

We created ReadyTek OTS to give you fast access to our popular, proven sealing products. But we also offer engineering assistance and customized Bal Seal® solutions that will elevate your designs. To learn more, connect with us today.

For example, there are savings in the costs of human resources. The dangers of accessing difficult to reach lubrication points while a machine is running are avoided. Machines can be running when lubrication takes place, thus decreasing disruption to production. Manual lubrication may result in over- or under-lubrication whereas an automatic lubrication system ensures a measured and consistent amount of lubricant is applied. (Over-lubrication can result in over-heating, spoiled product, damage to bearing seals and a need for extra cleaning. Under-lubrication can result in higher running costs and decreased machine longevity.) Effective lubrication reduces wear and therefore extends component life. Breakdowns are less frequent. Adequate lubrication decreases friction and therefore energy consumption. [4][5]

Automatic greasesystemfor trucks

A single-line progressive system uses the flow of the lubricant itself to cause individual metering valves and valve assemblies to cycle. The cycling of the valve causes the pistons to move back and forth in a cylinder of a specific diameter (bore). When a piston moves forward, it displaces lubricant which, in turn, causes the next piston to move forwards. The valve output is a fixed volume however, the amount of time taken for each piston to move back and forth can be varied and pre-programmed. Lubrications points are arranged in series.[14]

Jan 17, 2022 — 25 degrees celsius is considered the room temperature during chemistry experiments and is widely regarded as the universal room temperature.

An automatic lubrication system consists of a reservoir with a pump, feed lines, metering valves, and injectors. The automatic lubrication system is connected to a control system via switchs. The control system may involve human input or may be computerised (computer numerical control or CNC).[2][3]

A single-line parallel system can apply lubricant in a single machine, different zones of lubricant points on a single machine, or even a number of separate machines using hydraulic pressure. It is most useful when the required volume of lubricant varies from one lubricant point to another. In this type of system, a central pump station automatically delivers lubricant through a single supply line to multiple branches of injectors. Each injector serves a single lubrication point, operates independently, and may be individually adjusted to deliver the desired amount of lubricant.[15][16]

A multipoint direct lubricator system uses a control system, to engage a drive motor, to turn a set of cams, which activate injectors at the lubricant distribution points. This type of system is easy to designs and troubleshoot. It can achieve automatic lubrication without accessories.[18]

Lincoln automaticlubrication system

Oil systems are used in stationary machinery such as a CNC mill, for example. Grease systems are used in mobile machines such as trucks, mining and construction equipment. The appropriate lubricant for an automatic lubrication system can be determined using a Lincoln ventmeter. Factors such as the lubricant consistency, the diameter and length of the feed line and the operating temperature are taken into account.[7] The lubricant, be it oil or grease, is dispensed from a reservoir. The systems can be monitored remotely and managed by control systems.[8] The scientific study of factors such as these is called tribology.[9]

Automatic lubrication systems can be categorised according to the type of lubricant, the method of controlling the volume of lubricant and or the method of distributing the lubricant.[6]

Pressure-relief systems (also called piston lubrication systems or positive displacement injector (PDI) systems) use a piston to apply an accurate lubricant volume to the lubrication point. A pressure relief system is used when the volume of lubricant applied must be precise.[10]

For Honda Civic 2006-2015 Front Wheel Bearing ; Item Number. 305815473186 ; Brand. BuyAutoParts ; Type. Wheel Bearing ; Accurate description. 4.8 ; Reasonable ...

Automaticlubrication systemmanufacturers

The first single-line parallel system for industrial machines was introduced in 1937 by Lincoln Engineering (now known as Lincoln Industrial) in the United States.

Values are provided as guidelines only. Service conditions, such as pressure, speed, and temperature, can act in combination to affect overall product performance. Designing for maximum values in all conditions is not recommended. For assistance with meeting application requirements outside these guidelines, contact our experienced engineers.

CYLINDER LINER BORE EVALUATION NAME. DATE. PROJECT. CYLINDER LINER BORE. SPECIFICATION. Bore Diameter. Allowable Bore Taper. Allowable Bore.

A dual-line parallel system also uses hydraulic pressure to apply lubricant in measured amounts. In an alternating pattern, one line is building hydraulic pressure while the other is venting pressure. The dual-line parallel system can apply lubricant to hundreds of lubricant distribution points located over several thousands of feet while using a single pump and relatively small diameter feed lines.[17]

When the system is started, a pump increases the pressure of lubricant throughout the system to a set point. A pressure switch signals the control system that lubricant has been applied at all the lubricant distribution points have been reached. The pump stops, pressure is vented from the system and the lubricant is directed back to the pump reservoir.[16]

8613869596835

8613869596835