Bearing Pullers - Jaw, Mechanical, Hydraulic, and Strong- ... - bearing pullers

The best way to figure out the cause of this noise is to check the tires first. If the tires look good, then check the wheel bearings.

If you have already read the articles on angular contact ball bearings or tapered roller bearings, you may already have come into contact with different types of bearing arrangements. Specifically, these refer to the arrangement of the rolling elements in multi-row or matched bearings. There are three main types – O, X and tandem arrangements.

It can be hard to figure out if the noise is caused by a wheel bearing or a tire. There’s something you can try, though. Turn the steering wheel slightly to the left or right. If the noise gets worse, then it’s likely one of the wheel bearings.

Frontwheel bearingnoise symptoms

In contrast to the O arrangement, there is only one possibility here: A temperature difference between the inner ring and the outer ring leads to a reduction of the clearance or to an increase in the preload in the bearings. The extent to which these effects are critical for the bearing arrangement can be determined either from empirical values or through extensive and costly tests. In practice, costly tests can be avoided by asking the bearing manufacturer for advice.

In extreme cases, a failed wheel bearing can cause abnormal tire wear. When that happens, the noise you’re hearing is caused by both a bad wheel bearing and a worn tire.

In the following, the three temperature effects that exist in the O arrangement and the so-called rolling cone peak R will be discussed. The latter can be seen in the three case studies shown.

If you’re hearing this noise, the issue may be a bad wheel bearing. To confirm it, change the speed of the vehicle. If the noise becomes worse the faster you drive, then it’s almost certainly a bad wheel bearing. If the noise remains the same, then the issue may be the tires instead.

Wheel bearingnoise test

If the problem is a worn wheel bearing, then you’re hearing a knocking noise because the bearing isn’t rotating as freely as it should. A bad tire can cause a knocking or thumping noise, too. To be more specific:

Bearing clearance and operating clearance, isn’t that the same thing? And preload, I’ve heard that before, but what is that supposed to be?! How do

In such cases, one adds one or two bearings to an O-arrangement (see illustration of the bearings of a CNC milling machine spindle). The two bearings on the left are in tandem. The bearing arrangement shown is therefore called a tandem O arrangement. In contrast to the “simple” O or X arrangements, such tandem arrangements can support a greater axial load in one direction (acting from left to right in the picture). This reduces the axial deflection compared to the simple O-arrangement.

Let’s start with the O arrangement, the questions of what it can do and when you should use it. In the article on adjusted bearings, it was already mentioned that angular contact ball bearings and tapered roller bearings can be “adjusted” to form an O arrangement. This means that in addition to high radial loads, axial forces from both directions can also be accommodated.

We put together this noise guide to save you some labor time. You can have your technicians find the noise that best describes what they’re hearing in the list below. From there, they may be able to figure out what the issue is.

Interference fit, transition fit, clearance fit. You should know and be able to define these three types of fit after reading this article. But before

The noise may be the result of an under-inflated tire or improperly aligned tires. These issues cause part of the tires (or one tire) to be scrubbing on the pavement. That causes a squealing noise.

Wheel bearingnoise quick fix

In addition to single-row angular contact ball bearings, which can be arranged in an O arrangement, there are also double-row angular contact ball bearings, for example. These are supplied in an O arrangement and have a common outer ring and inner ring. The advantage of these double-row angular contact ball bearings is their width.

If the wheel bearing and tires look good, you may want to check the drivetrain. Sometimes a humming or growling noise is a sign of an issue within the drivetrain.

The angular contact ball bearing is virtually the brother of the deep groove ball bearing. Characteristics of angular contact ball bearings Perhaps you already know

What do you do when a customer brings you a vehicle with a roaring or howling noise coming from a wheel? In most cases, it can be coming from a worn tire, or a worn bearing. It is not easy to tell, but there are ways to determine what is causing the problem.

You may also trace this noise to a loose pinion-bearing preload. It’s likely the case when you only hear the noise when decelerating.

To explain when to use the O arrangement, the following example can be given: In an application, two 6212 deep groove ball bearings were previously used, but a more rigid support of the shaft is now required. What is the best way to proceed? In the sketch you can see two angular contact ball bearings. The value a must be used, which indicates the support span. For a 7212 angular contact ball bearing (30° contact angle) the value is a = 36 mm. For a 7212B angular contact ball bearing (40° contact angle) the value is a = 47,5 mm. In comparison, the previously used 6212 deep groove ball bearing only has a span of 11 mm (half the bearing width). If the two 6212 deep groove ball bearings are now replaced by angular contact ball bearings 7212B, this results in a considerably larger support span and consequently also a more rigid support of the shaft.

Wheel bearingnoise dangerous

If you’re still not sure whether the issue lies in the tires or one of the wheel bearings, check out the most common symptoms of each issue:

Generally speaking, a bearing is only as good as its environment. Who can perform at their best if they don’t feel comfortable in their surroundings?

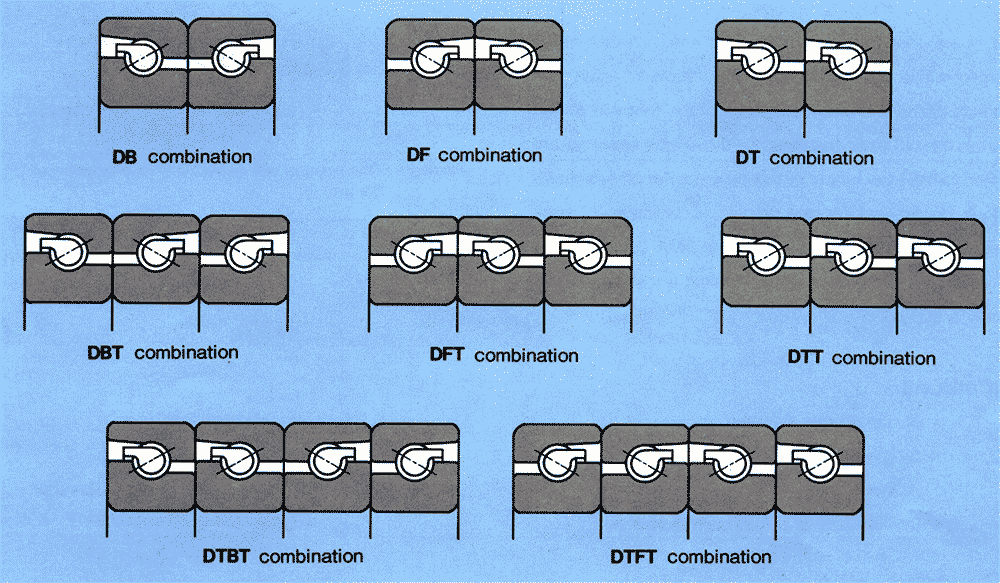

Applies to angular contact ball bearings and tapered roller bearings O-arrangement: Only small misalignment of the bearings possible, wide support base X-arrangement: Larger misalignment of the bearings possible, low support base Tandem arrangement: Unlike the other two arrangements, bearings can support axial loads from only one direction All arrangement types can be combined with each other

SNR Wälzlager GmbH creates the information for this website with great care and endeavors to ensure that it is up-to-date, correct and complete. SNR Wälzlager GmbH assumes no liability and is not liable for any material or immaterial damage caused by the use of the service, unless it can be proven that it was caused by intent or gross negligence.

Wheel bearingnoise when accelerating

Angular contact ball bearings as well as tapered roller bearings with rolling elements in X arrangement can support axial forces running in both directions in addition to high radial loads (just as with O arrangement). Bearings with an X arrangement have a smaller support span between the load application points compared to bearings with an O arrangement. The load directions therefore intersect on the shaft axis, which is why bearings in this arrangement have a lower moment rigidity. At the same time, the X arrangement has a lower tilting rigidity, which means that larger misalignments are possible. The use of such bearing arrangements is suitable, for example, in the case of shaft deflection or in the case of predominant radial force application between the bearing points.

If the issue is a worn wheel bearing, you’d typically hear this noise while cornering or making sharp turns with moderate speed. A bad CV joint can be heard at low speeds with the steering wheel all the way to one side or the other. It can’t hurt to check both the wheel bearings and CV joint(s).

If you’re replacing a bad wheel hub bearing, you want to make sure that your techs use high quality replacement parts. Using high quality replacement parts:

A worn wheel bearing can cause a howling noise. If you’re also hearing a rumbling noise when turning, then it’s likely a bad wheel bearing.

A 7200B bearing (B = 40° contact angle), for example, has a width of 9mm, so the O arrangement thus has a bearing width of 18mm. The double-row angular contact ball bearing 5200S has an overall width of 14.3mm with the same bore and outer diameter and is thus narrower in design. However, the load ratings are lower compared to the single-row angular contact ball bearings, so a compromise must be found. In addition, there are also double-row tapered roller bearings.

Wheel bearingreplacement cost

OK, and what does that mean? The bearing has been designed and deflections, bending lines, gear corrections etc. have now been calculated. However, if the temperature effects have not been taken into account, the consequences can be serious. In the worst case, bearing damage can be the result. Should this occur in practice, it is advisable to contact the bearing manufacturer for support.

Do I choose a fixed bearing arrangement, an adjusted bearing arrangement or a floating bearing arrangement? This question is important when designing a shaft system.

This post will help you find a quality parts manufacturer. GMB is a reliable manufacturer of OE-quality hub assemblies and wheel bearings. Check out this page to find out why GMB wheel bearing and hub assemblies are the prime choice.

For some applications (especially for bearings in machine tools), several bearings are needed to “absorb” the acting forces and to achieve the desired properties (service life, rigidity, etc). This is why you also come across various combinations of individual bearings. In order not to have to write long, almost complicated designations such as Tandem-O or Tandem-O-Tandem arrangement every time, the whole thing is abbreviated with initials (like with O and X arrangement).

Characteristics of tapered roller bearings Here you see an NTN tapered roller bearing. As the name suggests, tapered roller bearings are roller bearings, whereby the

If the noise is more “growly”, then the issue is likely a bad wheel bearing. The noise may become louder the faster you drive.

The O, X and tandem arrangement is about how several bearings are arranged in relation to each other. If you look at the contact angles of the force application in the technical drawings and sketch them further in your mind, you will notice that they take on an O-shape in the O-arrangement and a – surprise! – X-shape in the X arrangement. The tandem arrangement can be visualised insofar as the contact angles in the drawing work in the same direction. Also, the tandem bicycle can serve as a mnemonic. Before you read about specific characteristics, you should know that there are several names for the different arrangements.

Applies to angular contact ball bearings and tapered roller bearings O-arrangement: Only small misalignment of the bearings possible, wide support base X-arrangement: Larger misalignment of the bearings possible, low support base Tandem arrangement: Unlike the other two arrangements, bearings can support axial loads from only one direction All arrangement types can be combined with each other

8613869596835

8613869596835