Bearings Size Chart - RHD Bearings - roller bearing dimensions

Brenco bearing

This document does not apply as an alternative to ISO 5349-1. The data derived from this document does not apply to perform tasks in accordance with national regulations, guidelines or recommendations for workplace vibration or machinery vibration emissions. This document does not apply to the legal obligations related to the protection of workers from hand-arm vibration in the workplace and the declaration of vibration emissions from machinery.

NTNbearings

The classic TBU for American freight car bogies is designed with inch size dimensions following the standards of the Association of American Railroads (AAR).

Amsted Rail manufacturing locations

The methodology defined in this document is based only on biomechanical relationships between vibration transmission to the hand-arm system as a function of total forces. The influence of contact force and pressure on the surface of the hand remains unconsidered and requires further research.

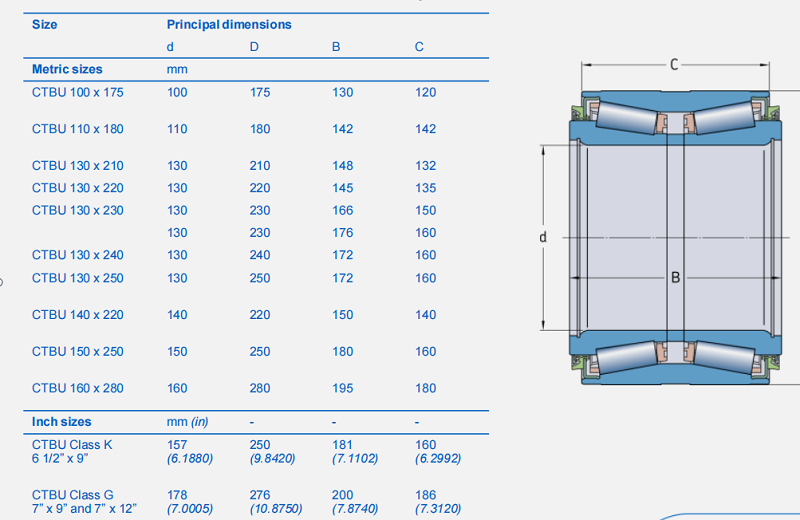

For new freight cars with increased cargo, inch size compact tapered roller bearing units (CTBUs) are used. The sealing system of the CTBU consists of two parts: a (stationary) seal that is anchored in the outer ring and a flinger ring that is fitted directly on the inner ring shoulder. This design offers increased reliability.

This document provides guidance on an additional procedure to that defined in ISO 5349-1 for measuring and reporting hand-transmitted vibration exposures by taking into account the coupling force exerted on the vibrating surface.

This document describes a coupling-force-dependent weighting of the r.m.s. value to the frequency-weighted acceleration, ahw.

Railroad bearingscatalog

All ISO publications and materials are protected by copyright and are subject to the user’s acceptance of ISO’s conditions of copyright. Any use, including reproduction requires our written permission. All copyright requests should be addressed to copyright@iso.org.

Railway axlebearings

Tapered roller bearing units (TBUs) consist of two inner rings with a tapered roller and polymer cage assembly, a common outer ring, a central spacer, two sealing systems and a grease fill.

The procedure only applies to normal gripping situations (embracing a handle). If only part surfaces of the hand are exposed to vibration, the procedure is not applicable.

Rail Manufacturers in USA

Amsted Rail

We offer solutions for a wide range of wheelset designs for all kinds of railway rolling stock. This includes high-speed trains, diesel and electric locomotives, diesel and electrical multiple units, passenger coaches, freight cars and mass transit vehicles like tram cars.

This standard contributes to the following Sustainable Development Goals 9 Industry, Innovation and Infrastructure 8 Decent Work and Economic Growth

This document is intended to facilitate future research on hand-arm vibration risks and to complement data collected using the ISO 5349-1 methodology.

This document describes a coupling-force-dependent weighting of the r.m.s. value to the frequency-weighted acceleration, ahw. The procedure only applies to normal gripping situations (embracing a handle). If only part surfaces of the hand are exposed to vibration, the procedure is not applicable. The evaluation methods defined in this document are intended to enable research. This document provides guidance on an additional procedure to that defined in ISO 5349-1 for measuring and reporting hand-transmitted vibration exposures by taking into account the coupling force exerted on the vibrating surface. This document is intended to facilitate future research on hand-arm vibration risks and to complement data collected using the ISO 5349-1 methodology. This document does not apply as an alternative to ISO 5349-1. The data derived from this document does not apply to perform tasks in accordance with national regulations, guidelines or recommendations for workplace vibration or machinery vibration emissions. This document does not apply to the legal obligations related to the protection of workers from hand-arm vibration in the workplace and the declaration of vibration emissions from machinery. The methodology defined in this document is based only on biomechanical relationships between vibration transmission to the hand-arm system as a function of total forces. The influence of contact force and pressure on the surface of the hand remains unconsidered and requires further research.

We are committed to ensuring that our website is accessible to everyone. If you have any questions or suggestions regarding the accessibility of this site, please contact us.

8613869596835

8613869596835