BMW 3 Series Rear Wheel Bearing (One) Replacement cost - how much for rear wheel bearing replacement

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

Copyright © 2023 NEI Ltd. All rights reserved. Registered Office : 9/1, R. N. Mukherjee Road, Kolkata – 700 001. In case of any queries or grievances, please contact Mr.Tarun Kumar Kabra, Company Secretary. E-mail: neical@nbcbearings.in Privacy Policy Cookie Policy

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

Brand Name: B&K Mueller *End 1 Diameter: 1-1/2 in. *End 1 Type: MPT *Finish: Galvanized *Material: Steel *Length: 6 in. *Product Type: Nipple *Average Lead ...

Bearing manufacturers primarily use high-quality alloy steels, such as chrome steel (52100), stainless steel, or ceramic materials, for bearing manufacturing. These materials offer excellent wear resistance, hardness, and fatigue strength, making them ideal for demanding industrial applications.

Turning and grinding are essential processes in bearing manufacturing, where the blanks are further refined to meet tight tolerances and surface finish requirements. Turning involves machining the outer and inner ring surfaces to achieve precise dimensions and concentricity, while grinding utilizes abrasive wheels to achieve the required surface finish and roundness.

Bearingmanufacturing process PDF

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

The manufacturing process of bearings is a fascinating journey that involves precision engineering, advanced technologies, and meticulous attention to detail. In this comprehensive guide, we’ll take you through each step of the typical bearing manufacturing process, from the selection of raw materials to the assembly of precision components. Whether you’re a seasoned industry professional or a curious student of mechanical engineering, join us as we delve into the intricacies of bearing production and explore the technologies driving innovation in this critical sector.

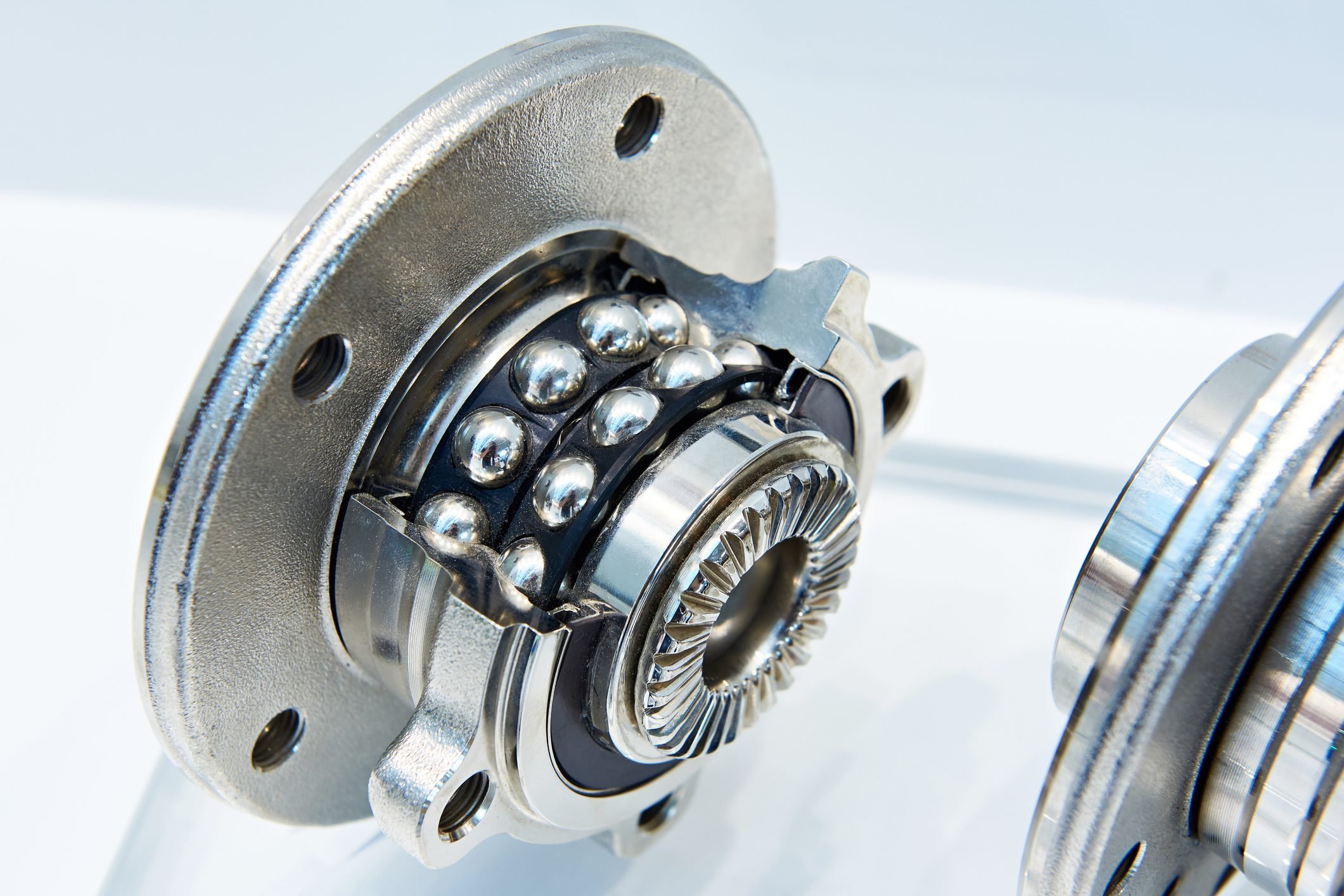

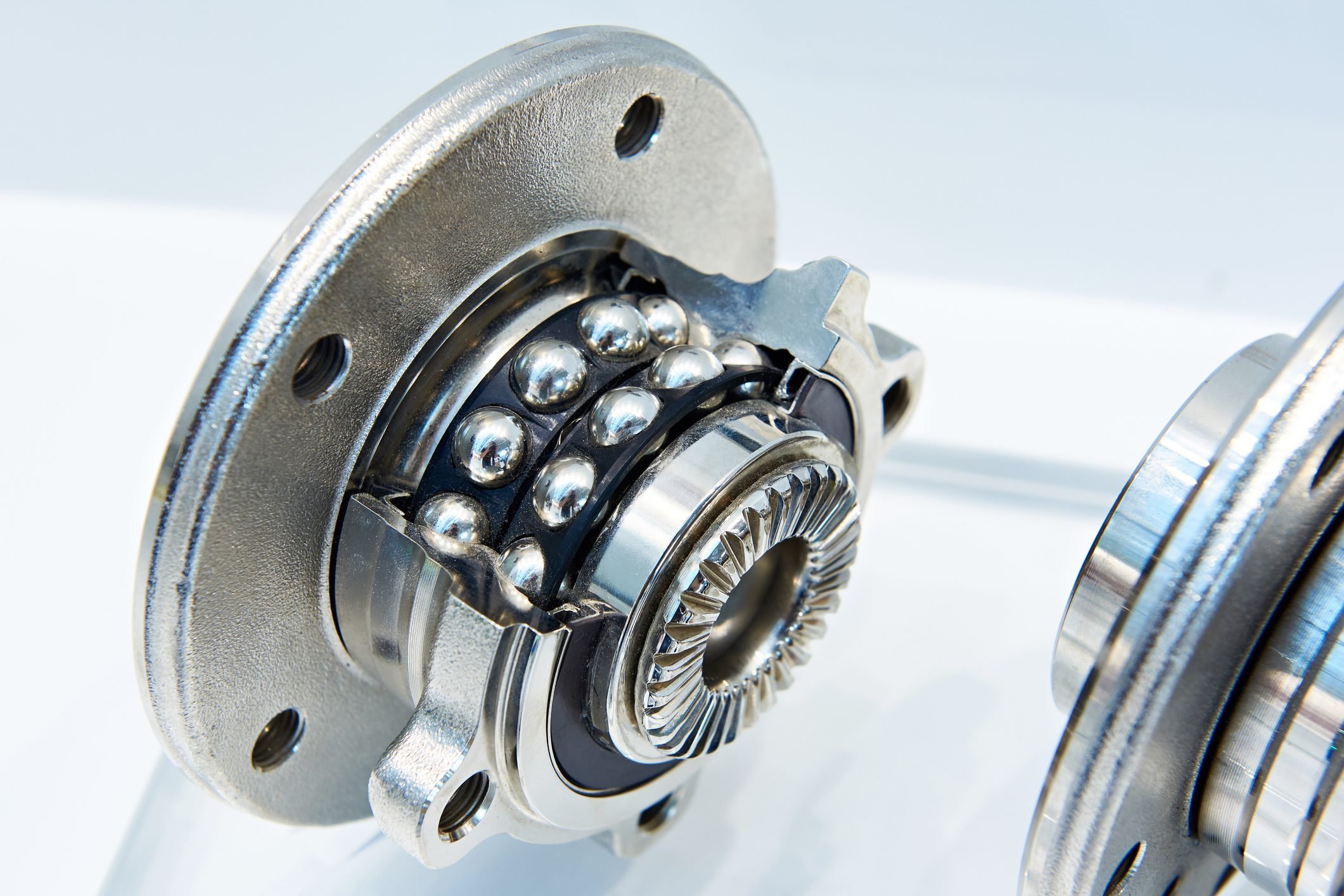

Howare steel ballsmade

Once the individual bearing components are machined to specification, they are assembled into complete bearing units. This assembly process may involve press-fitting the inner and outer rings onto the rolling elements, installing cages or retainers, and applying seals or shields to protect the bearings from contaminants.

Rod ends are mechanical articulations that allow for angular misalignment between connected components. They typically consist of a spherical plain bearing, ...

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

In addition to traditional machining and assembly techniques, bearing manufacturers are increasingly incorporating advanced technologies such as CNC machining, robotic automation, and digital inspection systems to improve efficiency, precision, and quality control in the manufacturing process.

How a ball bearing is madefrom steel

These technologies enable faster production cycles, tighter tolerances, and enhanced product consistency, ensuring that bearings meet the demanding requirements of modern industrial applications.

Overview: The manufacturing process of bearings begins with the careful selection of raw materials and progresses through various stages of machining, heat treatment, and assembly. Each step is critical to ensuring the final product meets stringent quality standards and delivers optimal performance in a wide range of applications.

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

Howare roller bearingsmade

Bumpass VA ZIP Code 23024 Profile, Interactive Map, Demographics, Income, Economy, Housing and School Attendance Areas.

Assembly automation plays a crucial role in streamlining the production of various bearing types. Automated assembly systems utilize robotics, conveyors, and vision systems to efficiently assemble bearing components with high speed, accuracy, and repeatability. By automating repetitive tasks and minimizing human intervention, assembly automation improves productivity, reduces labor costs, and ensures consistent product quality.

Front Wheel Bearing and Hub Assembly fits 2007-2011 Jeep Wrangler ... Pay $87.78 after $25 OFF your total qualifying purchase upon opening a new card. info. Apply ...

Founded in 1946, National Engineering Industries Ltd (NEI) is India’s leading bearings manufacturer and exporter, renowned for excellence in quality and delivery.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

How a ball bearing is madestep by step

Hi! Why are these types of bearings good at absorbing axial loads? Are other bearings bad at it? Thanks!

Buy Aluminium oxide hydrated - 64% Al2O3 FA34389 24623-77-6 online for pharmaceutical testing. High-quality reference standards for accurate results.

Depending on the bearing type and design, the blanks may undergo forging or turning processes to achieve the desired shape and dimensions. Forging involves shaping the blanks under high pressure and temperature to improve the material’s strength and structure, while turning uses precision machining techniques to achieve precise dimensions and surface finishes.

Enhance your running gear with options like '25580 Timken Bearing' and 'L44649 Timken Bearing'. Shop now to upgrade your trailer parts with top-quality Timken ...

Howare bearingsmade

Triangle is an industrial stamped rod end bearing supplier for lawn & garden, recreation vehicles, solar & more. Light weight with lower costs and ...

... -----------------------------. Request for interest(RFI) to sell strategic stake in Uranium Mines to Uranium Corporation of India Limited, India.

The user must be an administrator, editor, or moderator of the page in order to impersonate it. If the page business requires Two Factor Authentication, the user also needs to enable Two Factor Authentication.

A symbol of dependability and flexible engineering solutions, NBC Bearings is the brand of National Engineering Industries.

Howareballbearings assembled

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Howareballbearingsmadeperfectly round

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

Among the various types of bearings, ball bearings are the most commonly used due to their versatility, high load-carrying capacity, and relatively low friction. Ball bearings are widely used in a wide range of applications, including automotive, industrial machinery, and consumer electronics.

Once the raw materials are selected, the manufacturing process begins with bar stock cutting. This involves cutting cylindrical bars of steel or other materials into smaller pieces, known as blanks, that will serve as the starting material for the bearing components.

The quality and performance of bearings depend largely on the raw materials used in their construction. Bearing manufacturers typically use high-quality alloy steels, such as chrome steel (52100), stainless steel, or ceramic materials, selected for their excellent wear resistance, hardness, and fatigue strength.

Lubrication plays a critical role in ensuring smooth operation and extending the lifespan of bearings. During the manufacturing process, bearings are lubricated with high-quality lubricants, such as grease or oil, to reduce friction, dissipate heat, and protect against wear and corrosion.

The basic concept of a bearing is to reduce friction and facilitate smooth motion between two surfaces by providing support and guiding moving parts. Bearings typically consist of rolling elements (such as balls or rollers), enclosed within an outer and inner ring, and separated by a cage or retainer.

Customized: Customized ; Certification: ISO, BV ; Standard Parts: Yes ; Universal: Yes ; Type: Bearing Ball ...

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

8613869596835

8613869596835