Bush Dust Seal - Excavator - lucas parts - pin seals

Radial bearingexample

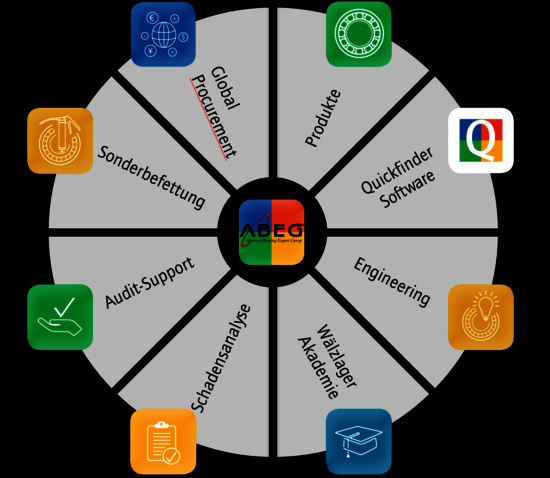

DevelopmentQuality laboratoryGlobal ProcurementE-ProcurementAudit SupportABEG QuickfinderSpecial greasingDamage analysisAcademyLogistics

What is aradial bearingin surveying

If you want to know how to check for a bad wheel bearing, place your car on a jack stand, grip your hands on the 6 and 12 o’clock positions of the tire, and then spin the wheel to see if it wiggles. It’s also a great way to learn how to tell which wheel bearing is bad.

Thrust bearingexample

Additional installation space can be saved when using radial/thrust bearings without an inner ring or counter washer. In this case, the shaft serves as a raceway. However, to maintain full load carrying capacity, it has to be hardened in the 58-64 HRC range. Values below 58 HRC are also possible, but this reduces the static and dynamic load rating of the bearing. For example, at a hardness of 52 HRC, the dynamic load rating of the bearing would decrease by a factor of 0.73 and the static load rating would decrease by a factor of 0.96. The load rating ranges go from 2,100 N radially dynamically and 1,900 N statically up to 37,000 N radially dynamically and 86,000 N statically. Axially, the load rating extends from 3,100 N dynamically and 6,300 N statically to 77,000 dynamically and 294,000 statically. The boundary speed range covers 3,000 rpm up to 25,000 rpm. It is also possible to acquire the bearings as precision roller bearings. In this case, a stronger outer ring is used that has a front side which serves as a raceway for the axial part of the bearing. This allows bearings that are axially very rigid and free of play to be created, which are required, for example, in the drive spindles of measurement systems or machine tools.

Most people are aware of the need for general car maintenance. It’s essential to take care of the basics, like regular oil changes and checking battery terminals for corrosion. But, getting an alignment is just as important. Many think it’s simply a minor irritation when your alignment starts to get off. The truth […]

Combined radial/thrust bearings hold a special position among rolling bearings: They are capable of simultaneously handling very large radial and axial forces and are characterized by their particularly compact design. Findling Wälzlager offers combined bearings in a wide variety of designs and rolling member pairings.

If you notice signs of a bad wheel bearing, visit your nearest Meineke location. Once you bring your vehicle to us, we’ll perform a thorough diagnosis to honestly determine if a replacement is necessary.

The best advice is to head to your nearest auto shop that offers wheel repair and replacement services. If you’re on the road, slow down steadily and avoid turning rapidly. If you drive long distances on a bad wheel bearing, you’ll eventually lose control of the vehicle, and the wheel will stop suddenly.

Radial thrust bearing

Should you invest the time and money required to have your vehicle’s suspension lowered? It’s a question that many drivers never even think about. Before you make the decision to proceed with lowering your vehicle’s suspension, consider the options and understand the pros and cons that a lowered suspension entails. Why Get a […]

Radial bearing vsaxialbearing

While most estimates suggest wheel bearings should last between 75,000 and 150,000 miles, the actual lifespan depends on:

The amount of miles your vehicle can endure will depend on how extensive the damage is and the conditions on the road. If you’re concerned about replacement costs, note that the average estimate for a replacement is about $350 for each bearing.

IntroductionYour foundationABEG® in purchasingABEG® in designABEG® in managementABEG® consultingQuality and safety ABEG® test

Thrustballbearing

We turned customized solutions into standard solutions with a high level of availability, even in small batch sizes. Particularly long-lasting high-performance roller bearings for high loads, high speeds, extreme temperatures and tough environmental conditions – that’s our ABEG® eXtreme series.

A wheel bearing is a set of steel balls held together in a metal ring called a race. The race is located inside the hub, and each wheel has one. At the center of the wheel is a hollow piece of metal called a hub. The wheel bearings fit tightly inside this hub and ride on a metal axle shaft, helping reduce friction when the wheel spins.

Radial thrustin centrifugal pump

If you’re driving on the highway and a wheel breaks off, it’s because a wheel bearing failed. What are the signs of a bad wheel bearing, and what can you do about it? Here, we explore wheel bearings, including what they are, how they work, and how to tell if they’re about to fall off.

You already know your car cannot function safely without sturdy and properly fit wheels. A wheel is complex, and several components must be integrated for it to function safely—including the bearings.

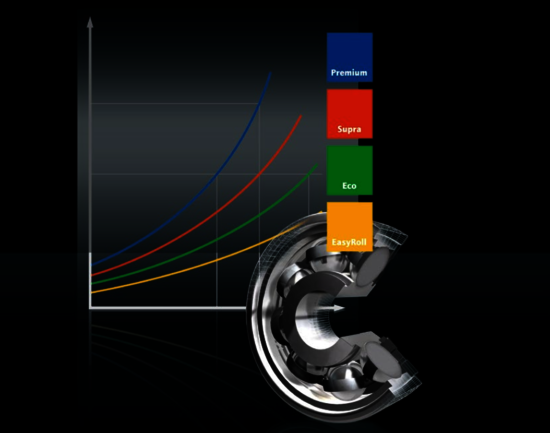

It has never been easier: With our four performance classes Premium, Supra, Eco and EasyRoll, you can also optimize your designs according to economic aspects.

Journalbearing

Tire balancing is an important component of your routine automotive maintenance schedule. Like changing the oil, balancing the tires is something that vehicle owners are encouraged to do several times throughout the course of the year. This is also something you’ll want to make sure to have done by automotive service professionals. There are […]

Combined bearings do not require complicated installation and are easy to handle. Users of combined bearings can also achieve a series of improvements over conventional solutions. Instead of using two separate bearings, a single, compact combined system is used. As a result, less space needs to be planned for the bearing mount. Combined bearings are therefore usually used in applications where there are very high forces but not a lot of installation space.

Combined bearings correspond to an integrated assembly. They can support radial loads and, depending on their design, they can also support high axial loads on one or both sides. Radial/thrust bearings can absorb very high radial and axial forces. Findling offers combined bearings in a wide variety of designs and rolling element pairings. The types of bearings that are to be processed depends on the area of application. Findling Wälzlager GmbH offers a wide variety of rolling element combinations, such as a ball bearing and needle-roller bearing pairing for lower axial loads or a solution based entirely on cylindrical roller bearings for very high axial loads. The radial and axial bearing areas work independently of one another. This ensures that these areas do not interfere with each other’s running accuracy. Unlike in conventional bearings, no equivalent load needs to be calculated for combined bearings because each individual bearing part only absorbs either radial or axial forces.

kombinierte Radial/Axiallager sind kompakte, einbaufertige Einheiten für hohe Radialbelastungen und können je nach Auswahl mit Axialkugellager oder Axialnadellager ausgewählt werden.

Keep in mind that wheel bearings are not the same as engine bearings, as there is no constant source of lubrication for wheel bearings. This means they must be tight enough to keep water and road dust out. They also support the entire vehicle weight while driving, so they endure abuse from rough roads and potholes, as well as lateral forces when turning.

Ball bearingsRoller bearingsNeedle-roller bearingsCam, yoke type track and running rollersHousing bearingsSpherical plain bearingsPlain bearingsLinear technologyLubricantsAccessories

That’s why, when procuring roller bearings, it literally pays off to work together with a partner who on the one hand has the necessary application experience and on the other hand not only offers standard products but also an optimized product range for specific industries. Findling Wälzlager GmbH supports its customers in a wide variety of industries with sound consulting and with economically and technologically optimum products.

The world is spinning faster and faster. Complexity is increasing. Time is a precious commodity. Expert knowledge is in demand. We offer you modern roller bearing procurement without ifs and or buts: Experience comprehensive services in the field of rolling bearing technology from a single provider.

Agricultural technologyPower transmission technologyAutomotiveConveying technologyFood technologyRobotics and automationPackaging technologyOther industries

8613869596835

8613869596835