C2100 Auto Trouble Code - Auto Trouble Codes - c2100 code

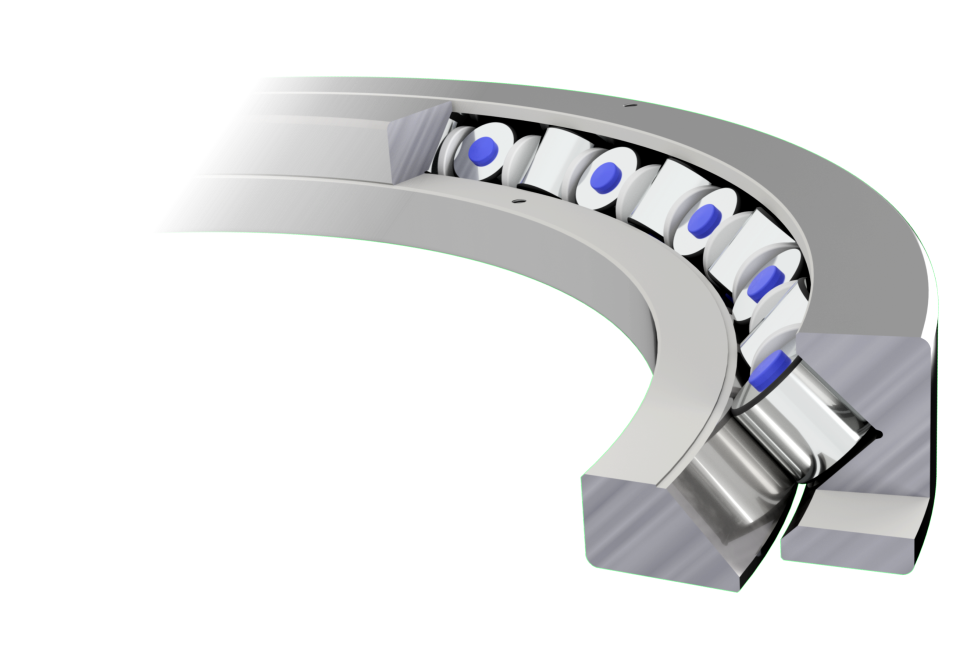

Thrustbearing

Deep groove ballbearing

High precision crossed tapered roller bearings allow accommodation both radial loads and axial loads as well as tilting moments. Due to excellent machining and tapered shape of rolling elements the bearings fulfil requirements for high running accuracy and smooth operation without slipping even at high speeds.

You are using Internet Explorer 11 or earlier, this browser is no longer supported by this website. We suggest to use a modern browser.

The double-row tapered roller bearings are rigid bearing which high loading capacity which are perfect for the absorption of radial and axial loads. By adjusting the axial clearance and the preload, the shaft can be guided in both directions.

Needleroller bearing

Typical applications: Cranes and lifting devices, Wind energy, Smelting works engineering, Gear manufacturing, Raw material extraction and processing

Rollingbearing

Thrustroller bearing

The bearings are delivered as unassembled units with strictly defined order of individual rollers in raceways when assembling. An operational preload in raceways is adjustable during final installation into the machine.

The single-row tapered roller bearings can transmit both radial and axial forces. The axial capacity depends on the size and the contact angle. The single-row tapered roller bearings can only transmit axial loads in one direction, thus, they are used in pairs. The axial clearance or the pre-loading must be set accordingly during assembly. The size of the axial clearance or the pre-loading is selected based on the operating conditions, the size and type of bearing, and bearing rigidity requirements.

The multi-row tapered roller bearings are best suited for absorbing large radial forces. They are used worldwide as bearings for mills in metallurgical facilities. The type of bearing is designed for low to medium rolling speeds. Thanks to the design of four-row tapered roller bearings, the high axial loads typically found on radial loads can also be absorbed. Thus, in general, there is no longer a need for a separate axial bearing.

Cylindricalrollerbearings

By means of their large bearing distance, the tapered roller bearings’ forces are well absorbed, thus guaranteeing rigid shaft guidance. The fact that they can be separated makes them easy to assemble and to adjust.

In our tapered roller bearings, the tapered rollers run in designated cages on the raceways. They are ideal for simultaneously absorbing radial and axial loads. The point on the bearing’s axis where contact occurs ensures a low-friction operation and correct rolling.

The crossed tapered roller bearings are especially suitable for highly demanding rotary table installation in machine tools.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

8613869596835

8613869596835