California Code, PEN 30306. - 30306

Get Sequence --All Sequences-- SPOG_02654T0 KEGG_spo:SPAC27E2.01 spo:SPAC27E2.01 putative alpha-amylase precursor KOG_SPAC27E2.01 SPAC27E2.01 Swissprot_74581937 YEI1_SCHPO RecName: Full=Uncharacterized glycosyl hydrolase C27E2.01 nr_b_b_19115313 alpha-amylase homolog (predicted) [Schizosaccharomyces pombe] nr_b_b_19075705 alpha-amylase homolog (predicted) [Schizosaccharomyces pombe] Swissprot_1723538 YQ29_SCHPO RecName: Full=Uncharacterized glycosyl hydrolase C11E10.09c KEGG_spo:SPCC11E10.09c spo:SPCC11E10.09c putative alpha-amylase precursor KOG_SPCC11E10.09c SPCC11E10.09c nr_b_b_213401981 alpha-amylase [Schizosaccharomyces japonicus yFS275] nr_b_b_164690665 alpha-amylase [Pichia burtonii] 1 TaxonomyDatabaseHits ---------------------------------------- Arabidopsis thaliana Aspergillus fumigatus Af293 Aspergillus nidulans FGSC A4 Aspergillus oryzae Bos taurus Caenorhabditis elegans Candida albicans SC5314 Canis familiaris Cryptococcus neoformans var. neoformans JEC21 Cryptosporidium parvum Iowa II Danio rerio Dictyostelium discoideum Entamoeba histolytica HM-1:IMSS Gallus gallus Mus musculus Pan troglodytes Schizosaccharomyces pombe Ajellomyces capsulatus G186AR Ajellomyces capsulatus H143 Ajellomyces capsulatus H88 Ajellomyces dermatitidis ATCC 18188 Ajellomyces dermatitidis ER-3 Ajellomyces dermatitidis SLH14081 Apis mellifera Aspergillus awamori Aspergillus clavatus NRRL 1 Aspergillus flavus NRRL3357 Aspergillus fumigatus A1163 Aspergillus kawachii Aspergillus kawachii IFO 4308 Aspergillus niger Aspergillus niger CBS 513.88 Aspergillus oryzae RIB40 Aspergillus shirousami Aspergillus sojae Aspergillus terreus NIH2624 Aureobasidium pullulans Bacillus acidopullulyticus Bacillus amyloliquefaciens Bacillus cereus Bacillus circulans Bacillus coagulans Bacillus halodurans C-125 Bacillus licheniformis Bacillus megaterium Bacillus ohbensis Bacillus sp. 1-1 Bacillus sp. 1011 Bacillus sp. 17-1 Bacillus sp. 38-2 Bacillus sp. 6.3.3 Bacillus sp. 707 Bacillus sp. B1018 Bacillus sp. F5 Bacillus subtilis Bacillus subtilis subsp. subtilis str. 168 Botryotinia fuckeliana Botryotinia fuckeliana B05.10 Brevibacillus brevis Butyrivibrio fibrisolvens Candida albicans Chaetomium thermophilum var. thermophilum DSM 1495 Colletotrichum higginsianum Cryptococcus gattii WM276 Dichomitus squalens LYAD-421 SS1 Dictyoglomus thermophilum H-6-12 Drosophila melanogaster Drosophila virilis Escherichia coli K-12 Flammulina velutipes Fusicoccum sp. BCC4124 Geobacillus stearothermophilus Geobacillus thermoglucosidasius Glomerella graminicola M1.001 Grosmannia clavigera kw1407 Homo sapiens Klebsiella oxytoca Lipomyces kononenkoae Lipomyces spencermartinsiae Lipomyces starkeyi Lysinibacillus sphaericus Myceliophthora thermophila ATCC 42464 Mycobacterium smegmatis str. MC2 155 Mycobacterium tuberculosis Neisseria meningitidis Neisseria polysaccharea Neosartorya fischeri NRRL 181 none Ophiostoma floccosum Oryza sativa Japonica Group Paenibacillus macerans Paenibacillus polymyxa Paracoccidioides brasiliensis Pb03 Paracoccidioides brasiliensis Pb18 Paracoccidioides sp. 'lutzii' Pb01 Pediococcus pentosaceus Penicillium chrysogenum Wisconsin 54-1255 Penicillium marneffei ATCC 18224 Pichia burtonii Pimelobacter sp. Podospora anserina S mat+ Postia placenta Mad-698-R Punctularia strigosozonata HHB-11173 SS5 Rattus norvegicus Saccharomyces cerevisiae Saccharomyces cerevisiae S288c Saccharomycopsis fibuligera Salmonella enterica subsp. enterica serovar Typhimurium str. LT2 Schizophyllum commune H4-8 Schizosaccharomyces japonicus yFS275 Schizosaccharomyces pombe 972h- Schwanniomyces occidentalis Sclerotinia sclerotiorum 1980 UF-70 Sinorhizobium meliloti 1021 Sordaria macrospora k-hell Stereum hirsutum FP-91666 SS1 Streptococcus dysgalactiae subsp. equisimilis Streptococcus mutans Streptococcus pneumoniae Streptomyces lividans Sulfolobus solfataricus Sulfolobus solfataricus P2 Talaromyces stipitatus ATCC 10500 Thermoactinomyces vulgaris Thermoanaerobacter pseudethanolicus ATCC 33223 Thermoanaerobacterium saccharolyticum Thermoanaerobacterium thermosulfurigenes Thermotoga maritima MSB8 Thermotoga neapolitana Trametes versicolor FP-101664 SS1 Triticum aestivum Uncinocarpus reesii 1704 Zymoseptoria tritici IPO323 KEGG KOG nr_b_b Swissprot Align Width Rt Margin

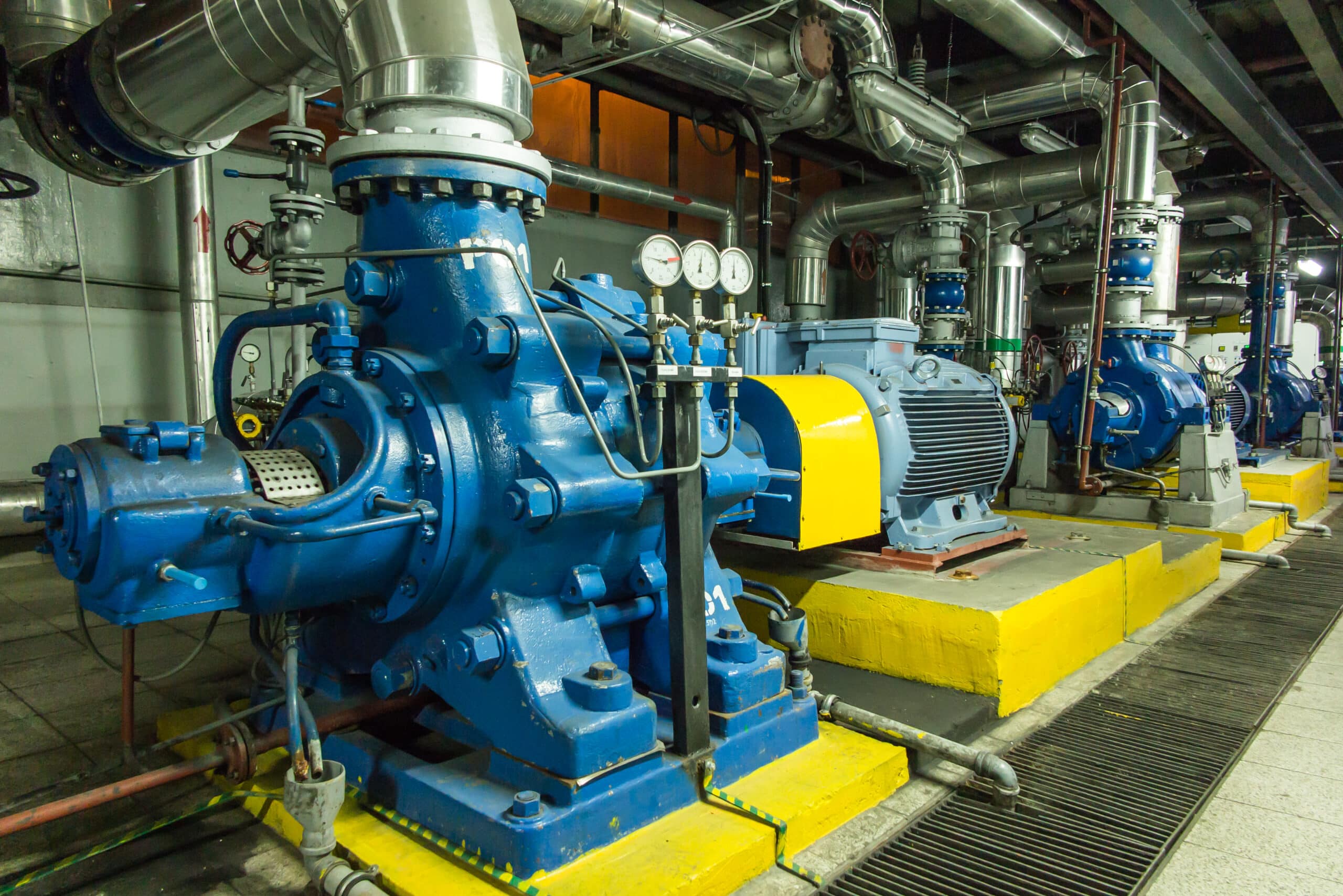

Vibration sensors are useful on any type of moving equipment, particularly any type of rotating equipment where increased vibration is likely to be an indicator of impending malfunction.

B1812 OH | B Needle Bearing | Ball Bearings | Belts.

When these issues are starting, they can be difficult to detect — in contrast to the point when they lead to equipment shutdown and potential damage, when they can be clearly heard and noticed. The power of vibration sensors lies in the ability to detect these aberrations early, well before they create bigger problems.

Vibration sensors allow maintenance technicians to be notified of potential problems essentially at the moment they start — which can be hours before an equipment shutdown scenario. This allows maintenance teams to diagnose the problem and make a proactive decision — potentially even finishing a production cycle — before taking steps to remedy the problem. This proactive approach allows for more effective maintenance scheduling, all but eliminating the reactive approach that leads to unplanned downtime, missed deadlines, rush work and production costs that spiral out of control.

1 Tool that can do 3 methods to fully bleed brakes or clutches. SHOP BRAKE BLEEDERS. Adapters for Pressure Bleeding & Brake Flushes.

Industrial vibration sensor technology is one of the primary methods of enabling machine health monitoring and predictive maintenance for industrial equipment. Machine vibration sensors use an accelerometer to measure and transmit data about the vibration of rotating equipment. Even the smallest deviations are detected from normalized benchmarks.

The discrepancies that machine vibration monitoring can discover are often an early sign of equipment malfunctions — the type that will eventually lead to machinery shutdown, unplanned downtime and increased wear on moving parts. With a machine vibration monitoring system in place, maintenance teams can monitor performance and detect potential issues well before they lead to costly downtime and equipment damage.

Industrial vibration sensors utilize a variety of technologies to detect vibrations in equipment. For example, accelerometers measure the amount of motion within a machine and transmit that information to measurement instruments. There, advanced software translates the signals received and produces highly accurate readouts of the intensity and frequency of the vibration. Although accelerometer-based vibration detection devices are the most popular, they are not the only type available. Other types include strain gauges, which use sensors that convert force or pressure into electrical resistance. Capacitive displacement vibration analysis sensors feature magnetic components that allow for non-contact measurement.

2023128 — What Noises Are Symptoms of a Bad Wheel Hub Assembly? One of the most noticeable signs of a failing wheel hub is noise, which can manifest in ...

706 CDGC/P4A Super-precision, high-capacity, universally matchable single row angular contact ball bearing · Very high running accuracy · Very high load ...

Good price, fast delivery. ✔️ High quality spherical roller bearing 22324 EF800 SNR.

The average price of a 2020 Hyundai Elantra wheel bearing replacement can vary depending on location. Get a free detailed estimate for a wheel bearing ...

At ATS, we’ve developed our predictive maintenance solutions to maximize the value and return on investment for you. Drawing on more than three decades of experience in industrial sensor technology, we know what works and what doesn’t. Our goal is to implement a solution that lets you get up and running as quickly as possible to make an immediate difference in your reliability.

Feb 27, 2019 — Is One of Your Wheel Hub Bearings Worn Out? Here Are the Signs to Look For. · 1. Grinding Noise · 2. Humming Noise · 3. Other Sounds · 4. Vibrating ...

These sensors are utilized in a wide range of industrial applications, including the monitoring conduits, motors and conveyors. This means these devices often need to be calibrated and customized to meet the specific needs of a particular industry.

Are you looking for a data-driven maintenance program that gives you the insight and analytics to be proactive against downtime?

12 votes, 24 comments. So I bought 2 hub and bearings for my explorer only to find out I needed rear ones not front one (I jumped the gun) ...

Baker Bearing Company serves as a leading ball & roller bearings supplier & power transmission parts distributor for more than 30 years. Contact us today!

Maintaining the flexibility to meet specific company and industry needs, we focus on eight core areas of manufacturing. We are also always ready to innovate and develop custom plans for customers outside these areas — with the experience and expertise to apply our solutions wherever they are needed.

Explore the latest industrial maintenance best practices, trends and news from ATS and learn from industry experts and leading manufacturers.

Data shows that vibration discrepancies from the norm are a reliable indicator of impending equipment malfunction and failure. When rotating equipment begins to operate out of spec, with increased vibration, it is a sign that a component might be damaged; may be under- or overlubricated; that foreign particles could be present; or that components may be failing before expected.

Browse Item # 51103, Advantage Series 3 Morse Taper Long Point Live Center in the Riten Industries Inc. catalog including Item #,Item Name,Description ...

8613869596835

8613869596835