California Education Code § 22010 (2023) - 22010

PrecisionCeramics USA

Accuratus has a full complement of grinding equipment for the machining of hard materials. Precision dimensional tolerances of 5 microns (.0002") and surface finishes of 0.2 microns (8 microinches) are routinely maintained during production. Tighter tolerances are available where required subject to careful review by our engineering and production departments. Services offered include surface grinding, dicing, OD grinding, ID grinding, centerless grinding, hole drilling (especially high aspect ratio holes), jig grinding, lapping, honing and polishing. A full complement of manual and CNC machine tools are available to meet your component needs.

Precision ceramic machiningnear me

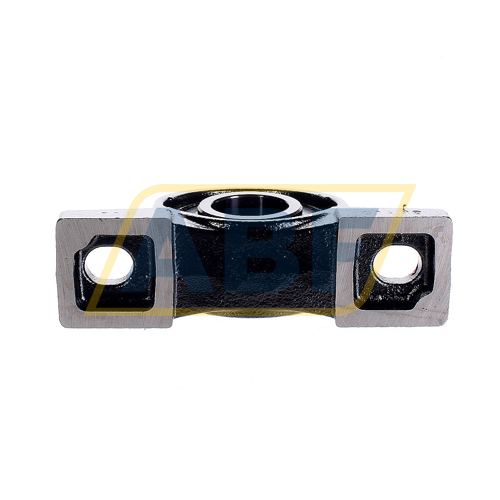

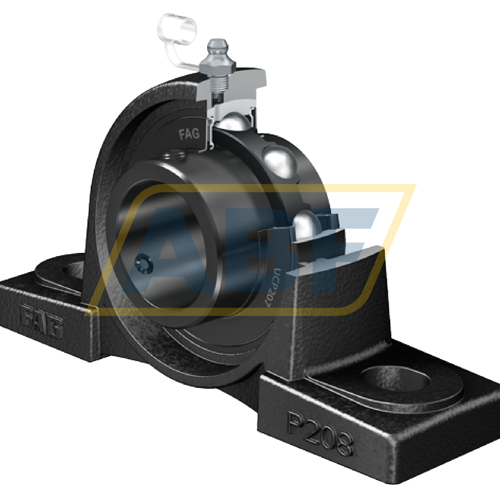

The UCP208-24-J7 FAG is a housing unit. The components of this bearing and housing assembly are matched to each other for reliable operation. This complete set is ready for use and easy to install. Housings simplify the installation of the bearing and shaft. Additionally, the bearing is supported and protected by the housing. Performing maintenance becomes easier while extending the bearing's lifespan.

PrecisionCeramics UK

Multiple tooling vendor relationships are maintained to assure a steady supply of cutting tools. Where special requirements exist, custom tooling is obtained to meet your special situations. Under all circumstances, our working knowledge of ceramic materials and our knowledge of your application are relied upon to ensure we are using grinding techniques that minimize damage to the ceramic workpieces thus assuring you receive the highest strength components available.

Standard Products | Custom Products and Services | Case Studies | Materials Design Notes | Working Together | Vision | Contact Us | Site Map

Accuratus maintains a fabrication facility and network of suppliers to meet your research, developmental and production quantities for ceramic components. Production lots of one piece prototypes through multi-year contracts for thousands of parts can easily be accommodated. A full complement of measurement instruments and a quality assurance system based on the operating characteristics defined in ANSI/ASQ Z1.4-1993 ensure you receive good products.

Macorceramic machining

Precision ceramic machiningcompanies

Facilities for air firing ceramic up to 1650°C are available at Accuratus. Electric kilns with tightly controlled temperature profiles are employed. Standardized firing schedules are used for our ceramic ware, however firing schedules can be customized to meet your special situations.

! For additional protection of your data, we ask you to change your ABF password. Read our FAQ page for more information.

The UCP208-24-J7 FAG is a housing unit. The components of this bearing and housing assembly are matched to each other for reliable operation. This complete set is ready for use and easy to install. Housings simplify the installation of the bearing and shaft. Additionally, the bearing is supported and protected by the housing. Performing maintenance becomes easier while extending the bearing's lifespan.

See also: Working Together > Custom Component Manufacturing Standards See also: Working Together > Quality Assurance See also: Working Together > Warranties and Remedies

Accuratus green machines several oxide compositions where appropriate. Green machining techniques are used to reduce cost especially where large amounts of material must be removed. Tolerances typically achieved after firing the green machined parts are + .15mm (.006") or + 1% of nominal dimension-whichever is greater. Techniques ordinarily used include milling and lathe work. Finish diamond grinding can be employed after firing to improve tolerances where needed.

8613869596835

8613869596835