Cam Bearing failure signs? - bad cam bearing symptoms

Radial loadvs axialload

Of the four types of bearings listed in Table 1, radial ball bearings and radial roller bearings are used most often. We will explain a bit about those two types of bearings.

Bearings support forces applied from various directions, and so they can be categorized based on the "direction of the force". Firstly, we will explain about the forces applied to bearings.

How to calculateradial loadonbearing

These use barrel-shaped convex rollers as their rolling elements. As shown in Figure 7, they are inserted between a spherical outer ring raceway surface and an inner ring raceway surface. This is why the inner ring, rolling elements and cage in a spherical roller bearing are able to rotate while inclined toward the outer ring.

The force applied to a bearing is called the "load". The force applied perpendicularly to the shaft is called the "radial load", and that applied in the same direction as the shaft is called the "axial load".

Radial loadexample

In this way, bearings at all times have forces applied from various directions. The bearings are categorized based on which direction the force is coming from and how much force can be applied.

Axialload bearing

Radial roller bearings are roller bearings that can support a force perpendicular to the shaft. They can support an even greater load than radial ball bearings, and there are bearing types that are made to suit the type of roller.

There are various types of bearings, and we must select the type of bearing most suited to a particular machine's structure and use.

The contact angle is the angle formed by the direction of the load applied to the bearing rings (races) and rolling elements, and a plain perpendicular to the shaft, when a "radial load" and "axial load" are both applied to a bearing.

Bearingaxialloadcalculation

Radial loadformula

As shown in Figure 8, spherical roller bearings can support a large load, and are used in machines where the shaft is easily bent.

In this part, we will divide the types of bearings into broad categories, and then explain the main features of bearings.

Bearing loadcalculation

Angular contact ball bearings can support a radial load and a one-directional axial load at the same time. When axial loads coming from both directions are to be supported, two or more angular contact ball bearings are combined together.

Figure 1 shows the forces applied to the bearing used in a car's wheel with a tire on it. The force generated by the weight of the vehicle (the blue arrow in Figure 1) is applied perpendicular to the axle. Conversely, the centrifugal force generated when the car turns(the red arrow in Figure 1) is applied in the same direction as the axle.

Deep groove ball bearings are the most widely used among all bearings. They can support both a radial load and a certain amount of axial load coming from both directions at the same time. If a bearing to support a very large axial load is needed, the "angular contact ball bearings" explained below are used.

There are various types of bearings categorized by the direction and magnitude of the force they can support, and the optimal bearing type is selected, taking the machine's structure into consideration.There are many other types of bearings we didn't introduce in this article. For those who wish to learn more, please click on the Koyo Bearing product-type pages or the catalog below. You can also contact JTEKT directly.

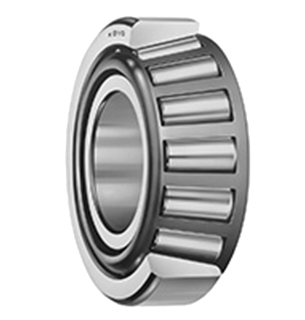

These use tapered rollers in the shape of tapered trapezoids as their rolling elements. Tapered roller bearings are the most widely used among all roller bearings, and can support a radial load and a one-directional axial load at the same time. When axial loads coming from both directions are to be supported, two or more tapered roller bearings are combined together.

Radialand axialloadonbearing

As can be seen in Table 1, bearings can be categorized into four groups based on the direction of the force supported and the shape of the rolling elements. For more details, please take a look back at Part 3!

These use needle rollers as their rolling elements. Needle rollers have a smaller diameter than cylindrical rollers, and so (as can be seen in Figure 5) the bearings have a smaller cross-sectional height and contributed to the down-sizing of machinery.

These use cylindrical rollers as their rolling elements. Cylindrical roller bearings can support an even greater radial load than deep groove ball bearings, and are used in machinery where they will experience strong impacts.

8613869596835

8613869596835