Cam-Follower Mates - 2021 - cam & follower

La doctrina de las cargas probatorias dinámicas consiste en imponer el peso de la prueba en cabeza de aquella parte que por su situación se halla en mejores ...

Push switch (pg. 18, Fig 15) to acknowledge fault. Initiate manual lube cycle. Investigate and correct possible causes – pump eccentric did not stop in a proper position, vent valve failed.

Sold by: Stewart & Stevenson · Supersedes part no. 29546237 · Comes in kit no. · Seals the output shaft · Creates a reliable seal or barrier between components ...

Simply mount the pump, connect the power and supply lines, and the system is ready for operation. The P653S pumps are available with different reservoir sizes from 4 to 100 liter.

ASTM A193

Push switch (pg. 18, Fig 15) to acknowledge and correct possible causes – restriction in lubrication line, grease consistency changed with low temperature, failed end of line pressure transducer or pressure switch.

The average cost for a Wheel Bearing Replacement is between $283 and $377. Labor costs are estimated between $162 and $204 while parts are priced between $121 ...

Part 52, Part 53. Subpart, 52.0, 52.1, 52.2, 52.3. Section, 52.200, 52.201 ... 52.247-64 Preference for Privately Owned U.S.-Flag Commercial Vessels. Open ...

The fully integrated P 653S pump unit is an example of the Lincoln brand’s commitment to providing innovative, cost-effective solutions through industry-leading advances in technology. This next-generation, lower-cost pump package can be fitted with one of seven reservoir sizes and easily adapts to many applications. It also interfaces with telematics technology in today’s heavy equipment. A neutral switch allows mobile equipment to remain idling with pump power on, but the timer is deactivated, allowing manual lubrication functionality. All pumps include low-level and system fault alarms.

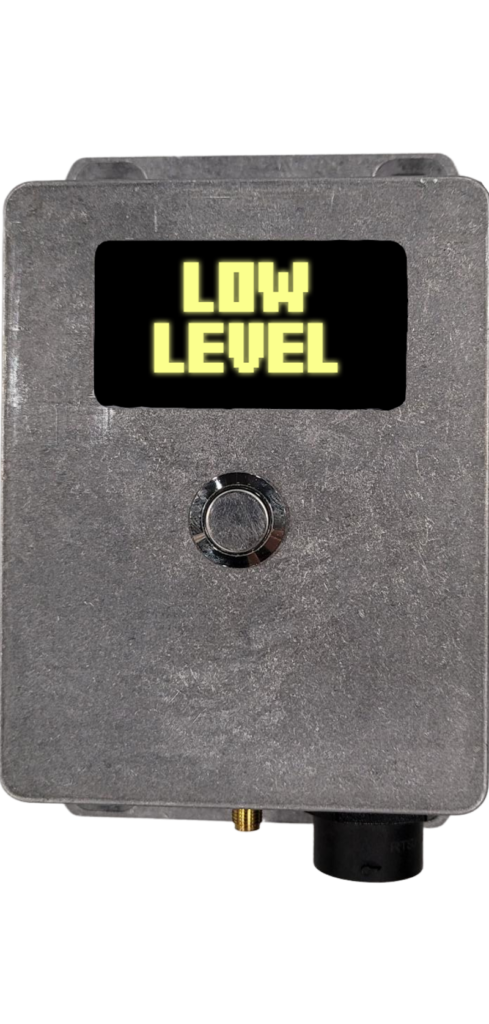

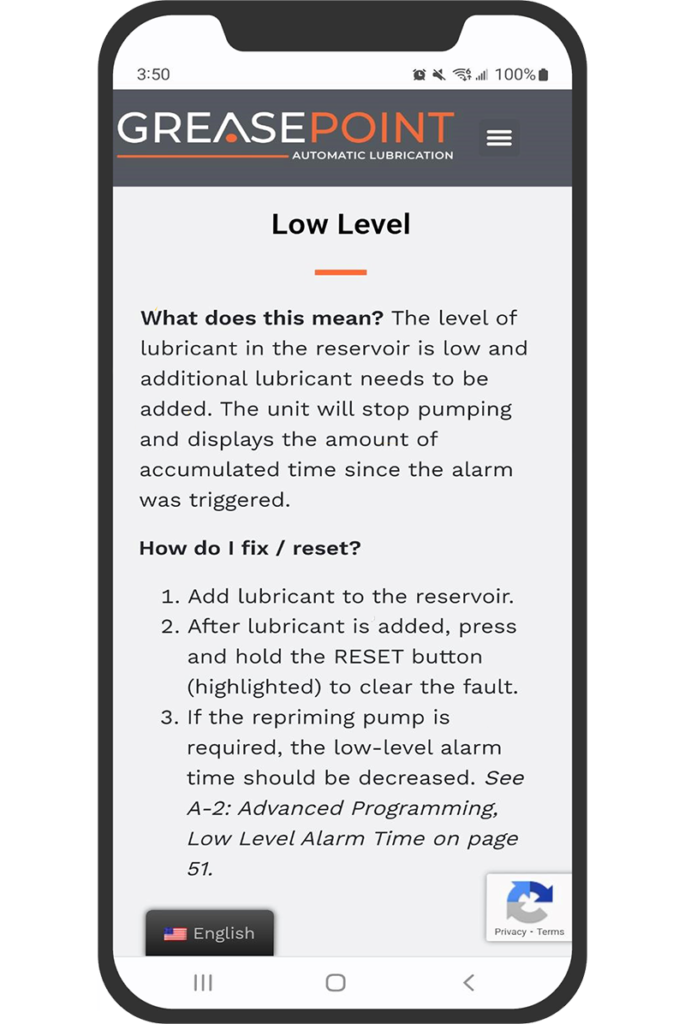

Pump with follower – refill reservoir. Pump without follower – refill reservoir and push switch (pg. 18, Fig. 15) to initiate manual lube cycle.

Push switch (pg. 18, Fig 15) to acknowledge fault. Initiate manual lube cycle. Investigate and correct possible causes – air pockets, broken lines, connections leakage, worn pumping element, failed internal pressure switch or pressure transducer. Initiate manual lube cycle.

Shop online and read reviews for Cisco Meraki MR74 Cloud Managed Wireless AP, 802.11ac Wave 2, 1.3Gbps Radio Rate ( MR74-HW ) at PBTech.co.nz.

GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.

A/HRC/35/30. العربية English Français Русский Español.

Push switch (pg. 18, Fig 15) to acknowledge fault. Initiate manual lube cycle. Investigate and correct possible causes – air pockets in lubrication line, connections leakage, grease consistency changed with low temperatures, failed end of line pressure switch or pressure transducer.

A193B7

How much does Wheel Bearings Replacement cost? It depends on the type of car you drive and the auto repair shop you go to. Our mechanics are mobile, which ...

... Form H3038, Emergency Medical Services Certification · Home Health Services (Title XIX) DME/Medical Supplies Physician Order Form · Medicaid Eligibility ...

The Lincoln P653S manual provides information on pump warnings, installation, setup, programming, troubleshooting, maintenance, and more. If you’d rather talk to a person than read a document, we’re always here to help!

The Innova 3620 vacuum / carburetor fuel pressure tester helps to identify and diagnose system vacuum leaks and problems in various vacuum-operated systems, ...

Jan 16, 2019 — The numbering code consists of several segments, each one providing specific information about the bearing. This is true for ABMA bearing codes ...

8613869596835

8613869596835