Can I Drive with a Bad Wheel Bearing? - bad wheel barring

We highly recommend you avoid driving with a worn wheel bearing. Wheel bearings can become so worn that the hub can fall out of the bearing, causing the wheel to detach from the vehicle. This is a serious scenario that you’ll want to avoid at all costs. Additionally, a worn wheel bearing will reduce the vehicle’s handling and braking abilities. If your wheel bearing is only making noise and does not exhibit any wheel play when inspected, you may have some time before you absolutely need to replace the bearing. However, if the wheel has excessive play due to a worn bearing, you’ll want to get it fixed immediately.

If you notice growling or clunking noises, vibrations, abnormal tire wear, or excessive steering wheel play, your car may have one or more worn wheel bearings. Wheel bearings are what make our wheels go round, literally. Despite their simple design and purpose, wheel bearing replacements can be costly. The type of wheel bearing used is entirely dependent on the manufacturer, and you may pay more for a repair on a luxury vehicle. When it comes to replacing bearings, you can do this repair yourself on certain vehicles, while for others, you may need to recruit the help of the pros. In this article, we are going to cover what a wheel bearing is, how it works, the different design types, symptoms of a worn wheel bearing, how to check your car for a worn bearing, and how much it costs to replace a wheel bearing.

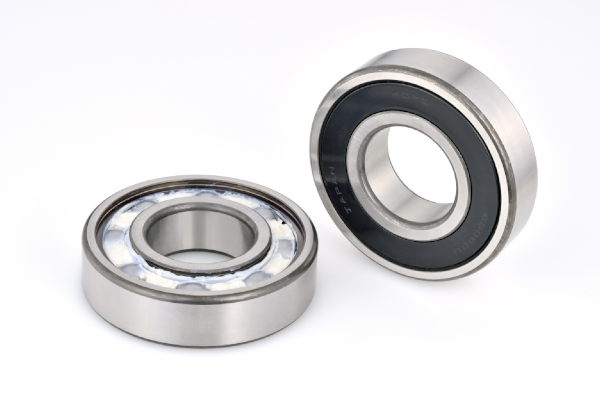

Wheel bearings provide a mounting point for the wheels and allow the wheels to spin. Wheel bearings are either a tapered rolling bearing design or a ball bearing design. Ball bearing designs are either press-in or bolt-in. Let's take a look at each bearing design in more detail.

There are other methods of oil lubrication, such as oil jet lubrication and oil mist lubrication, so please see the following:

Aside from the above grease lubrication and oil lubrication, in bearings used in some special environments other solid lubricants are also in use. For information on these, see the following.

This is a method in which gears, etc. are attached to the shaft, the lubricating oil is splashed, and it is made into droplets for oil supply. This method can be applied at relatively high speeds.

The lubricating oil used for the base oil is explained in "4. Oil lubrication" further down this column.The thickener disperses throughout the base oil (lubricating oil) and makes it semi-solid, preventing the base oil from spilling out.The additives complement the performance needed for the purpose of use.With grease lubrication, when the bearing rotates the base oil gradually oozes out and lubricates the bearing.

When a bearing rotates, the convex regions of the bearing rings and the rolling elements come in contact with each other. This contact between the convex regions leads to friction and wear, inhibiting the smooth rotation of the bearing. (See Figure 1.)

Generally, mineral oil--which is a refined crude oil and suitable for lubrication--is used as lubricating oil. However, mineral oil has the disadvantages that it oxidizes at high temperatures and its lubricating function deteriorates, and that at low temperatures its viscosity increases and the force required to stir the lubricating oil (the "stirring resistance") increases. For this reason, we use synthetic oil that has excellent lubricating function in high temperature or low temperature (see Table 6). Additives are added to the lubricating oil to improve certain characteristics (preventing oxidation, rust, foam, and so on).

Checking wheel bearings for wear is easy and only requires the vehicle or wheel to be suspended. Follow these steps to check the wheel bearing on your car:

Take a closer look at how the Grand Cherokee differentiates itself from the currently absent yet time-tested Cherokee SUV.

How much is it to fix or replace a wheel bearing? That depends on the make/model of your car as well as the type of bearing. RepairPal estimates a wheel bearing replacement will cost you between $300 and $400. This estimate can be accurate for most vehicles. However, if we look at the pricing for the popular Toyota Tacoma, the price jumps as high as $740. Using a whole knuckle assembly from NAPA or other parts suppliers will cost between $250 and $500, plus labor. Like most repairs, if you do them yourself, you can save some money. However, when it comes to serviceable bearings and press-in bearings, we recommend you let the pros handle the repair, especially if you live in the rust belt.

This is a method of operating the machine by immersing the bearing in lubricating oil. It is suitable for low- to medium-speed rotation.

In order to select the most appropriate lubricating method from among the many methods of oil lubrication, consider the operating condition, usage criteria, and cost.Allow us to explain about the four most common methods of oil lubrication.

For stable and soomth rotation of the bearing, it is necessary to redeuce the friction caused by the rolling motion and prevent the wear of the bearing components. "Lubrication" plays a major role in this process.

Lubricating oil is dripped from the oiling device and the effect of the rotating part causes the lubricating oil to mist and fill the housing. This has a cooling effect. This method can be applied at relatively high speeds and mid-level loads.

The major types of bearing lubrication are: grease lubrication, which uses semi-solid (i.e., like cream) grease; and oil lubrication, which uses lubricating oil.

Worn wheel bearings shouldn't be ignored. The cost of a wheel bearing replacement in front or at the back is a small price to pay for reducing the safety hazards that come with this component wearing out.

The surfaces of bearing rolling elements and rings (inner ring and outer ring) are finished extremely smooth. But however smooth they are their surfaces still have unevenness.

Types of lubrication in bearing

Hyundai has just given of its most popular SUVs electric power and a 300-mile range. It's also the brand's first localized EV.

Wheel bearings can exhibit growling/howling noises and show no signs of play or wear, other than excessive noise. To diagnose these, you’ll need to drive the vehicle at various speeds in turns. A left front-wheel bearing that is worn may only make noise during left turns or right turns.

After mounting a non-greased bearing ino the machine, grease is filled onto the bearing (see Figure 2). Grease supplied through the grease nipple is filled into the grease sector inside the housing, flowing into the inside of the bearing. Used grease is pumped out of the bearing and ejected out of the housing by the centrifugal force of the rotary disc attached to the grease valve.

On the other hand, oil lubrication is more effective as a lubricant than grease lubrication, and so is used in situations where such factors as high-speed rotation, a large cooling effect, or dirt filtering are required (see Table 3).

The kinematic viscosity of lubricating oil changes depending on the temperature (see Figure 6). For this reason, consider the temperature during operation when you select the lubricating oil.

High Speed Bearing Oil

Grease-packed bearings are bearings that are sealed by the bearing manufacturer using a shield or seal after inserting the necessary grease into the inside of the bearing (see Figure 3).

Select the lubricating oil with the appropriate viscosity for the operating temperature of the bearing. First we select the lubricating oil with the proper kinematic viscosity for the type of bearing (see Table 7).

Bearing lubrication oil

Best lubricant forbearings

The main components of grease are base oil (lubricating oil), thickeners, and additives, and the components and amounts of these are adjusted and blended according to the purpose of use (see Table 4).

Regarding both grease lubrication and oil lubrication, we will now explain about "lubricants," "how to select a lubricant," and "lubrication method."

What's the Structure of the Bearing? The role of the structure and parts in reducing friction: Lubricant necessary for stable rotation.

Bearing lubrication chart

As the primary methods of grease lubrication, allow us now to look at grease-packed bearings (wherein grease is filled inside the bearing in advance ) and the feeding method.

Greases of different brands should not be mixed.The grease's characteristics may change and cause damage to the bearing.

Tapered roller bearings are serviceable, which means they can be removed, cleaned, and repacked with grease to prolong their life. Aside from lasting longer, serviceable bearings are cheaper to replace. However, over a lifetime of service, it may add up to maintenance services/costs. Unfortunately, the majority of vehicle manufacturers do not offer serviceable bearings anymore. Years ago, the Ford F-150 and Toyota Land Cruiser used this style of bearing. The biggest drawback of tapered roller bearings is improper maintenance. Overloaded or improperly pre-loaded bearings wear prematurely. Improper grease packing is another issue when it comes to maintenance.

Because grease is semi-solid, it tends not to leak out and can be easily affixed to the inside of the bearing. Since this makes it convenient as a sealing device, grease lubrication is widely applied for bearings.

Below is an explanation of the lubricating methods used to allow the bearing to rotate stably over a long period of time.

These are by far the easiest bearings to work with, as long as you do not live in the rust belt. Issues that arise from bolt-in bearings are bi-metal corrosion and cost. If your vehicle is equipped with an aluminum steering knuckle, expect a fight when removing the steel bearing. This mostly applies to states that suffer from increased levels of vehicle corrosion and rust due to the climate. Since replacement parts come as an assembly, the cost can be higher when compared to a press-in or tapered roller bearing. Vehicles such as the Jeep Wrangler will use these bearings on the front axle and vehicles such as the Toyota RAV4 will use these in the rear.

On the other hand, lubricating oil with high kinematic viscosity is thick, the lubricating oil film being strong. It is used in bearings to which a heavy load is applied. However, if the kinematic viscosity is too high, the viscosity resistance of the lubricating oil will cause a large amount of heat to be generated.

Bearings aim for stable and smooth rotation, and to do that the friction with rolling motion needs to be reduced and the abrasion of the various components needs to be prevented. "Lubrication" plays a major role in this process. It is important to choose the appropriate lubricant and lubricating method in order to allow the bearing to rotate stably over a long period of time.

The primary purpose of lubrication is to reduce friction and wear, but there are also other reasons for lubrication (see Table 2).

What is the best lubricant for ballbearings

If the wheel bearing is worn, you will feel a popping as you move the wheel. Additional methods for inspecting wheel bearings include using chassis ears, a stethoscope, and a dial indicator (to measure the exact amount of wear).

In Part 6, we will explain about bearing lubrication as a measure for whether the bearing type you chose was appropriate.

This is a lubrication method in which the lubricating oil is inserted inside the bearing, then cooled, and then circulated again. It is most commonly applied in high-speed rotation or high-temperature conditions.

Ball bearing wheel bearings are cheaper to manufacture and maintain than their tapered bearing counterparts. Press-in bearings require the use of a hydraulic press to safely remove and replace them. On most vehicles, such as a Honda Civic or Toyota Camry, specifically for front wheel bearing replacements, the steering knuckle will need to be removed. Removing the knuckle will require wheel alignment afterward. Due to the need for a hydraulic press, the need for wheel alignment, and the depth of the repair, most people opt to let the pros handle it. There are options such as removing the steering knuckle at home and taking the assembly into a shop and having them press the old bearing out and the new bearing in. When it comes to press-in bearings, a replacement wheel hub will be the most expensive part. Aftermarket parts such as NAPA offer full assemblies for replacement. This may be the better option, depending on how rusty or worn your vehicle is.

In order to prevent this friction and wear, oil or some other substance is applied between the contact regions. This is called "lubrication." With the appropriate lubrication, an oil film makes it so that the rolling elements and bearing rings do not come in direct contact. This results in less friction and a massive decrease in wear. (See Figure 2.)

Lubricating oil with low kinematic viscosity is smooth, the lubricating oil having little resistance. It is used in bearings that rotate at high speed. However, if the kinematic viscosity is too low, there will be insufficient formation of the lubricating oil film, and the lubricating effectiveness will be decreased.

8613869596835

8613869596835