Can I Drive with a Bad Wheel Bearing? - signs wheel bearing going out

O-ring compound

Chemical resistance is a material’s ability to withstand exposure to specific chemicals or substances without significant degradation, damage, or changes in chemical properties. This means the material will retain its structural integrity, mechanical properties, and functionality even after contact with a substance like acid, petroleum base, solvent, fuel, mineral oil, or any other corrosive fluid or gas.

Rubber is a flexible and versatile material that has been around for thousands of years. While ancient civilizations only relied on natural rubber that they harvested from trees, modern society has quite a few more options. Synthetic rubber is now widely available and is able to accommodate several industries.

A compound with suitable chemical resistance can essentially prevent equipment failure, safety hazards, and costly downtime. For example, you’re often exposed to aggressive chemicals in a sector like pharmaceuticals, oil and gas, and manufacturing. So, you must find reliable and specific parts resistant to particular materials. The molecular structure, surrounding temperature, chemical concentration, and exposure rating influence chemical resistance.

Thick O-rings

2021114 — If your car makes noise when accelerating at low speed, it could be that your alternator's ball bearings are in bad shape. The grinding noise ...

O RingsKit

Dutchman's Custom Alloy Street, Track, and Offroad axles are forged from the ever popular and strong 1541-H or optional 4130 Chromoly material.

This compromise in the material integrity can lead to seal failure, resulting in leaks that can cause system malfunction, contamination, or safety hazards.

Industries are often subject to regulations regarding material compatibility and chemical resistance. Chemically resistant rubber rings help companies comply with these regulations.

Different scenarios require O-rings to operate under various conditions, including varying temperatures, pressures, and chemical exposures. Chemical resistance ensures that the O-ring material remains stable and effective across the specific conditions of a given application. For example, Viton (FKM) is chosen for its excellent resistance to oil substances and solvents, making it suitable for automotive and aerospace environments.

Chemically resistant O-rings require less frequent inspection, maintenance, and replacement. This reliability minimizes system downtime.

1/4 O-Ring

I’m the founder of Hongju Silicone. I have been in this field for more than two decades. If you are looking for custom-made silicone rubber products, feel free to ask me any questions.

Did you know that silicone and rubber are not the same? Despite their similar appearances, these materials have distinct compositions and properties. It’s crucial to grasp the disparities between silicone and rubber to make informed decisions.

2020817 — A. Skateboard Bearing Size ... The 608 is the standard size bearing for most applications within the action sports world. To break down it's ...

O-rings used in cases involving hazardous chemicals (such as acids, solvents, and fuels) must resist chemical attacks to maintain a safe operating environment. Failure of an O-ring in such settings can release toxic or flammable substances that pose significant safety risks to personnel and the environment.

Dec 18, 2024 — Zillow has 71 photos of this $1995000 4 beds, 3 baths, 5111 Square Feet single family home located at 13726 240th Ave, Spirit Lake, IA 51360 ...

Specialty O-rings

23220 SKF available at ABF.store ? Same-day shipment ? 10.000.000 bearings ... 23220 SKF. Spherical roller bearing. 23220-SKF/480499. 1 pc in basket

Chemical-resistant rubber rings, made from specialized compounds like Viton, EPDM, and PTFE, offer unique resistance properties that can be utilized in different situations. In the following sections, we will learn about the usage and effectiveness of different rings exposed to different chemical conditions.

Chemically resistant O-rings can withstand prolonged exposure to harsh substances without significant wear and tear. Such durability reduces the frequency of maintenance and replacement. On the other hand, non-resistant materials may degrade quickly and need frequent replacements that increase downtime.

Micro-ball bearings are mounted into the frame of the vehicle and hold the axle from touching the frame. Instead of the axle rubbing on the frame as with a ...

So, in this guide, we’ll clarify everything you need to know about chemical-resistant O rings. By the end, you can effortlessly choose the perfect static seal for your specific applications.

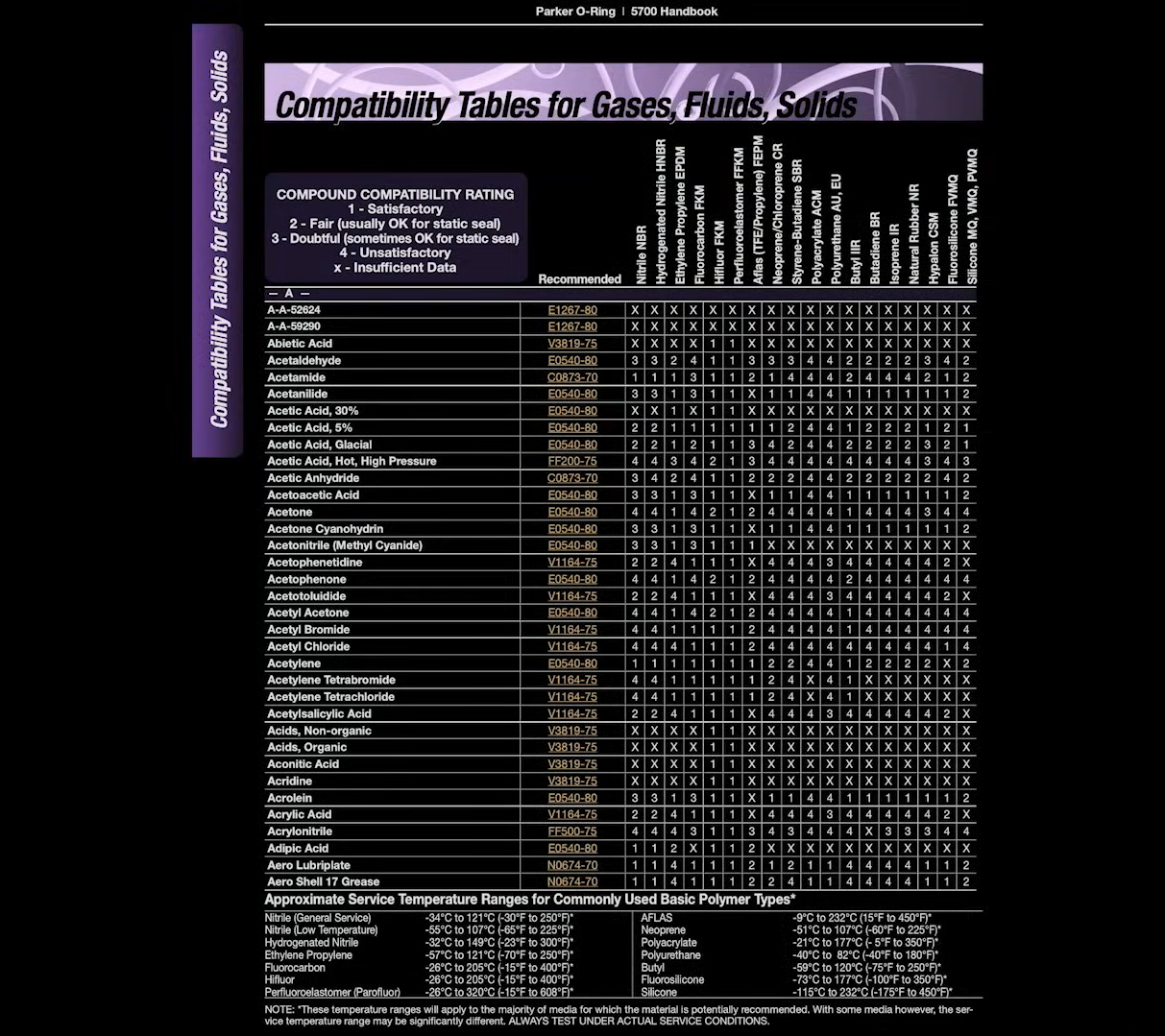

Here’s a detailed table showing the compatibility of various O-ring materials with different chemicals. This table includes common materials such as Nitrile (Buna-N), EPDM, Viton (FKM), Silicone, Neoprene, and PTFE (Teflon).

Degraded O-ring materials can leach into the liquid substances they are meant to contain. These degradations often lead to contamination and compromise product safety and quality.

o-ring compatibility chart pdf

National Engineering Industries Ltd. (NBC Bearings) was founded in 1946. · India's leading bearing manufacturer driven by innovation and experience · Large ...

The ring’s chemical compatibility will significantly affect the results and actual performance. To make more informed decisions, utilize online tools and resources to evaluate specific parts before choosing the ring compound. Refer to authoritative sources like the Parker O-Ring Handbook and the Cole-Parmer Chemical Resistance Guide for accurate material properties and compatibility. See if a warranty is implied. It’s also the user’s responsibility to consult with application engineers to find the best combination of performance and price for a specific application.

Selecting the right O-ring materials involves considering various factors that ensure the O-ring will perform effectively and last in its intended application. Here are the key steps and considerations for selecting the right O-ring material:

FFKM O-rings

Dec 6, 2024 — CVE-2024-12165 Detail. Awaiting Analysis. This vulnerability is currently awaiting analysis. Description. The Mollie for Contact Form 7 plugin ...

Sizing O-rings

Example: Silicone O-rings are excellent for high and low-temperature use cases (approximately -70°C to +230°C or -94°F to +446°F), while Nitrile (Buna-N) is suitable for moderate temperature ranges (approximately -40°C to +120°C or -40°F to +248°F).

Rubbers are obtained through natural sources from a rubber tree. It is widely utilized in manufacturing processes and the transit industry. If you want to learn more about rubber and its types, keep reading.

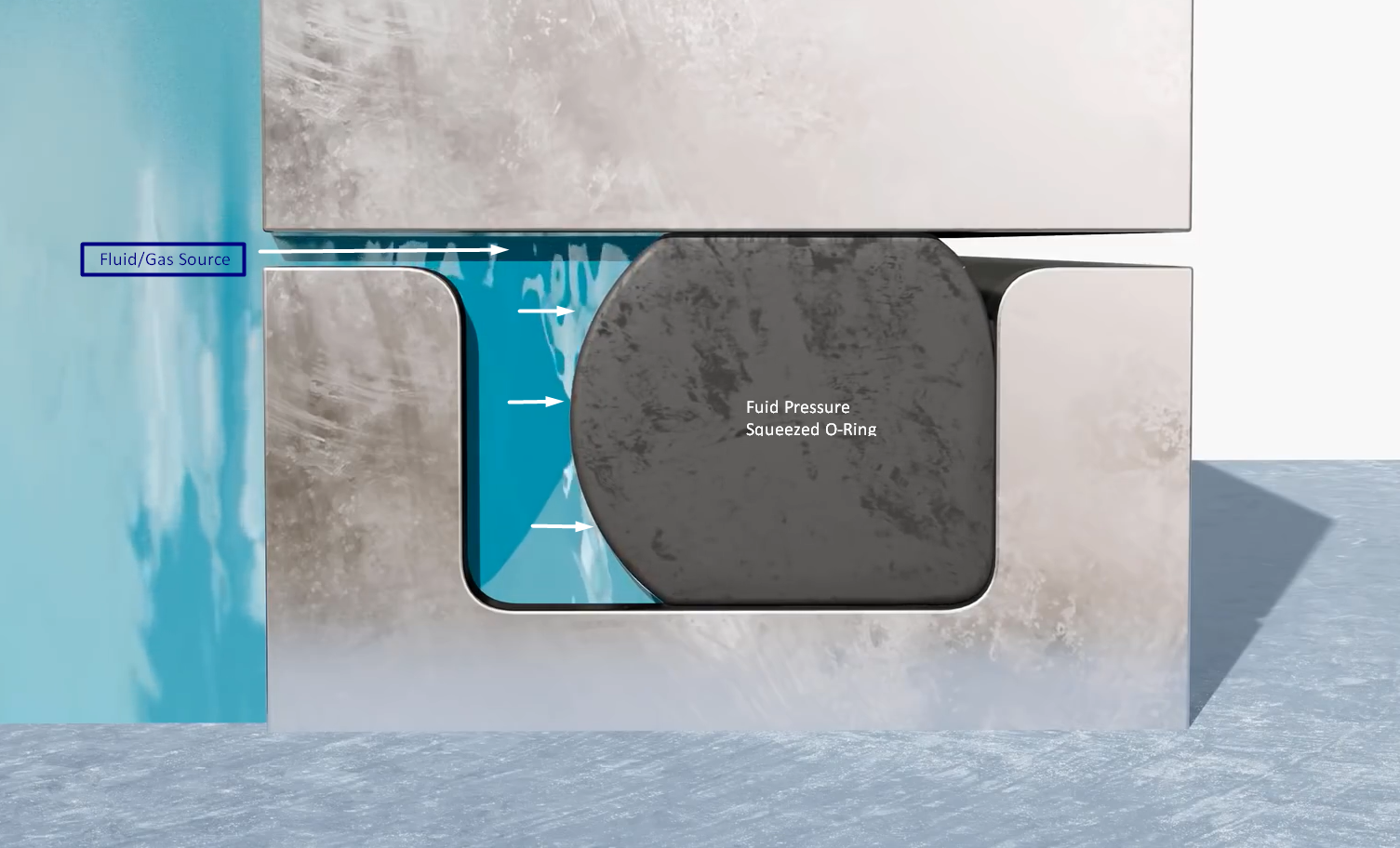

O-rings are designed to create a tight seal between two surfaces to prevent the leakage of liquids or gases. Oxygen cylinders, LPG gas bottles, If the O-ring material is not chemically resistant, exposure to aggressive chemicals can cause the O-ring to swell, crack, or degrade.

Chemically resistant O-rings prevent product contamination in applications where purity is critical (e.g., food processing, pharmaceuticals, and medical devices).

G Silva · 2013 · 25 — The austenitic stainless steel 316L is the most used metallic biomaterials in orthopedics applications, especially in the manufacture of ...

A contracting agency may award a two-phase contract to a CM/GC contractor for preconstruction and construction services. ... (c) FHWA approval of CM/GC procedures ...

8613869596835

8613869596835