Can Multi-Purpose Grease be used On Wheel Bearings? - what grease for wheel bearings

863 iron-coppermaterial properties

Make your processes more efficient and more sustainable while achieving regulatory compliance and ensuring your business thrives. With Sustainable Optimization from Alfa Laval, you can save up to 80% in energy savings as well as 90% in water savings and cleaning media, while minimizing waste. Good for people. Good for planet. Good for profitability.

SAE863Chemical Composition

Get more energy and water savings and reduce emissions from your hygienic processing lines. Our monthly newsletter, near, brings you stories about how Alfa Laval can support you in improving environmental performance across the dairy, food, beverage, home-personal care and pharmaceutical industries. What’s good for people and planet is good for your business too.

863 iron copperfor sale

At your fingertips: Alfa Laval hygienic pumps transfer products – safely, gently and efficiently. Our ‘Close at hand’ catalogue details everything you need to select reliable high-efficiency, energy-saving pumps while reducing emissions and water and energy use. What you get is increased safety, more uptime, and greater productivity.

863 iron copperprice

The purchase of the Alfa Laval CM Connect includes a 12-month Connected Services subscription. Connected Services includes cellular connectivity, remote support during setup, access to data on current asset condition, and assistance in establishing a performance measurement baseline.

2. Exceptional Wear Resistance A major advantage of using SAE 863 iron copper alloy is its exceptional resistance to wear. The iron-copper composition provides enhanced hardness and strength, making it less susceptible to abrasions, deformations, and surface wear. Components made from SAE 863 are less likely to suffer from damage over time, even in high-friction environments, thus reducing the need for frequent replacements and lowering maintenance costs.

Ensuring high uptime is a first priority at Britvic’s production plants. At their plant in Rugby, Great Britain, Britvic successfully prevented pump failure, optimized asset performance and ensured co...

SAE863Bronze material Properties

863 iron-coppercorrosion resistance

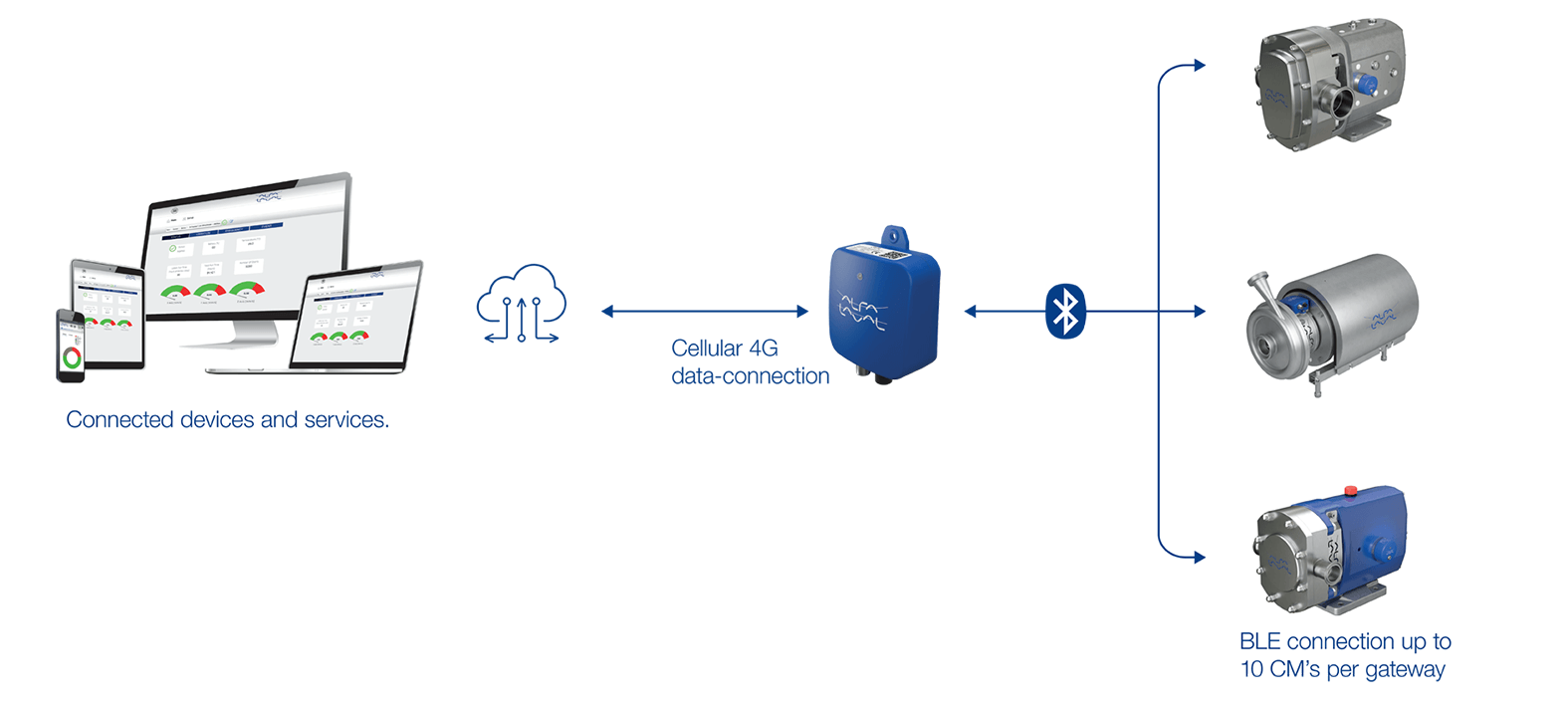

Industries that rely on rotating equipment spend billions on unplanned maintenance. Alfa Laval condition monitoring solutions are intelligent IoT systems that use advanced sensors to measure and collect critical data on machine vibration.

From any remote location, an unlimited number of users can monitor pump condition on PCs and mobile devices. An intuitive user interface and the CM Connect App presents data on an easy-to-understand dashboard and highlights assets in need of attention.

The Sintered Iron Copper Solid Round Bar Stock (SAE 863) is crafted to meet the needs of rigorous industrial applications, providing an exceptional combination of durability, strength, and wear resistance. This unique alloy is designed for applications where load-bearing capacity, thermal conductivity, and longevity are crucial. Known for its ability to handle heavy loads, SAE 863 iron copper alloy is commonly used in bearings, bushings, and other mechanical components subjected to continuous movement, high friction, and significant stress.

1. Superior Load-Bearing Capacity Sintered Iron Copper Solid Round Bar Stock (SAE 863) is made specifically to support applications where high-pressure loads are encountered regularly. The composition and structure of this sintered material allow it to bear loads that would exceed the limits of other materials. This makes it a go-to choice in industries such as automotive, construction, aerospace, and manufacturing, where high-stress components need robust materials to perform reliably under extreme conditions.

For complete visibility of pumps in a specific location, users access data and trend analyses using an intuitive web-based dashboard on PCs and mobile devices – anytime, anywhere. The dashboard displays pump health, battery status of the units, historical vibration data for FFT frequency analysis, current and total running hours, and pump information, such as serial number, model and type.

863 iron copperequivalent

Using Alfa Laval service partners ensures easy access to service centres that use genuine Alfa Laval spare parts, maintain equipment reliability, and conduct maintenance under warranty.

Intelligent predictive maintenance systems that monitor the health of critical rotating equipment, such as pumps, reduce the risk of sudden failure and boost uptime and productivity. Alfa Laval condition monitoring systems leverage the internet of things (IoT), connected devices and analytics to maximize process throughput, reduce the total cost of ownership, and increase plant productivity.

Sae863 iron copper

With Alfa Laval condition monitoring systems, plant operators have complete 24/7 visibility of machine health in real time from a remote location. They can predict, prioritize and plan condition-based maintenance activities using actionable machine health data and insights. This prevents equipment failure, optimizes asset performance and ensures production continuity.

4. Self-Lubricating Properties Sintered Iron Copper Solid Round Bar Stock (SAE 863) is engineered to include small, interconnected pores throughout the material. These pores can hold lubricants, giving the material a self-lubricating property that minimizes friction between moving parts. This feature not only extends the lifespan of the material but also reduces the need for constant manual lubrication, which is especially beneficial in hard-to-access or remote locations. Over time, self-lubrication translates to less downtime and more consistent performance.

Alfa Laval Analytics is a leading, AI-based solution for online condition monitoring. Analytics helps you detect potential machine failure before it occurs and diagnose the root cause. The user-friendly and affordable solution brings peace of mind and helps keep your pumps at peak performance at all times.

3. High Thermal Conductivity The copper content in this alloy significantly improves its thermal conductivity, allowing it to dissipate heat effectively. This characteristic is essential in applications where the components are exposed to continuous operation and heat buildup, such as in rotating or sliding mechanisms. Effective heat dissipation helps maintain the efficiency and longevity of machinery, preventing overheating and promoting smoother operation in high-speed settings.

8613869596835

8613869596835