Cause and Symptoms of a Bad Wheel Bearing - how to tell if wheel bearing is bad

SLF offers self-aligning ball bearings with cylindrical and tapered holes in the 12, 22, 13 and 23 series. In bearings with a tapered hole, the taper ratio is 1:12.

The self-aligning ball bearings in the 112 and 113 series are made with a wide inner ring. Attachment is done using dowel pins that engage with the axial groove at one side of the inner ring. In these two bearing series, the bearing hole has a J7 tolerance.

Self aligning ball bearingssizes

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

Self-aligning ballbearing application

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

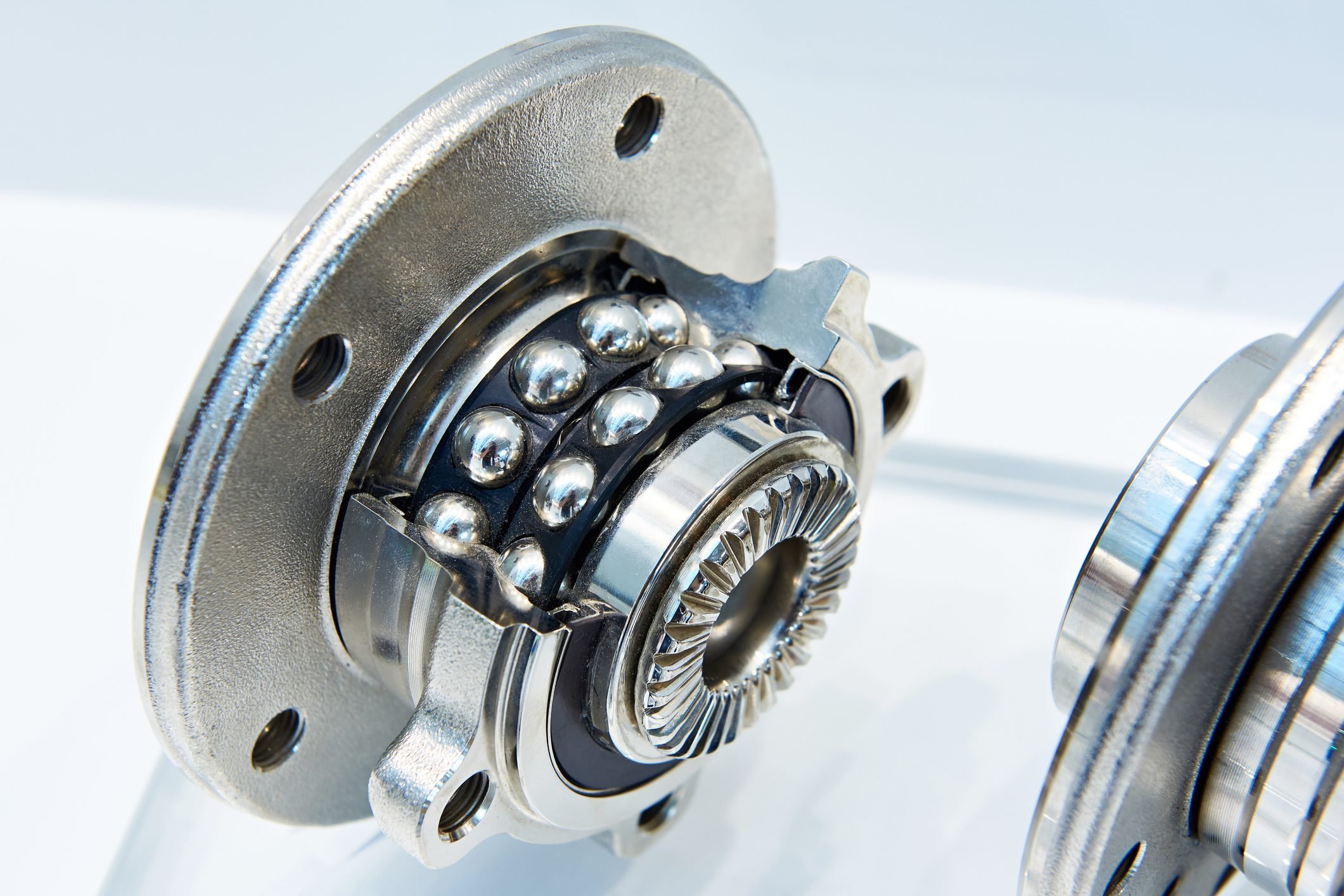

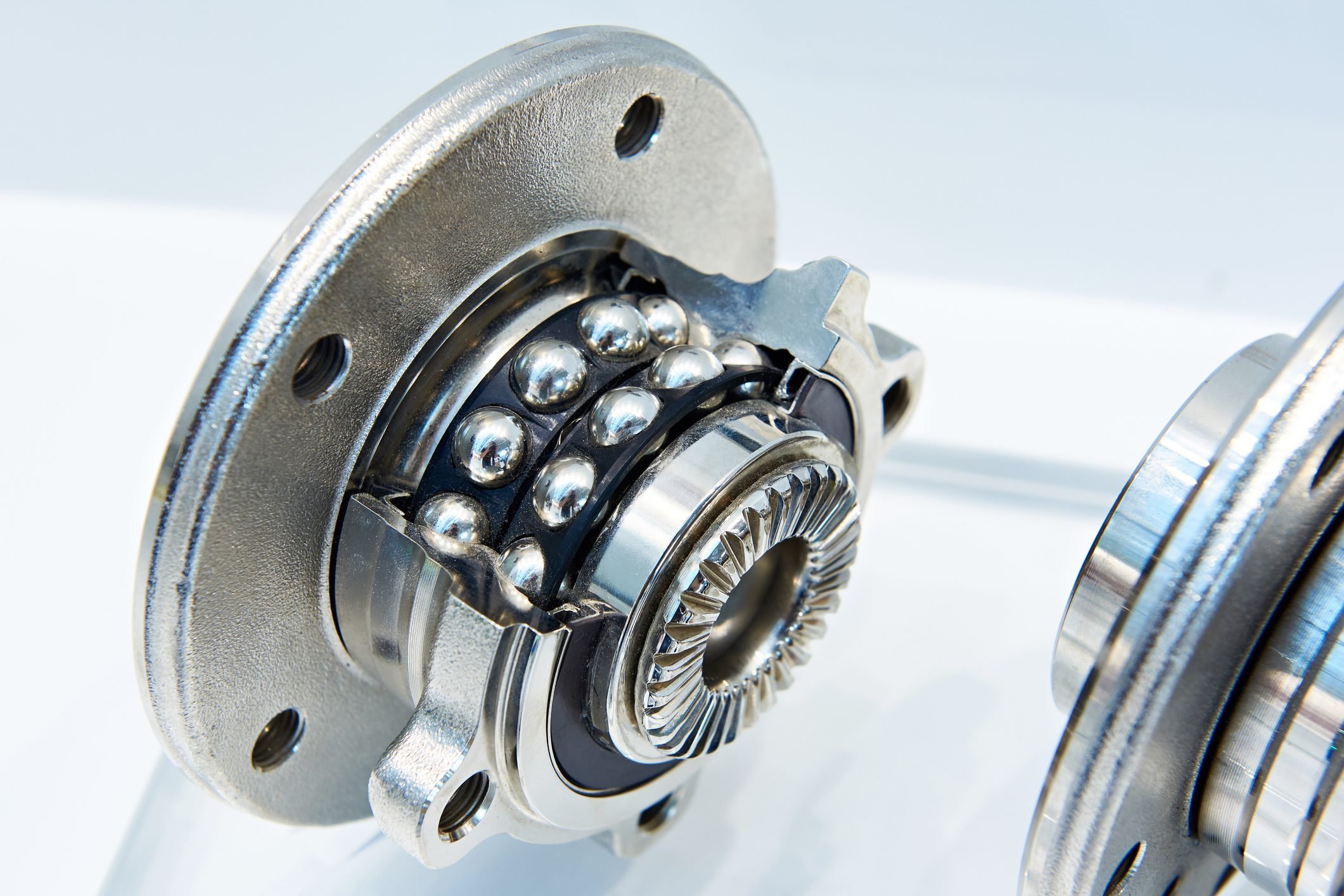

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

self-aligningroller bearing skf

Sealed self-aligning ball bearings (bearings in the 22 … and 23 series) are equipped with contacting sealing on both sides (2RS). They are also standard filled with a high quality lithium-saponified roller bearing grease (bearings with D≤62mm) or a high-performance grease-EP-grease (bearings with D>62mm) based on an age-resistant mineral oil. It is possible to use these bearings at temperatures from -20 °C to max. 110 °C for short periods. When doing this, please note that the operational life of the grease is reduced at a constant temperature >70 °C. In cases like these we recommend special grease customized for the application.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

Self-aligning ball bearings can be designed with fiberglass reinforced polyamide 66 with the designation suffix TV, as well as with a solid brass cage (suffix M). We can also supply individual self-aligning ball bearing types with sheet metal cage (J) upon request. Self-aligning ball bearings with cages made of fiberglass reinforced polyamide 66 (TVP) are suitable for continuously increasing temperatures up to 120 °C. In case of oil lubrication, additives contained in the oil may reduce the operational life of the cage, if the temperature is greater than 100 °C over a longer period.

SLF produces self-aligning ball bearings with standard tolerance (PN) according to DIN 620-2 (Roller bearing tolerances – tolerances for radial bearings) and ISO 492 (Radial bearings – dimensions and tolerances). Please specifically request different tolerance classes or special tolerances.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

self-aligningroller bearing size chart

Self-aligningroller bearing

The reference speed is calculated according to ISO 15312 and is the speed at which, under defined reference conditions, a bearing operating temperature of +70 °C is achieved. It is not a speed limit for the application of a bearing but provides the basis to compare the speed suitability of different bearing types.

In self-aligning ball bearings, the main dimensions are standardized according to ISO 15 (Radial bearings – boundary dimensions), DIN 616 (Roller bearings – boundary dimensions) or DIN 630 (Radial self-aligning ball bearing – double row).

The dimensions of the self-aligning ball bearings with wide inner ring are manufactured according to the standard DIN 630-2, withdrawn without replacement in 1993.

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

Self-aligningbearing types

self-aligningbearing size chart

Self-aligning ball bearings are double-row bearings with two raceways at the inner ring and a joint concave raceway in the outer ring. This design allows for swiveling at various angles, and the bearings of this type are not affected by a slant between shaft and housing. For this reason, they are well suited to arrangements of bearings in which major shaft deflections or misalignments are to be expected.

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

Mostly the radial load resulting from the weight of the components run on bearings combined with the external forces is higher alone than the minimal load required. Should this value not be met, contact an SLF application technician.

In some large-sized self-aligning ball bearing types, the balls slightly protrude laterally; this feature must be considered when dimensioning the surrounding components.

For statically loaded self-aligning ball bearings, always inspect the static load safety factor S0 in addition to the nominal lifetime L (L10h).

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

Self-aligning ball bearings can be swiveled out of the center position by approx. 4°. In sealed bearings, the maximum angle is 1.5°.

For lifetime calculation, in the case of a combined load, insert an equivalent radial load. It is to be determined as follows:

Self aligning ball bearingsprice

20476 Chartwell Center Drive STE C Cornelius, NC 28031 T +1 704 677 7569 F +1 855 710 6774 sales@slfusa.com www.slfusa.com

To avoid slippage between elements in contact, the self-aligning ball bearings must be sufficiently loaded. A minimal radial load in the order of magnitude of

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

For standard, we deliver self-aligning ball bearings according to DIN 620-4 (Roller bearing tolerances – radial clearance) and ISO 5753-1 (Roller bearings – clearance – radial clearance) in the clearance class CN. We can also supply design types in other clearance classes upon request.

SLF-self-aligning ball bearings with a maximum outer diameter up to 240 mm are standard stabilized in size (S0), meaning that they are subjected to heat treatment to make them usable up to a working temperature of 150 °C. At more than 240 mm outer diameter, the self-aligning ball bearings are standard stabilized in dimension (S1), meaning that they are subjected to heat treatment to make them usable up to a working temperature of 200 °C. However, as a rule, the maximum working temperature is not limited by the dimensional stability of the bearing rings and balls. Frequently the limitation is the cage, lubricant, or sealant. For the necessary detailed information, see the corresponding chapters. If you are uncertain or have specific questions regarding the maximal temperature our bearings withstand, don’t hesitate to contact the SLF team.

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

8613869596835

8613869596835