Ceramic Bearings vs Steel Bearings: Performance and ... - ceramic bearings vs steel

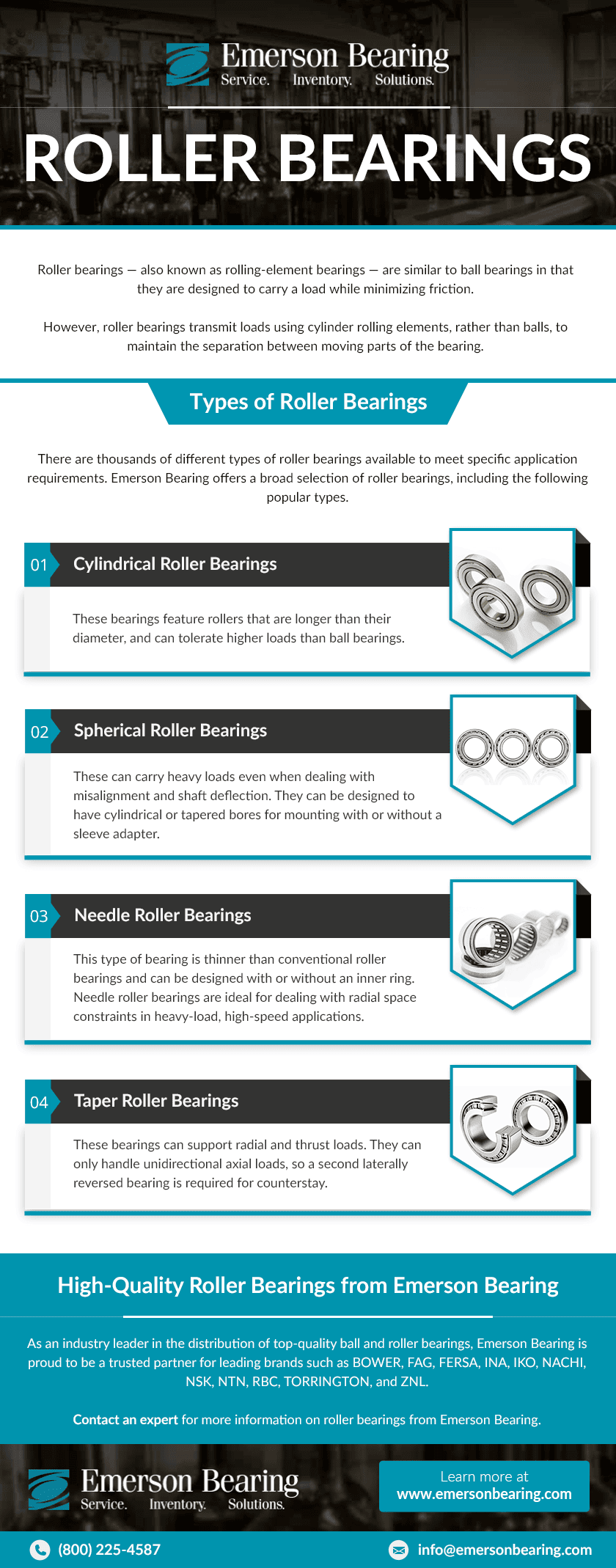

These bearings can support radial and thrust loads. They can only handle unidirectional axial loads, so a second laterally reversed bearing is required for counterstay. Taper roller bearings are available in inch and metric sizes.

Most people recommend that your bearings should be checked every time your brakes are serviced, and that can include things like realigning the bearings to help prevent uneven wear, checking lubrication, and looking for early signs that the bearings are starting to wear out.

A single wheel bearing replacement should cost somewhere between $200-$400, depending on your location and the kind of bearings your vehicle uses.

Our experts are on hand to guide clients in choosing the best type of bearing for their unique needs, and we’ll work closely with your team to ensure you’re selecting the best option. To learn more, reach out to us today.

The best part? CoPilot is built using the same technology that dealerships use to buy and sell their inventories, so we have more info on each vehicle than competitors. CoPilot doesn’t work with dealerships, so there are no sponsored posts or other shady practices — just the most info on the best cars. Check out our About Us page to see how CoPilot works.

This type of bearing is thinner than conventional roller bearings and can be designed with or without an inner ring. Needle roller bearings are ideal for dealing with radial space constraints in heavy-load, high-speed applications. Drawn cup styles allow for high load capacities and large grease reservoirs while still offering a slim cross-section design. These bearings are offered with inch or metric seals.

Ball bearingvsroller bearingapplication

The CoPilot app isn’t just for buying a car - our new CoPilot for Owning tool will help you keep track of recalls and gives you advice on which scheduled maintenance tasks are most important.

A: The time it takes to repair a wheel bearing can vary based on the complexity of the repair and the type of vehicle. However, it typically takes about 15 to 45 minutes per wheel for an easy job, and as long as 90 to 120 minutes for more complex tasks.

If you'd like to learn how bearings are being used in yourindustry, check out our Industry Solutions page which hasdozens of eBooks, charts and data sheets.

Here’s what you need to know about what wheel bearings are, how much repairs cost, and the signs and symptoms that it might be time to get your wheels checked.

Roller bearings — also known as rolling-element bearings — are similar to ball bearings in that they are designed to carry a load while minimizing friction.

View our library that includes our NomenclatureGuide, Vendor Guides, eBooks and much more tohelp with your next project!

Fortunately, quick repairs or replacements usually help prevent excess damage and make it easier to get back on the road.

However, roller bearings transmit loads using cylinder rolling elements, rather than balls, to maintain the separation between moving parts of the bearing.

Taperedroller bearing

By incorporating these practices into your vehicle care routine, you’re not just maintaining your wheel bearings – you’re investing in your car’s overall health and your peace of mind on the road.

However, every once in a while, something will go wrong, and you’ll need to take a closer look at your wheels or get your vehicle to a mechanic so they can check it out.

There are thousands of different types of roller bearings available to meet specific application requirements. Emerson Bearing offers a broad selection of roller bearings, including the following popular types:

Unfortunately, like all bearings, wheel bearings can wear out and occasionally need to be replaced. In fact, replacing them is especially important because a worn bearing can create more friction than your wheels can handle, resulting in damage and even more instability the longer you wait to fix the problem.

While wheel bearings are built to last, proactive care can significantly extend their lifespan and prevent costly repairs. Regular maintenance isn’t just about saving money; it’s about ensuring your safety on the road. Here are some key practices to keep your wheel bearings in top shape:

Roller bearingvs needlebearing

Screeching or rasping noises are two of the most common, but a loud rumble or grumbling sound can also be a sign that your wheel bearings are starting to do.

Now, this symptom is tricky because worn roads can also create more vibration, as can other problems that create friction or instability through your vehicle.

Reducing the friction when you’re driving makes it a lot easier for you to move and steer, so one of the first signs that your wheel bearings are starting to go out is if you’re starting to have more problems steering.

abearingis a very smallrollerbearing.

The answer to this question isn’t as simple as you’d expect. Let’s look explore the difference between gas and diesel engines and explore just how many spark plugs a diesel engine actually has.

These versatile bearings can contain single or multiple rows of rolling elements; multiple rows can significantly improve radial load capacity. Also, the use of different roller shapes can further reduce friction and support both radial and axial loads.

When bearings wear out, it’s usually because they’ve changed shape slightly and are no longer efficient or because their surface has gone brittle and is starting to break apart.

Noticing wheel bearing issues quickly is incredibly important, but a lot of people brush off the most common symptoms of bad wheel bearings.

Unexpected noises are always concerning when it comes to your vehicle, but loud noises from your wheels usually mean that something is going on either in the wheel hub or brake system.

If you catch that your wheel bearing is starting to have trouble quickly, you might just be able to replace one or two of the bearings without needing to fix anything else inside your wheel hub.

Most people know all about tire replacement, at least if they’re car drivers, but a lot of people don’t know much else about how the inside of your vehicle’s wheel works. That’s okay; the majority of the time, you don’t need to know how your wheels are working; you just need to make sure they are.

A: While it’s technically possible, it’s not safe or recommended to drive with a damaged wheel bearing. Doing so can lead to further damage, loss of wheel control, and even accidents.

Uneven tire wear is often a sign that you need to get a wheel alignment, and since alignments need to happen more often than a wheel bearing replacement, you’ll normally be able to fix the problem with an alignment.

If you’re ready to start shopping for a used car and reliability is a priority for you, take a look at our list of the top 10 most reliable used sedans on the market today.

Ball and roller bearingapplication

The accurate diagnosis of a bearing failure is imperativeto prevent repeated failures and their additional expenses.This comprehensive guide to bearing failures outlines themany ways bearings can and do fail.

Ball and Roller BearingCompany

So, it’s important to make sure you replace your wheel bearings as soon as possible after you notice a problem because otherwise, you’ll likely have a much more expensive repair when you get your vehicle to the shop.

Vibration in your steering wheel is another symptom that can point to a variety of problems, but one of the more common ones is wheel bearing wear.

Roller bearings come in a wide range of shapes and sizes, and can be customized for specialized situations. Also, the use of flanges, cages, and multiple bearing rows can allow for higher performance to meet specific application needs.

As an industry leader in the distribution of top-quality ball and roller bearings, Emerson Bearing is proud to be a trusted partner for leading brands such as BOWER, FAG, FERSA, INA, IKO, NACHI, NSK, NTN, RBC, TORRINGTON, and ZNL.

Depending on how quickly you’re able to get your wheel bearing replaced, there are two replacement costs you need to know about.

The problem is when you don’t catch wheel bearing problems fast enough, and you don’t need to just replace the bearings; you need to deal with the damage the broken bearings caused as well.

These bearings feature rollers that are longer than their diameter, and can tolerate higher loads than ball bearings. Our cylindrical roller bearings can carry heavy radial loads and are able to be used in high-speed applications.

© 2025 Emerson Bearing Company | 201 Brighton Avenue, Boston, MA 02134 | Phone (800) 225-4587 | info@emersonbearing.comSite created by ThomasNet RPM | Privacy Policy | Sitemap

A typical wheel bearing is either a metal sphere or a metal cylinder that can rotate freely to help reduce friction. There are several of them in all of your wheels; anywhere two surfaces would touch while the vehicle is moving. That way, the friction turns the bearing, which both reduces the friction and helps prevent overheating.

All the wheels on your vehicle have bearings, and that’s important for helping reduce the friction between moving parts and to help keep your ride smoother and quieter.

Your wheel bearings or wheel hub will likely need to be replaced every 85,000-100,000 miles if they’re sealed, which prevents maintenance but also helps the bearings last a little longer.

Roller bearingvsball bearingfriction

One of the sources of those problems is often the wheel bearings. Since your wheel bearings deal with a lot of the wear and tear work of wheel rotation, it’s not abnormal for them to eventually wear out and need replacement.

These can carry heavy loads even when dealing with misalignment and shaft deflection. They can be designed to have cylindrical or tapered bores for mounting with or without a sleeve adapter. Available with various internal clearances and retainer options, spherical roller bearings can handle axial loading in either direction as well as heavy shock loads. These bearings are available in bore dimensions ranging from 20 mm to 900 mm.

However, if you also need to replace the wheel hub, which houses the bearings, it will typically cost between $200-$500 depending on the hub and wheel type.

No matter how the bearing is starting to wear, wearing out will reduce the efficiency and create more friction, heat, and roughness while you’re driving.

A: Common signs include a humming or rumbling noise that increases with speed, a loose or vibrating steering wheel, uneven tire wear, and the ABS light turning on.

The CoPilot car shopping app is the easiest way to buy a car. Tell us what you’re looking for and we’ll search the inventories of every dealership in your area to make you a personalized list of the best car listings in your area.

Cylindricalroller bearing

Only looking for newer models? CoPilot Compare is the search engine for nearly-new cars. Only see cars five years or newer with low mileage — CoPilot Compare is the best way to find off-lease, early trade-in, and CPO cars.

Wheel bearings are one of the parts of your vehicle that a lot of people don’t think about much, partially because it’s common for people not to know that your bearings are part of a brake service.

While roller bearings can handle higher loads than conventional ball bearings, their applications are generally limited to low-speed operations. Many types of roller bearings are self-aligning, and are easily able to overcome misalignment and mounting issues — cutting down on maintenance, repair, and labor needs.

For other wheel hubs and bearings, the replacement schedule is a little more variable and also depends on the kind of driving you do, in addition to how many miles you’ve driven.

A: Generally, car insurance does not cover wheel bearing repair as it’s considered part of regular maintenance. However, if the damage was caused by an accident, it might be covered under your policy.

That’s because the extra friction from a worn wheel bearing gets transferred through your entire vehicle, especially the wheel assembly and steering system.

However, uneven tire wear can also be a sign that your wheel bearings are going out, especially if the wear seems to only affect one tire.

Roller bearings are used in a wide range of applications, from heavy equipment and machinery to power generation, manufacturing, and aerospace.

A: While it’s possible to repair a wheel bearing yourself if you have the right tools and knowledge, it’s generally recommended to have this kind of repair done by a professional mechanic to ensure it’s done correctly and safely.

8613869596835

8613869596835